Home / Resources / Blogs / Industry News / How to choose an upflow pressure screen? An easy-to-understand industry guide

How to choose an upflow pressure screen? An easy-to-understand industry guide

As a "high-performance expert" in the field of industrial screening, upflow pressure screens are widely used in chemical, food, pharmaceutical, environmental protection and other industries. However, there are a variety of equipment models on the market. How should our company choose equipment that suits its production needs?

1. Clarify the needs: What to screen? How to screen?

Application scenarios

The purpose of the upflow pressure screen directly affects the selection. For example:

Chemical industry: corrosion-resistant, high-precision metal screens (such as stainless steel) are required for the separation of materials such as catalysts and pigments.

Food and medicine: give priority to plastic or ceramic screens that are easy to clean and meet hygienic standards to avoid pollution.

Environmental protection field: wastewater with high viscosity or impurities needs to be treated, and attention should be paid to the anti-blocking ability and processing capacity of the equipment.

Screening requirements

Precision: fine screens (such as 0.15mm screen gaps) are suitable for high-precision needs (such as pharmaceutical raw materials), and coarse screens are used for preliminary sorting.

Processing capacity: Choose a model according to the scale of production. For example, the daily processing capacity of the ZNL series pressure screen ranges from 15 tons to 180 tons.

2. Look at performance: both efficiency and durability

Screen material and life

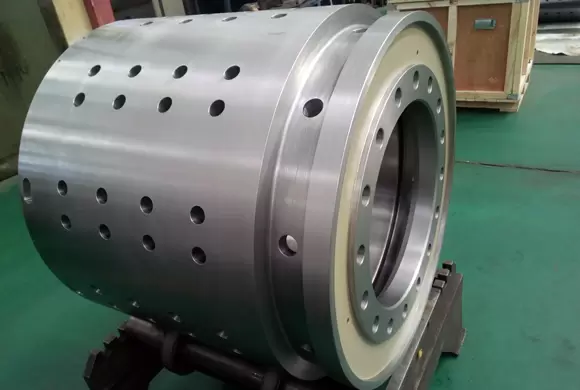

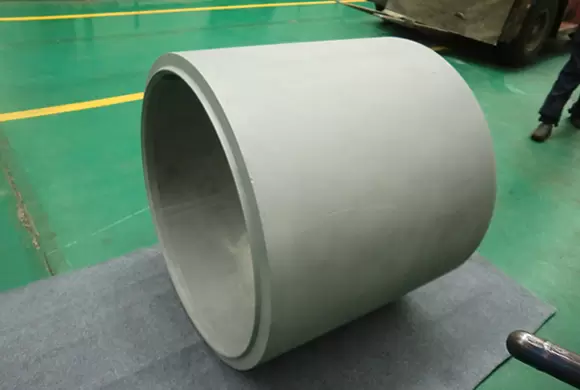

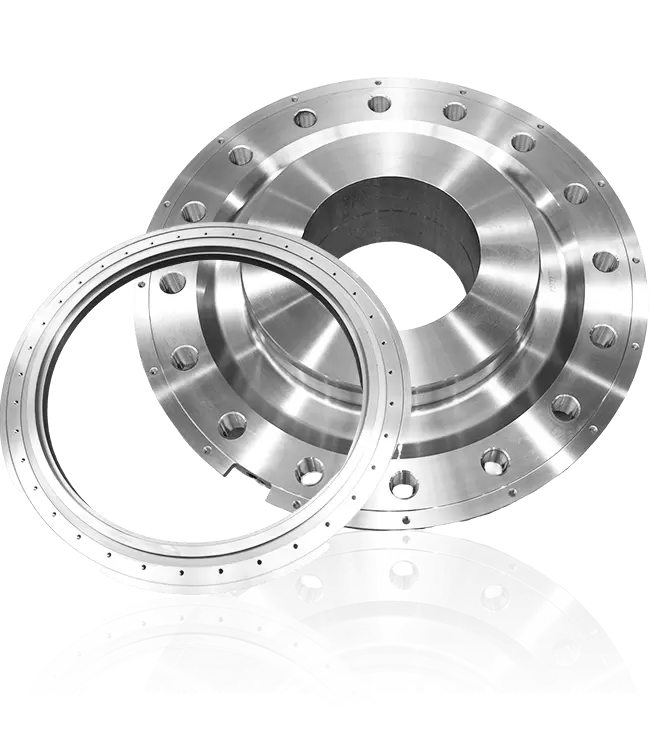

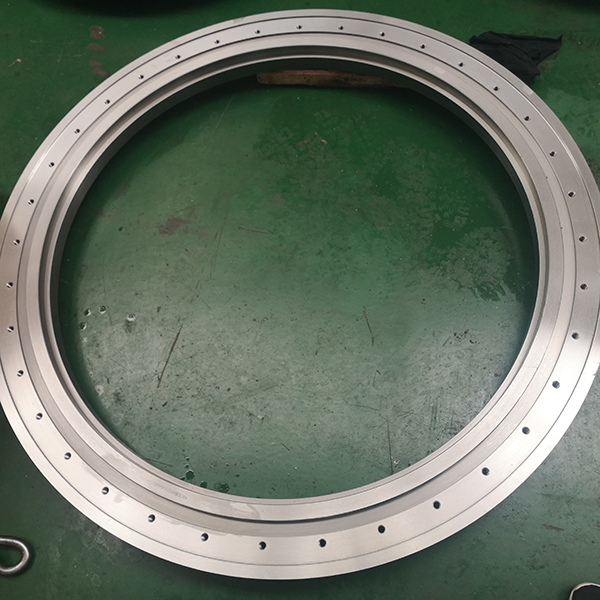

Metal screens (such as stainless steel) are highly wear-resistant, but the cost is relatively high; plastic screens are lightweight and corrosion-resistant, suitable for short-term high-frequency use. Some manufacturers use a "corrugated screen slit design" to maintain high output even with small gaps and reduce the risk of blockage.

Energy saving and maintenance

The new generation of equipment is generally equipped with an intelligent control system that can adjust the vibration frequency and pressure to reduce energy consumption (for example, the energy consumption of a certain brand of intelligent equipment is 20% lower than that of traditional models).

Choosing models that are easy to maintain, such as the spindle with mechanical sealing technology, can reduce downtime and maintenance time by 9.

3. Choose a brand: reputation and service are the key

Technical strength and cases

Give priority to brands with mature technology accumulation. For example, the high-concentration pressure screen of a leading domestic company has a market share of more than 30% in the chemical industry, and its customers include international giants such as BASF.

Reference to actual cases: After a food company adopted a certain brand of pressure screen, the product qualification rate increased by 15% and the failure rate decreased by 40%.

After-sales service

Perfect after-sales support (such as installation guidance and regular maintenance) can greatly reduce operational risks. For example, some manufacturers provide "1 to 1 technical training" and 24-hour response services.

Pay attention to policies and trends

Environmental compliance

With the advancement of the country's "dual carbon" policy, choosing low-energy consumption and low-pollution models is more in line with long-term needs. For example, some equipment reduces wastewater discharge by optimizing pressure design.

Intelligent upgrade

In the future, pressure screens will develop in the direction of automation and dataization. For example, the intelligent screening system launched by a manufacturer can monitor the status of the screen in real time and warn of failures in advance.

Summary

When choosing an upflow pressure screen, it is necessary to start from actual needs, comprehensively consider performance, brand services and policy guidance. It is recommended that enterprises compare actual measured data, participate in industry exhibitions (such as the 2025 Shanghai Industrial Catalyst Exhibition) to inspect equipment on site, and communicate with suppliers in depth about customized solutions811. Only by "tailoring to the needs" can the equipment truly become a "powerful assistant" for the production line.