Home / Resources / Blogs / Industry News / Ring Forgings Factory | Reliable Forged Steel Rings at Competitive Prices

Ring Forgings Factory | Reliable Forged Steel Rings at Competitive Prices

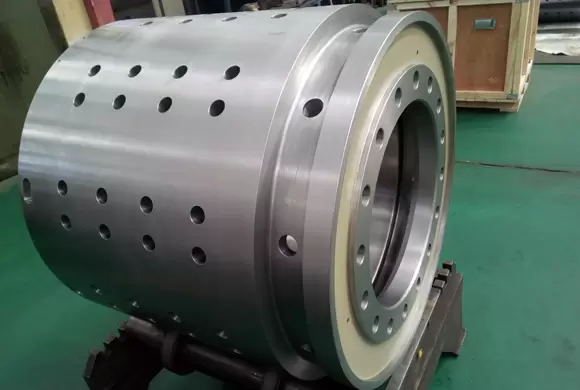

In modern industrial manufacturing, ring forgings play a vital role in ensuring the strength, durability, and reliability of critical mechanical components. From aerospace to oil and gas, automotive, and heavy machinery industries, forged steel rings are the foundation of equipment that demands both precision and performance.

Jiangxi Hongdu Precision Machinery, a professional ring forgings factory in China, specializes in producing high-quality forged steel rings that meet global standards. With advanced forging technology, experienced engineers, and strict quality control, Jiangxi Hongdu delivers reliable forged components at competitive prices to customers around the world.

What Are Ring Forgings

Ring forgings are seamless circular components produced through a controlled forging process. This involves heating a metal billet and shaping it under compressive forces to achieve a uniform grain structure and superior mechanical properties.

Depending on the application, Jiangxi Hongdu manufactures ring forgings in various materials, including:

Carbon Steel – Excellent for general engineering applications.

Alloy Steel – Ideal for high-stress environments.

Stainless Steel – Provides superior corrosion resistance.

Nickel and Titanium Alloys – Suitable for aerospace and high-temperature uses.

These forged rings are widely used in bearings, flanges, gears, pressure vessels, turbines, and transmission systems, where strength, toughness, and dimensional accuracy are critical.

Advantages of Forged Steel Rings from Jiangxi Hongdu

1. Seamless Strength and Superior Durability

Unlike cast rings, forged rings have a continuous grain flow that follows the shape of the component. This significantly improves tensile strength, fatigue resistance, and impact toughness, ensuring long service life even under extreme operating conditions.

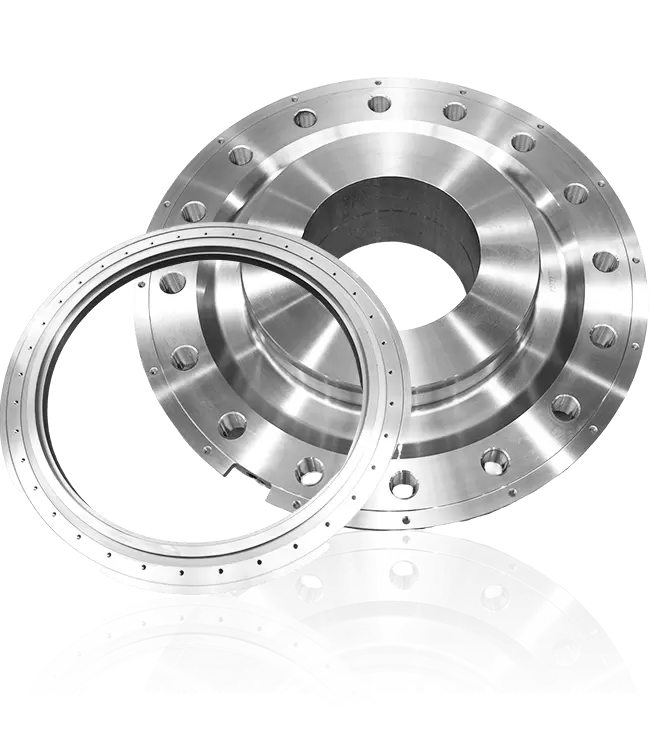

2. High Precision and Dimensional Accuracy

Jiangxi Hongdu Precision Machinery utilizes computer-controlled forging presses and CNC machining to achieve precise tolerances and consistent geometry. Every forged ring undergoes rigorous inspection to meet exact specifications for diameter, thickness, and roundness.

3. Wide Range of Sizes and Materials

With a flexible production system, Jiangxi Hongdu can produce small precision rings weighing just a few kilograms as well as large industrial forgings exceeding several tons. Custom material grades and heat treatments are available to meet the specific mechanical requirements of each project.

4. Heat Treatment and Machining Expertise

To achieve optimal mechanical properties, Jiangxi Hongdu performs controlled heat treatment processes such as quenching, tempering, and normalizing. Combined with CNC finishing and surface machining, the result is a forged ring that offers both strength and surface integrity for high-performance use.

5. Cost-Effective Global Supply

As a factory-direct manufacturer, Jiangxi Hongdu provides competitive pricing without compromising quality. Efficient production lines, optimized material usage, and bulk-order capabilities enable fast turnaround times and consistent cost savings for clients worldwide.

Applications of Ring Forgings

Jiangxi Hongdu Precision Machinery’s ring forgings are designed to serve a wide range of industries, including:

Aerospace: Aircraft engine components, jet turbines, and landing gear rings.

Oil & Gas: Flanges, connectors, and pressure vessel parts.

Automotive: Gears, bearings, and transmission systems.

Energy & Power Generation: Turbine rings and generator shafts.

Construction & Heavy Equipment: Rotating joints, couplings, and support structures.

Each forged ring is engineered to withstand high pressure, temperature, and load conditions, providing unmatched reliability in critical industrial applications.

Commitment to Quality and Sustainability

At Jiangxi Hongdu, forging excellence goes hand in hand with environmental responsibility. The company follows sustainable manufacturing practices, including:

Energy-efficient furnaces and recycling of scrap metals.

Eco-friendly surface finishing and waste management systems.

Continuous improvement in process optimization to minimize material waste.

By integrating innovation, quality control, and green manufacturing, Jiangxi Hongdu ensures that every forged ring not only performs flawlessly but also contributes to a sustainable industrial future.

Conclusion

When it comes to high-quality ring forgings, Jiangxi Hongdu Precision Machinery is a trusted global partner offering precision-engineered forged steel rings that combine strength, consistency, and affordability.

With years of manufacturing expertise and a dedication to customer satisfaction, Jiangxi Hongdu continues to deliver world-class forging solutions for the most demanding applications. Whether you need standard sizes or custom-designed ring forgings, Jiangxi Hongdu ensures performance, reliability, and value in every piece.

For more product details, please visit:

Ring Forgings – Jiangxi Hongdu Precision Machinery