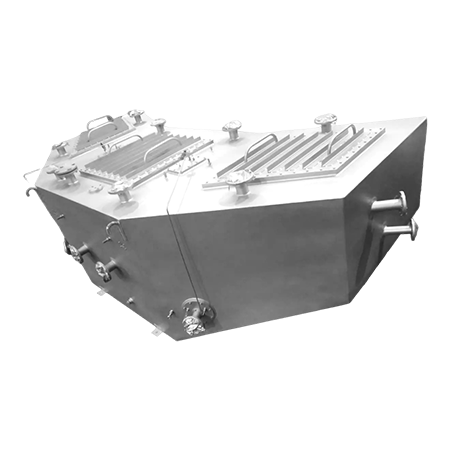

Generator rotor series

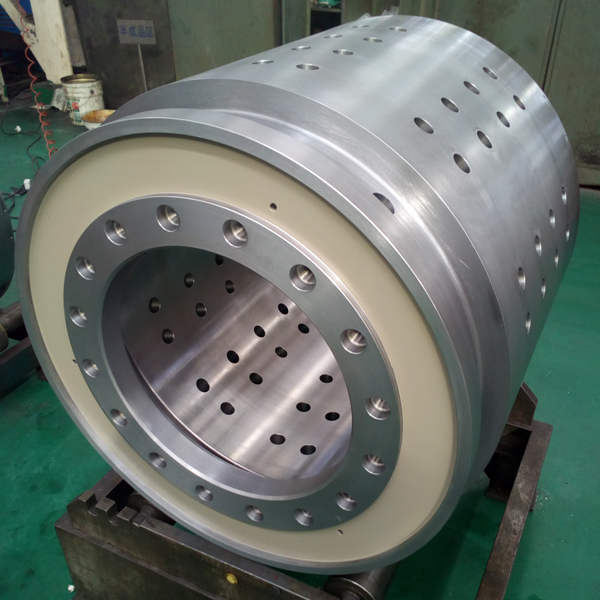

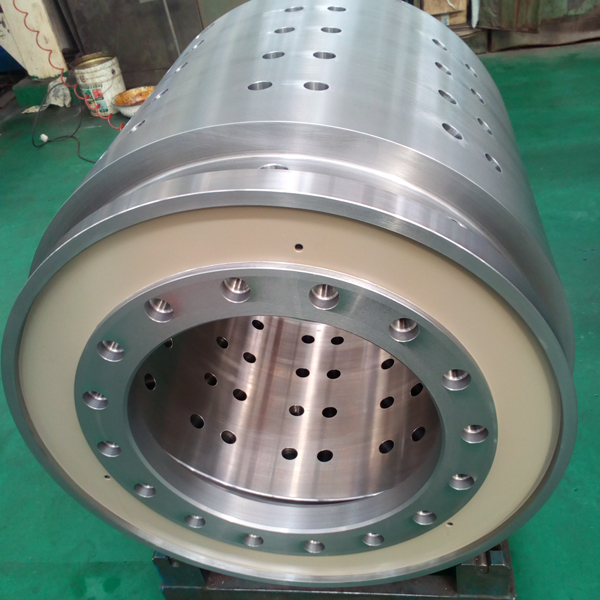

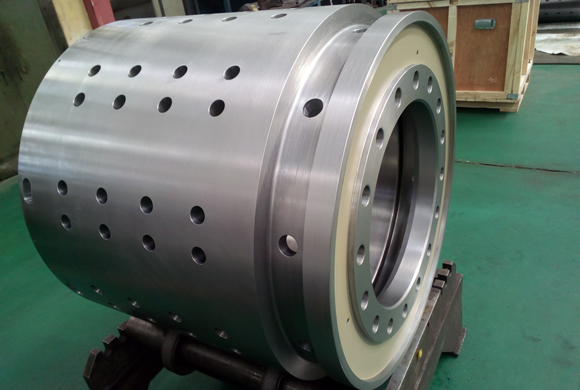

Integral rotor, carbon steel forging, this design improves the overall structural performance, greatly saving the assembly time of the rotor and the connecting plate; the part size is large, weighing over one ton, the minimum size tolerance required is 0.025mm, the position tolerance is 0.03mm, the precision requirement is extremely high, and the processing difficulty is very great.

What is a Generator Rotor?

The generator rotor is the dynamic, rotating component within a generator that, through the principles of electromagnetic induction, converts mechanical energy into electrical energy. As it spins, its magnetic field interacts with the stationary stator, inducing an electrical current. The efficiency, stability, and longevity of a generator are all directly linked to the quality and precision of its rotor.

Traditionally, rotors were often assembled from multiple parts, including a main shaft and a separate connection disc. However, our focus is on the superior single-piece (integral) rotor design. Forged from a solid piece of high-grade carbon steel, this innovative approach eliminates the need for assembly, creating a monolithic structure. This design significantly enhances the overall structural performance, eradicates potential points of failure associated with assembled components, and dramatically reduces the time that would otherwise be spent on complex and critical assembly procedures. The result is a more robust, reliable, and efficient core for any power generation system.

The Art of Precision: The Unique Challenges of Rotor Machining

Manufacturing a generator rotor of the scale and precision we handle is a task that pushes the boundaries of modern machining. The challenges are formidable, demanding not only state-of-the-art equipment but also a deep well of engineering expertise and process control.

A Symphony of Scale and Precision:

Our rotors are substantial, with the raw carbon steel forgings weighing in at over a ton. Maneuvering and machining a workpiece of this magnitude while achieving microscopic accuracy is a significant engineering feat. The sheer mass of the component introduces challenges related to stability, heat dissipation, and the immense forces exerted during machining.

Exacting Tolerances on a Grand Scale:

The true difficulty lies in the extraordinary precision required. We are tasked with achieving dimensional tolerances as fine as 0.025mm and positional tolerances of 0.03mm. To put this into perspective, this is less than half the width of a human hair, applied to a component that weighs more than a small car. Any deviation beyond these minute margins can lead to imbalances, excessive vibration, and ultimately, catastrophic failure of the generator. This level of ultra-high precision on such a large scale presents a unique and demanding manufacturing challenge that few can meet.

Our Blueprint for Perfection: A Meticulous Machining Process

To overcome these challenges, we have developed a comprehensive and rigorously controlled machining process. Each step is meticulously planned and executed by our team of seasoned engineers and technicians to ensure the final product meets and exceeds the most stringent quality standards.

Raw Forging Inspection and Preparation:

Our process begins with the receipt of the single-piece carbon steel forging. Each forging undergoes a rigorous ultrasonic and magnetic particle inspection to ensure it is free from any internal defects. This foundational step guarantees the material integrity required for a high-stress rotational component.

Rough Machining and Stress Relieving:

The initial machining phase involves removing large amounts of material to bring the rotor closer to its final shape. This is performed on heavy-duty CNC lathes and milling centers capable of handling the immense weight and scale. Following rough machining, the rotor undergoes a controlled heat treatment process to relieve internal stresses induced during forging and machining, ensuring dimensional stability for the high-precision work to follow.

Semi-Finish and Precision CNC Machining:

With the bulk of the material removed and internal stresses normalized, the rotor moves to our advanced multi-axis CNC machining centers. Here, critical features are machined to near-final dimensions. Our climate-controlled facility and thermally stable machines mitigate the effects of thermal expansion, a critical factor in maintaining tight tolerances on large parts.

High-Precision Finish Grinding:

To achieve the final, exacting surface finishes and dimensional tolerances of 0.025mm, the rotor undergoes a precision grinding process. Using specialized grinding machines, our expert machinists carefully remove the last few microns of material, producing a flawless surface and ensuring all diameters and geometric features are perfectly within specification.

Dynamic Balancing and Final Inspection:

Even with perfect dimensions, a rotor's weight distribution must be perfectly uniform. The rotor is placed on a dynamic balancing machine, which spins it at various speeds to detect the slightest imbalance. Microscopic amounts of material are then precisely removed until the rotor is in perfect harmony. The final stage involves a comprehensive quality assurance check using Coordinate Measuring Machines (CMM) and other advanced metrology equipment to verify every dimension, position, and tolerance against the design specifications.

Why Partner with Us?

Choosing a manufacturing partner for a component as critical as a generator rotor is a decision that rests on trust, capability, and a proven track record. Here’s why we are the premier choice for your high-precision rotor needs:

Mastery of Complexity:

We specialize in the difficult. Machining a one-ton component to a tolerance of 0.025mm is not just a capability; it is our area of expertise. We have the specialized equipment, the controlled environment, and the institutional knowledge to handle projects of this magnitude and complexity.

Commitment to the Single-Piece Advantage:

We champion the superior integral rotor design. Our process is optimized to handle these large, single-piece forgings, ensuring our clients benefit from the enhanced structural integrity, reliability, and reduced assembly time this design offers.

Unwavering Dedication to Quality:

From initial material inspection to final dynamic balancing, quality control is embedded in every step of our process. Our rigorous inspection protocols and advanced metrology ensure that every rotor we deliver is a testament to precision and reliability.

Deep Engineering Expertise:

Our team consists of highly skilled engineers and machinists who understand the unique physics and challenges of large-part manufacturing. This expertise allows us to develop innovative solutions and continuously refine our processes for optimal results.

When the heart of your operation demands perfection, trust the experts who engineer precision on a grand scale. Partner with us to power the future with unparalleled quality and performance.