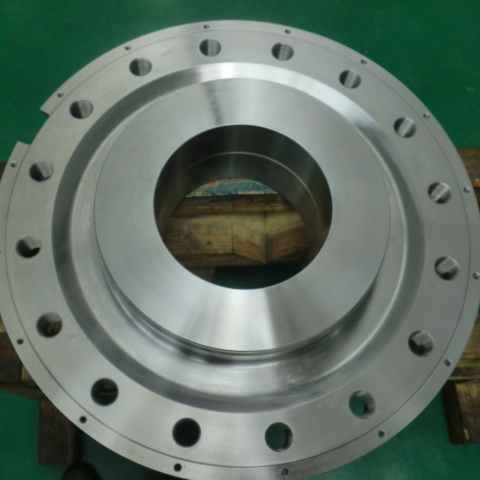

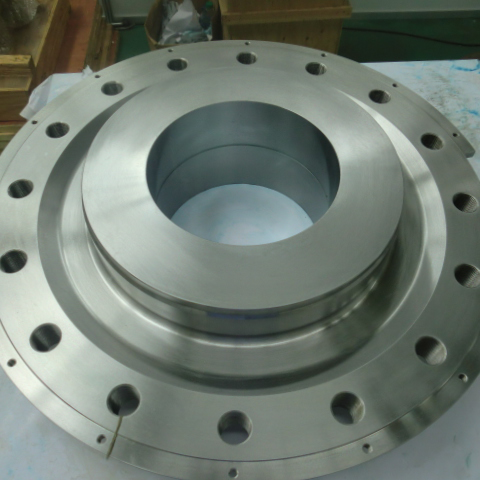

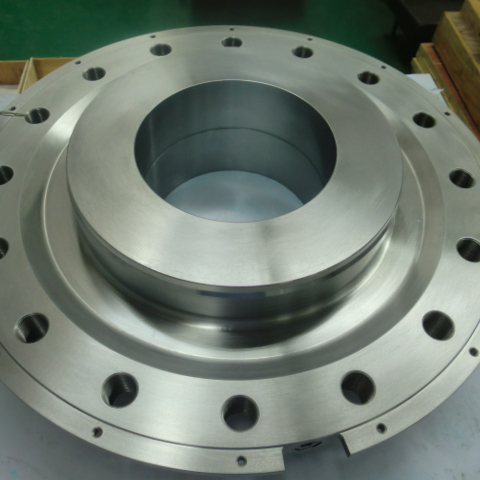

Engine flywheel series

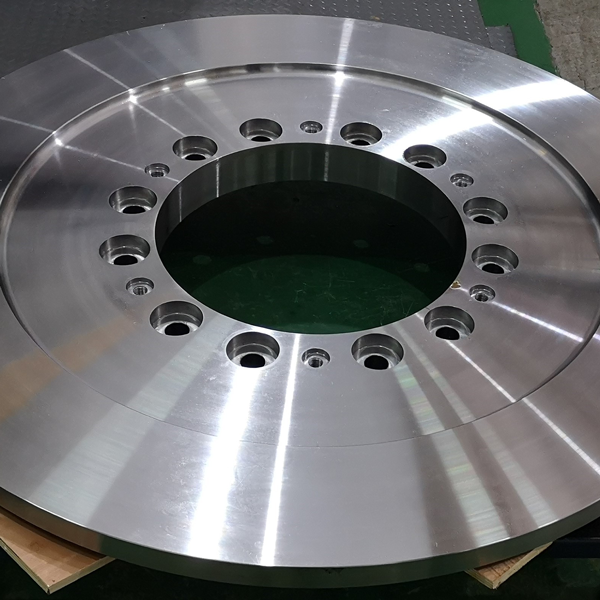

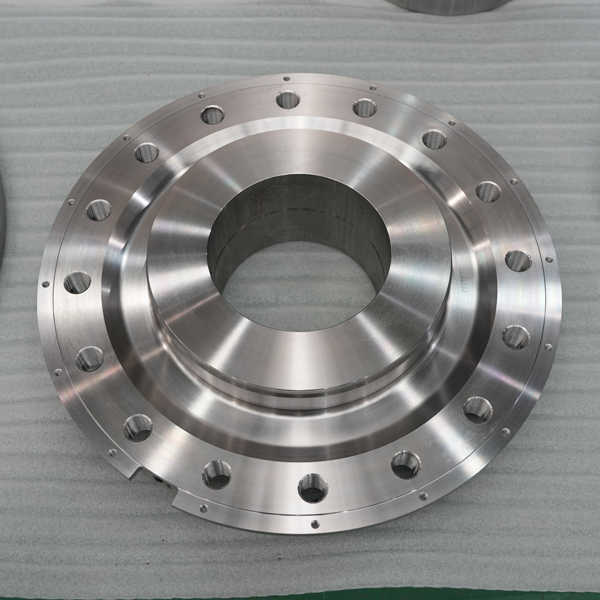

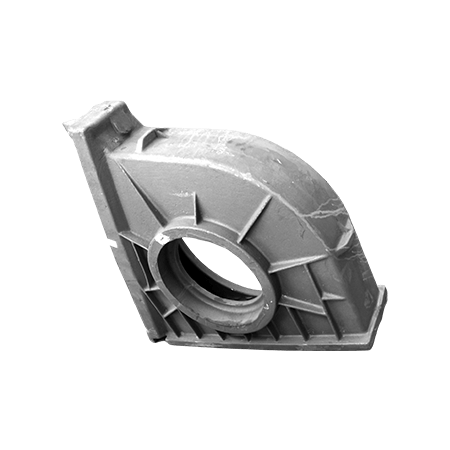

Large flywheel, alloy steel forging, the fit rate of the central conical hole and the cone sleeve must exceed 80%, the axial size tolerance of the fit is only 0.5mm, the error in the diameter direction is less than 0.01mm, the precision is high; the technical requirements are relatively complex, including electro-pulse plating, balancing, non-destructive testing, etc.

What is an Engine Flywheel?

An engine flywheel is a heavy, precisely balanced wheel that mounts to the end of the crankshaft.

Its primary role is to store rotational energy. In a reciprocating engine, power is delivered in short,

explosive bursts as each cylinder fires. This creates a fluctuating, jerky rotation. The flywheel, with its

significant mass, smooths out these power pulses. It absorbs energy when the engine speeds up and releases it

when it slows down between combustion strokes, resulting in a consistent, stable output. ;

This Function Is Critical For Several Reasons

It dampens vibrations, leading to a smoother,quieter, and more reliable engine performance.

In essence, without a perfectly functioning flywheel, a powerful engine would be rough, inefficient, and prone to premature failure.

The Art of Precision: The Unique Challenges of Flywheel Machining

Crafting a large-scale engine flywheel is a process where immense forces and minute details intersect. The technical complexity far surpasses that of standard machining, demanding specialized knowledge and cutting-edge technology.

Material Strength & Machinability:

We begin with high-strength forged alloy steel. Forging aligns the steel's grain structure, creating a component with exceptional durability and fatigue resistance, capable of withstanding the colossal torque and cyclical stresses of a large engine. However, this inherent toughness makes it incredibly challenging to machine. It requires powerful equipment, specialized cutting tools, and a deep understanding of metallurgy to cut and shape without compromising the material's integrity.

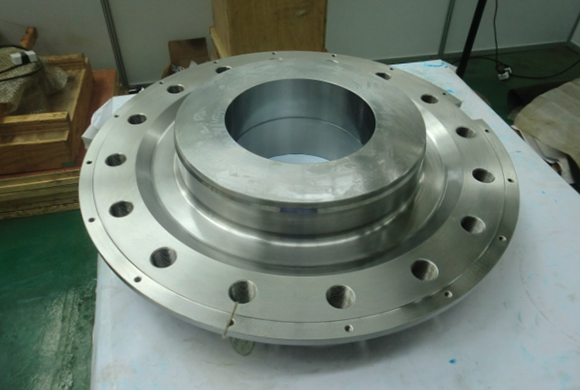

The Pinnacle of Precision - The Central Tapered Bore:

The most critical feature of a flywheel is its connection to the crankshaft. We specialize in machining a highly precise central tapered bore designed to mate flawlessly with a corresponding tapered sleeve. Our engineering standard demands that the contact fit between these two surfaces exceeds 80%. This extensive surface contact is paramount for ensuring a solid, unyielding connection that can transfer maximum torque without slip or vibration.

Tolerances Measured in Microns:

In large flywheel manufacturing, precision is not a goal; it is a prerequisite. Our machining capabilities are defined by tolerances that leave no room for error:

An axial dimension tolerance of only 0.5mm ensures the flywheel is perfectly positioned within the engine assembly, preventing misalignment with the clutch and starter motor.

A radial runout error of less than 0.01mm (10 microns). This incredible precision in the diameter ensures the flywheel spins perfectly true, eliminating wobble and destructive vibrations at high RPMs.

Complex Secondary Processes:

The technical requirements extend beyond just machining. Our flywheels undergo a suite of advanced treatments, including a specialized electro-pulsed plating process. This advanced coating technique provides a durable, uniform, and corrosion-resistant finish that far surpasses conventional painting. Furthermore, every flywheel is subjected to rigorous dynamic balancing to eliminate even the slightest imbalance, and comprehensive Non-Destructive Testing (NDT) to guarantee absolute structural integrity.

Our Meticulous Manufacturing Process

To meet these exacting standards, we have developed a comprehensive, multi-stage manufacturing process where quality is embedded at every step.

Material Validation:

We begin by sourcing premium forged alloy steel billets. Upon arrival, each billet undergoes non-destructive testing to ensure it is free from internal voids, inclusions, or other flaws.

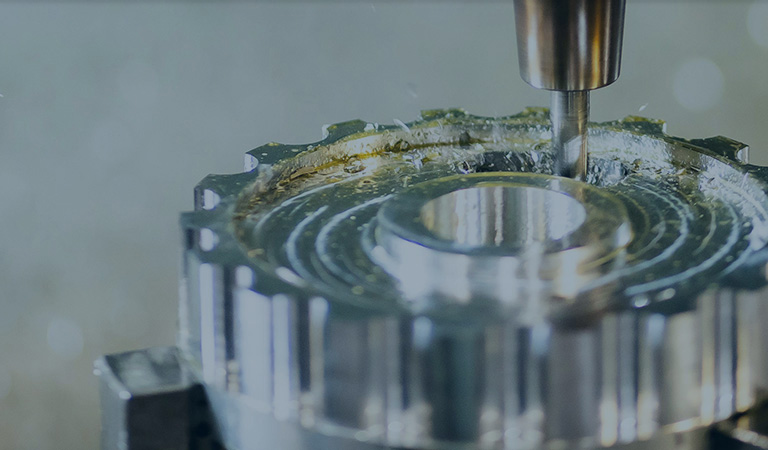

CNC Rough & Finish Machining:

The billet is loaded into our state-of-the-art CNC turning centers. The initial rough machining shapes the flywheel's basic profile. This is followed by meticulous finish machining, where critical features like the central tapered bore, mounting holes, and clutch face are cut to their exacting dimensions.

Advanced Surface Treatment:

The machined flywheel then proceeds to our specialized coating facility. Here, the electro-pulsed plating is applied under tightly controlled conditions, ensuring a flawless and resilient surface finish that protects against the harsh engine environment.

Precision Dynamic Balancing:

Post-coating, each flywheel is individually spun on our dynamic balancing machines. Sophisticated sensors detect the slightest imbalance, which our technicians correct by precisely removing or adding minute amounts of material. This process is repeated until the flywheel achieves a state of near-perfect equilibrium.

Final Quality Assurance & NDT:

The final stage is our most rigorous. A suite of metrology tools verifies every critical dimension, confirming the axial tolerance (0.5mm), radial runout (<0.01mm), and the integrity of the tapered bore (>80% fit). A final round of Non-Destructive Testing, such as Magnetic Particle Inspection, is performed to certify that the flywheel is structurally perfect and ready for service.

Why Partner With Us?

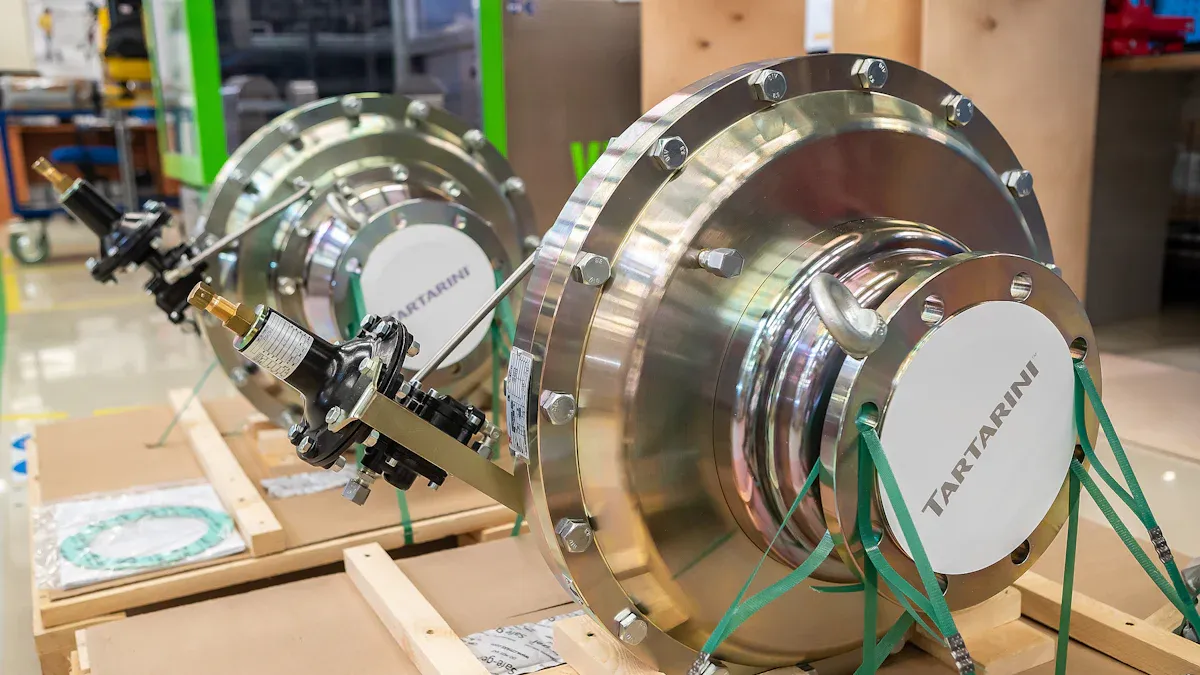

Choosing a manufacturing partner for a mission-critical component like a large engine flywheel is a decision that impacts performance, reliability, and your bottom line. Here's why we are the industry leader

Uncompromising Precision:

We don't just meet standards; we set them. Our mastery of tolerances, including the critical 0.01mm radial runout and the >80% taper fit, is a testament to our commitment to excellence.

Expertise in Demanding Applications:

We thrive on complexity. Our team possesses deep expertise in machining large-scale components from challenging materials like forged alloy steel, ensuring superior results every time.

Integrated, End-to-End Solutions:

From raw material sourcing to advanced coatings, balancing, and NDT, we manage the entire manufacturing process in-house. This guarantees seamless quality control, streamlines communication, and provides our clients with a single, reliable point of contact.

Investment in Technology:

Our facility is equipped with the latest in CNC machining, advanced metrology, and specialized finishing technologies, enabling us to tackle the most demanding projects with confidence.

Entrust your most critical components to a partner who understands that true power lies in precision.