Home / Resources / Blogs / Industry News / Custom Non Metallic Precision CNC Machining Services for High-Performance Parts

Custom Non Metallic Precision CNC Machining Services for High-Performance Parts

In today’s competitive manufacturing and engineering landscape, precision, reliability, and material versatility are essential for producing high-performance components. Non-metallic precision CNC machining has emerged as a critical solution for industries requiring exact tolerances, lightweight components, and corrosion-resistant materials.

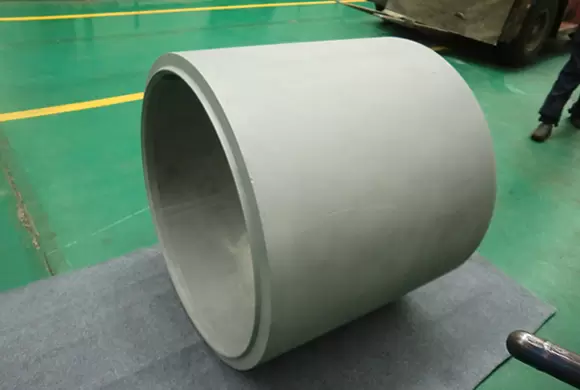

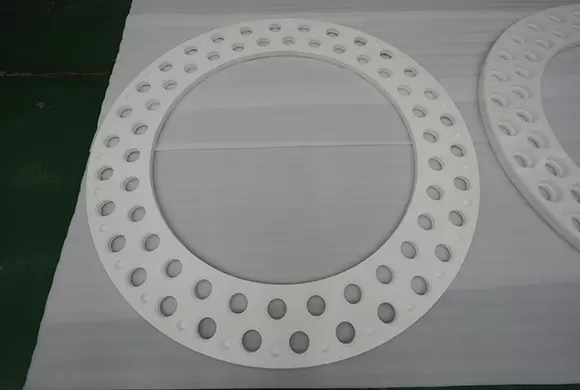

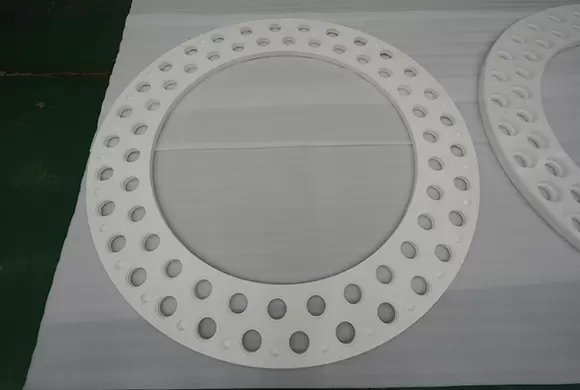

This advanced machining process allows for the fabrication of custom parts from non-metallic materials such as plastics, composites, ceramics, and engineered polymers. By combining computer-controlled machining with specialized tooling, manufacturers can achieve high accuracy, consistent quality, and repeatable results for complex geometries.

What Is Non-Metallic Precision CNC Machining

Non-metallic precision CNC machining involves the use of computer numerical control (CNC) systems to cut, mill, drill, or shape non-metallic materials with high accuracy. Unlike conventional machining, which often relies on manual adjustments, CNC machines use digital instructions to produce components with tight tolerances and complex features.

Key Advantages Include:

High dimensional accuracy and repeatability

Ability to handle intricate shapes and tight tolerances

Reduced material waste due to precise cutting

Compatibility with a wide range of non-metallic materials

Common Non-Metallic Materials for CNC Machining

Composites

Carbon fiber reinforced plastics (CFRP) and glass fiber composites provide high strength-to-weight ratios and excellent thermal stability.

Ceramics

Advanced ceramics offer exceptional hardness, wear resistance, and temperature tolerance, ideal for high-performance applications.

Polymers and Elastomers

Used in seals, gaskets, insulators, and flexible components where non-metallic solutions are necessary.

Selecting the right material is crucial to ensure the component meets performance, durability, and environmental requirements.

Key Features of Non-Metallic Precision CNC Machining

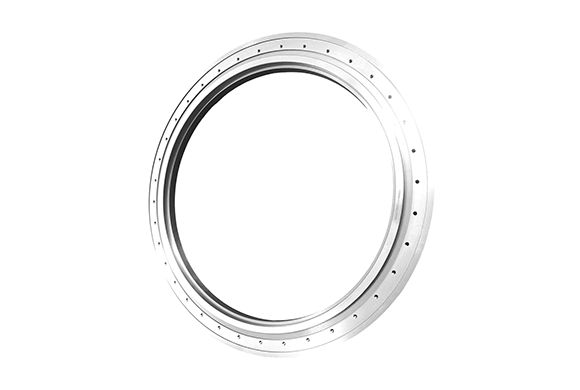

High Accuracy and Tight Tolerances

CNC technology enables machining with tolerances as precise as ±0.01 mm, essential for aerospace, medical, and electronics components.

Complex Geometry Capability

Allows production of intricate parts that are difficult or impossible to achieve with traditional machining.

Rapid Prototyping and Production

Quick transition from design to prototype reduces product development cycles and accelerates time-to-market.

Reduced Material Waste

Precision machining ensures efficient material utilization, lowering production costs.

Consistent Quality

Automated CNC processes guarantee uniformity across multiple components, critical for high-volume manufacturing.

Applications Across Industries

Aerospace and Aviation

Lightweight, high-strength non-metallic components reduce aircraft weight and improve fuel efficiency.

Automotive

Non-metallic machined parts are used in electrical systems, interiors, and specialized high-performance components.

Medical Devices

Machined plastics and ceramics are ideal for surgical instruments, prosthetics, and diagnostic equipment due to their biocompatibility and stability.

Electronics

Non-metallic insulating parts, housings, and connectors benefit from high dimensional accuracy and electrical isolation properties.

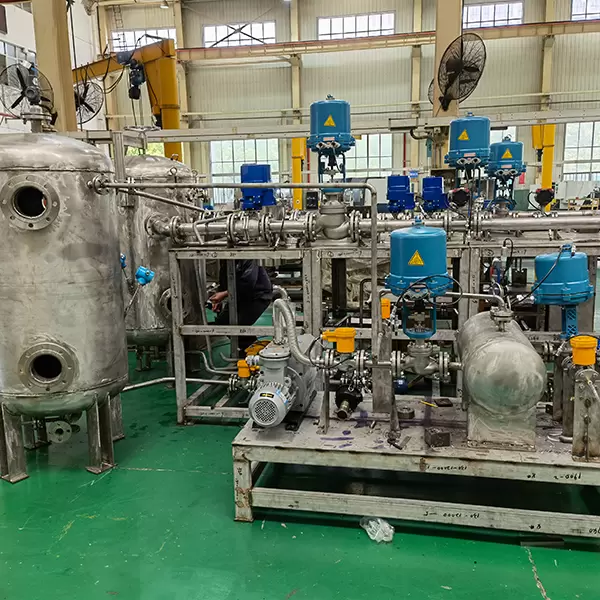

Industrial Equipment

Non-metallic components reduce wear, resist corrosion, and withstand harsh chemical environments in machinery and process equipment.

Advantages Over Traditional Machining

Weight Reduction: Non-metallic components are significantly lighter than metal alternatives, improving system efficiency.

Corrosion and Chemical Resistance: Ideal for harsh environments where metals would degrade.

Noise and Vibration Reduction: Non-metallic parts help reduce operational noise in mechanical assemblies.

Cost Efficiency: Lower material cost, less energy-intensive processing, and reduced maintenance make non-metallic solutions economically attractive.

Quality Assurance and Customization

To ensure high-performance outcomes, reputable CNC machining services implement:

Precision Measurement Systems: Coordinate measuring machines (CMM) and laser inspection for accurate verification.

Customized Design Services: CAD/CAM integration enables clients to receive parts tailored to exact specifications.

Strict Process Control: ISO-certified procedures and continuous monitoring ensure component quality.

Post-Processing Options: Polishing, coating, or finishing services to meet functional and aesthetic requirements.

Conclusion

Non-metallic precision CNC machining is a critical technology for producing high-performance, custom components with exceptional accuracy, durability, and versatility. By combining advanced materials, precision engineering, and CNC automation, manufacturers can meet the evolving demands of aerospace, automotive, medical, and industrial sectors.

Investing in Hongdu custom non-metallic CNC machining services ensures reliable, lightweight, corrosion-resistant, and cost-efficient components, supporting innovation and sustainable manufacturing practices.