Home / Resources / Blogs / Industry News / Precision Engineering: Tailored Machining of Generator Rotors for Optimal Efficiency

Precision Engineering: Tailored Machining of Generator Rotors for Optimal Efficiency

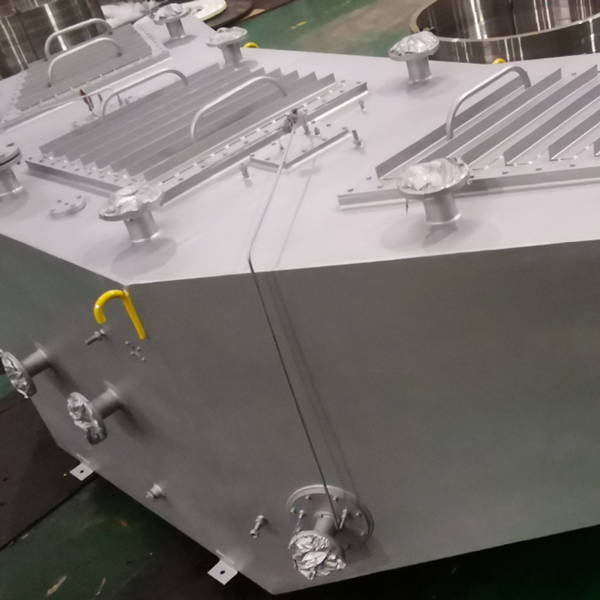

In the realm of precision engineering, where every micron counts and performance is paramount, customized machining of generator rotors stands as a testament to the marriage of advanced technology and bespoke solutions. At Jiangxi Hongdu Preciosion Machinery cutting-edge facility, we specialize in the tailored manufacturing of generator rotors, ensuring optimal efficiency and reliability tailored specifically to your unique requirements.

The Art and Science of Customization

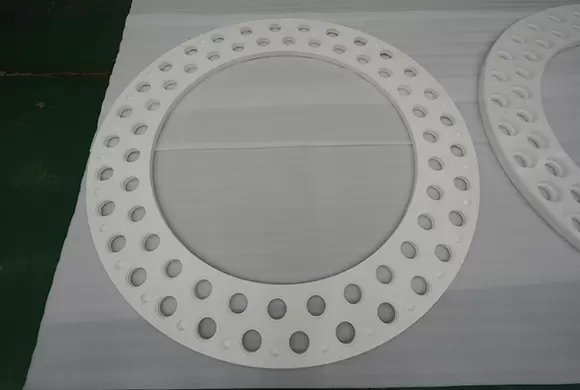

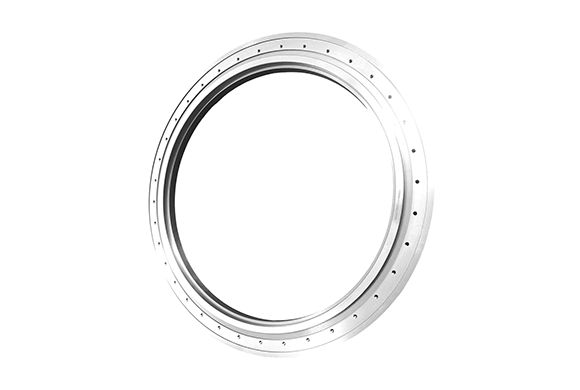

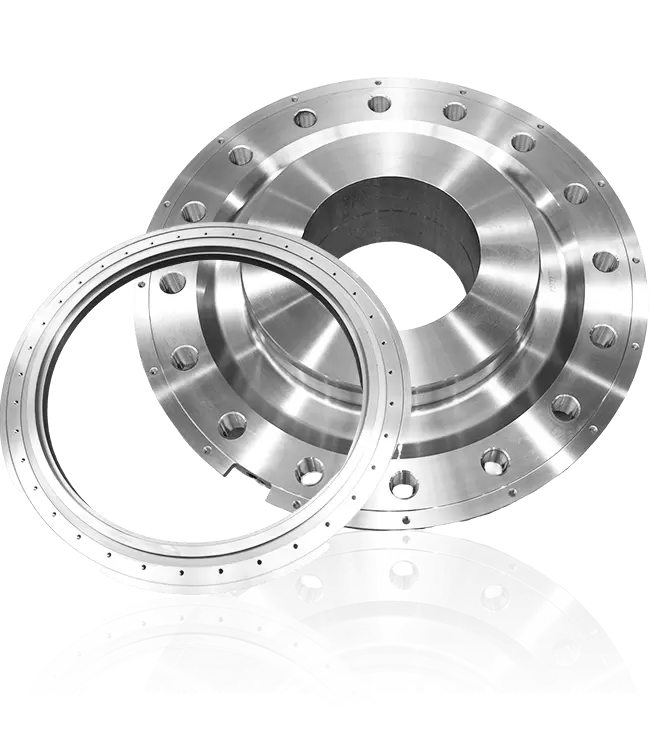

Generator rotors are the heart of any power generation system, and their performance directly impacts the overall efficiency and longevity of the equipment. Recognizing this, we have honed our expertise in customized machining, where each rotor is meticulously crafted to meet the exact specifications and operational demands of your application. From material selection to final assembly, every step in our process is designed to maximize efficiency, minimize wear, and extend service life.

Precision at Every Turn

Our commitment to precision begins with a thorough understanding of your operational environment and performance expectations. Utilizing state-of-the-art CAD/CAM software, we meticulously design each rotor to ensure perfect balance, alignment, and dimensional accuracy. This meticulous approach extends to our machining processes, where advanced CNC milling and turning centers, coupled with rigorous quality control measures, guarantee unparalleled precision and repeatability.

Material Expertise for Superior Durability

Material choice is crucial in the customization of generator rotors. We offer a wide range of materials, including high-strength alloys, stainless steel, and nickel-based superalloys, each tailored to withstand the specific stresses and temperatures encountered in your application. Our material expertise ensures that the rotor you receive not only meets but exceeds your durability and performance expectations.

Balancing Efficiency and Cost

In today's competitive market, balancing efficiency and cost is more critical than ever. Our customized machining approach allows us to optimize the design and manufacturing process for your specific needs, minimizing material waste and reducing lead times without compromising on quality. This not only ensures you receive a rotor that maximizes energy output but also delivers cost savings through enhanced operational efficiency and reduced maintenance requirements.

A Partnership for Long-Term Success

Beyond the manufacturing process, we view our relationship with each client as a partnership for long-term success. Our dedicated engineering team is available to provide ongoing support, from troubleshooting and maintenance advice to the development of custom solutions for evolving operational challenges. We pride ourselves on our ability to adapt and innovate, ensuring your generator rotors remain at the forefront of efficiency and reliability.

Conclusion

As the energy landscape continues to evolve, the demand for customized, high-efficiency generator rotors grows. At our company, we are at the forefront of this trend, leveraging cutting-edge technology and unparalleled expertise to deliver tailored solutions that exceed expectations. Whether you're looking to optimize existing systems or develop next-generation power generation equipment, our customized machining of generator rotors offers the precision, durability, and efficiency tailored to your unique needs.

By choosing us for your generator rotor needs, you're investing in a future of unparalleled performance and reliability. Contact us today to learn more about how our customized machining services can help power your success.