Home / Resources / Blogs / Industry News / Advanced Non Metallic Parts Processing Methods and Applications

Advanced Non Metallic Parts Processing Methods and Applications

In the realm of manufacturing, the evolution of processing methods for non-metallic parts has been pivotal in enhancing product performance, reducing costs, and enabling innovative designs. Non-metallic materials, including plastics, ceramics, composites, and glasses, offer unique properties such as lightweightness, corrosion resistance, and thermal insulation, making them indispensable in various industries.

1. Injection Molding: The Workhorse of Plastics Processing

Process Overview

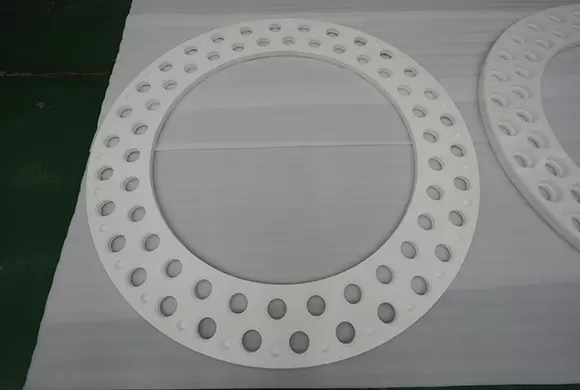

Injection molding is a widely used manufacturing process for producing plastic parts in high volumes. It involves melting plastic material, injecting it into a mold cavity under pressure, and then cooling to solidify the part. This method offers precision, repeatability, and cost-effectiveness, especially for complex geometries.

Advancements

Recent advancements in injection molding include multi-component molding, which allows for the combination of different materials in a single mold, and in-mold labeling, which integrates graphics or text directly into the part. These innovations enhance aesthetic appeal and functionality.

Applications

Injection molded parts are ubiquitous in automotive components, consumer electronics, packaging, and medical devices. Their versatility makes them suitable for a range of applications requiring durability, precision, and cost-efficiency.

2. Additive Manufacturing: Revolutionizing Customization and Complexity

Technology Overview

Additive manufacturing, or 3D printing, is transforming non-metallic part production by enabling the creation of complex geometries and personalized designs. Processes like fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) are commonly used with plastics, composites, and ceramics.

Innovations

Advancements in materials, such as high-performance polymers and biocompatible ceramics, expand the range of applications. Multi-material printing and hybrid systems that combine additive and subtractive processes further enhance capabilities.

Applications

Additive manufacturing is revolutionizing industries such as aerospace, where lightweight, strong components are crucial, and healthcare, where patient-specific implants and prosthetics are becoming standard.

3. Ceramic Forming Techniques: Harnessing High-Performance Materials

Traditional and Advanced Methods

Ceramic parts are typically produced through processes like slip casting, dry pressing, and sintering. Advanced techniques include hot isostatic pressing (HIP) for enhanced density and mechanical properties, and gelcasting for intricate shapes.

Material Innovations

The development of advanced ceramic materials, such as zirconia and alumina composites, offers improved wear resistance, thermal stability, and corrosion resistance.

Applications

Ceramic parts find applications in cutting tools, engine components, and medical implants due to their hardness, durability, and biocompatibility. They are also crucial in electronics for their insulating properties.

4. Composite Manufacturing: Balancing Strength and Weight

Processing Techniques

Composite materials, consisting of reinforcement fibers embedded in a resin matrix, are processed through methods like autoclave curing, resin transfer molding (RTM), and vacuum-assisted resin transfer molding (VARTM).

Technological Advancements

Innovations in automation, such as robotic layup and tape laying, improve production efficiency and part quality. Out-of-autoclave curing techniques reduce costs and enable larger-scale manufacturing.

Applications

Composites are pivotal in aerospace for lightweight structures, automotive for fuel efficiency, and wind energy for blade strength and durability. Their combination of high strength and low weight makes them ideal for performance-critical applications.

5. Glass Forming and Machining: Precision and Aesthetics

Forming Techniques

Glass parts are formed through processes like blowing, pressing, and drawing. Advanced techniques such as precision glass molding (PGM) and fused deposition modeling (glass version) enable high-precision parts with complex geometries.

Machining and Finishing

Machining glass, though challenging due to its brittleness, is facilitated by advanced diamond tooling and ultra-precision CNC machines. Chemical etching and polishing techniques enhance surface finish.

Applications

Glass components are essential in optics, electronics, and consumer products for their transparency, hardness, and aesthetic appeal. Innovations in glass forming and machining are driving advancements in displays, sensors, and wearable technology.

Conclusion

The advanced processing methods for non-metallic parts are driving significant strides in various industries. From injection molding and additive manufacturing to ceramic forming and composite manufacturing, these techniques offer unprecedented precision, versatility, and cost-effectiveness. As material science continues to evolve, the potential applications for non-metallic parts will only expand, further solidifying their role in modern manufacturing.