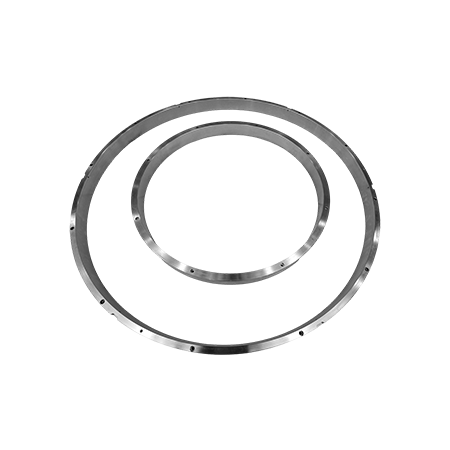

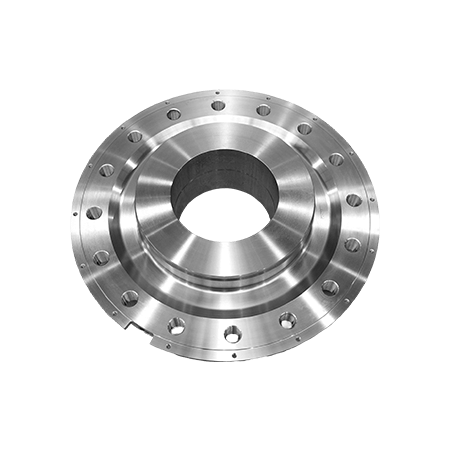

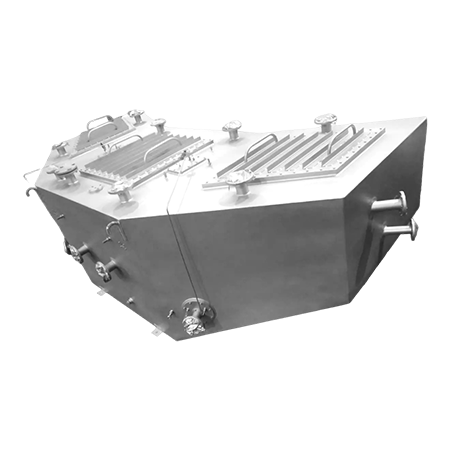

Casting Series

One-piece rotor, carbon steel forging, this design improves the overall structural performance and greatly saves the assembly time of the rotor and the connecting plate; the part is large in size and weighs more than 1 ton; the precision requirement is extremely high and the processing difficulty is very high

What Are Castings?

In the intricate world of manufacturing and engineering, castings are the fundamental building blocks of innovation. A casting is a metal object produced by pouring molten metal into a mold, where it cools and solidifies into the desired geometric shape. This process, one of the most ancient and yet most versatile manufacturing techniques, allows for the creation of complex and intricate parts that would be difficult or cost-prohibitive to produce through other methods like machining or fabrication.

From the robust engine block in your vehicle to the intricate components in aerospace assemblies, castings are the unsung heroes of our modern world. They offer immense design freedom, enabling the production of parts with complex internal cavities, variable wall thicknesses, and streamlined, organic shapes. The choice of metal—be it iron, steel, aluminum, brass, or exotic alloys—further allows for a precise tuning of mechanical properties, including strength, durability, corrosion resistance, and weight. At its core, casting is the art of transforming liquid metal into a solid, functional, and reliable component that meets the most demanding specifications.

The Art and Science of Casting: Processes and Critical Considerations

The journey from molten metal to a finished part is a highly technical process fraught with challenges that demand deep expertise. The quality of the final casting is contingent upon a meticulous understanding of metallurgy, fluid dynamics, and thermodynamics.

Key Process Applications:

Our expertise spans a wide array of casting processes to suit diverse application needs:

Sand Casting:

Ideal for large, heavy, or complex parts, offering versatility and cost-effectiveness for a wide range of ferrous and non-ferrous metals.

Investment Casting (Lost-Wax):

Unparalleled in its ability to produce parts with exceptional surface finishes and intricate details, minimizing the need for secondary machining. It's the go-to process for aerospace, medical, and high-performance components.

Die Casting:

Perfect for high-volume production of non-ferrous parts, delivering high-speed, repeatable results with excellent dimensional accuracy.

Centrifugal Casting:

Used to create cylindrical parts with high material density and purity, as impurities are forced to the center and machined away.

Critical Considerations in Casting and Machining:

Achieving a flawless casting requires navigating several potential issues. A deep understanding of these challenges is what separates the amateur from the expert:

Porosity:

The formation of tiny voids or holes within the metal can compromise structural integrity. This is controlled through precise temperature management, gas evacuation from the mold, and optimized pouring techniques.

Shrinkage:

All metals shrink as they cool. Managing this requires sophisticated mold design, including the strategic placement of "risers" that feed molten metal to the casting as it solidifies.

Surface Finish:

The texture of the final part is critical for both aesthetics and function. We control this through careful mold material selection, preparation, and, when required, advanced secondary machining and finishing processes.

Dimensional Accuracy:

Ensuring the final part meets tight tolerances is paramount. This involves accounting for thermal contraction, meticulous mold construction, and precision CNC machining for critical features.

Our Meticulous Casting Process: A Symphony of Precision

We believe that superior outcomes are born from a superior process. Our end-to-end workflow is designed for transparency, quality, and uncompromising precision at every stage.

Consultation & Design for Manufacturability (DFM):

It all begins with your concept. Our engineers collaborate with your team to analyze your design, material specifications, and performance requirements. We provide critical DFM feedback to optimize the part for casting, ensuring better quality, reduced cost, and faster turnaround.

Pattern & Mold Making:

Leveraging advanced CAD/CAM software and CNC machining, we create a highly accurate pattern—the master model of your part. This pattern is then used to create a precision mold, the negative space that will shape the final product.

Melting & Pouring:

We select the certified alloy that meets your exact specifications and melt it in a state-of-the-art furnace. The molten metal's temperature and chemical composition are rigorously monitored before it is poured into the mold with a controlled, consistent flow to prevent defects.

Solidification & Shakeout:

After pouring, the casting is allowed to cool under controlled conditions to ensure optimal metallurgical structure. Once solidified, the casting is removed from the mold in a process called shakeout.

Finishing & Heat Treatment:

The raw casting is then finished to remove any excess material. Depending on the requirements, it may undergo various heat treatments—such as annealing or quenching—to enhance its mechanical properties like hardness and ductility.

Precision CNC Machining:

For features that require tolerances beyond what casting can achieve, our in-house CNC machining centers take over. We perform precision milling, turning, drilling, and grinding to bring every critical dimension into perfect alignment with your blueprint.

Rigorous Quality Assurance:

Quality is not just a final check; it's embedded in every step. We utilize a suite of inspection tools, including Coordinate Measuring Machines (CMM), X-ray inspection (for internal integrity), and spectrographic analysis (for material verification), to ensure your parts are flawless before they leave our facility.

Why Partner With Us?

Choosing a casting and machining partner is a critical decision. Here’s why industry leaders trust us with their most demanding projects:

Integrated Turnkey Solutions:

From design consultation to a fully machined and finished component, we are your single-source supplier. This streamlined approach simplifies your supply chain, reduces lead times, and ensures seamless accountability.

Unwavering Commitment to Quality:

Our ISO 9001 certified quality management system is the backbone of our operations. We don't just inspect for quality; we build it into the process, guaranteeing parts that are reliable, repeatable, and ready for service.

Deep Metallurgical & Engineering Expertise:

Our team consists of seasoned engineers and metallurgists who understand the nuances of how different alloys behave under various conditions. We provide the expert guidance you need to select the right material and process for optimal performance and cost-efficiency.

State-of-the-Art Technology:

We continuously invest in the latest casting, machining, and inspection technologies. This commitment allows us to handle complex geometries, meet sub-millimeter tolerances, and deliver superior results that give you a competitive edge.

A True Partnership Approach:

We view our clients as partners. We are committed to open communication, responsive service, and a collaborative spirit to ensure your project's success is our shared success.

Let's build the future together. Contact our engineering team today to discuss your next project and discover the difference that true craftsmanship and precision can make.