Home / Resources / Blogs / Industry News / How to Choose the Best Mechanical Parts for Your Car or Motorcycle

How to Choose the Best Mechanical Parts for Your Car or Motorcycle

1. Regular inspection of vehicle mechanical parts ensures safety and reliability for both cars and motorcycles.

2. High-quality components from trusted manufacturers like Jiangxi Hongdu Preciosion Machinery reduce risks and improve road safety.

3. Choosing the right parts boosts vehicle performance and supports the safety of vehicles.

4. Industry studies show that inspection and predictive maintenance with premium materials extend vehicle longevity and minimize failures.

5. The Automobile and Motorcycle Series from Jiangxi Hongdu Preciosion Machinery stands out in Automobile and Motorcycle mechanical parts manufacturing, offering advanced solutions for inspection and motorcycle applications.

Inspection of motorcycle components protects safety. Inspection of vehicle systems maximizes safety. Inspection of mechanical assemblies supports road safety. Inspection of motorcycle frames improves safety. Inspection of vehicle engines increases safety. Inspection of motorcycle brakes enhances safety. Inspection of vehicle transmissions maintains safety. Inspection of motorcycle suspensions preserves safety. Inspection of vehicle mold parts ensures safety. Inspection of motorcycle accessories strengthens safety.

Key Takeaways

· Regular inspection of vehicle and motorcycle parts keeps your ride safe and reliable by catching problems early and preventing breakdowns.

· Choose high-quality parts from trusted brands like Jiangxi Hongdu Precision Machinery to improve performance, ensure compatibility, and extend your vehicle's life.

· Seek expert advice and carefully compare prices, warranties, and part quality to make smart, confident decisions that protect your investment and safety.

Identify Vehicle Needs

Owner’s Manual

A thorough periodic vehicle inspection starts with the owner's manual. This document provides essential details for every vehicle, including motorcycle models. Owners should verify that part numbers match the vehicle’s specifications. Mismatched parts can cause mechanical issues and compromise safety. Inspection of mounting points and connection interfaces ensures reliable installation. During periodic vehicle inspection, checking for cracks, stripped threads, or bent tabs prevents future failures. Moving components such as bearings and springs require careful inspection for smooth operation. Using new gaskets and seals during installation helps maintain emissions standards and prevents leaks. For complex components like ECUs or transmission parts, professional installation is recommended to ensure compliance with emissions regulations and safety standards. Documentation of a part’s history, including mileage and previous use, supports accurate assessment during vehicle periodic inspection.

Tip: Installation instructions and photos in the manual assist with remote compatibility checks, especially for motorcycle owners customizing their vehicles.

Purpose: Repair or Upgrade

The purpose behind selecting motorcycle parts—whether for repair or upgrade—directly influences the inspection process. Different engines demand unique components and inspection routines. The table below highlights how engine type and riding style affect motorcycle part selection and inspection needs:

Engine Type | Riding Style | Inspection Focus |

Single Cylinder | Commuter, Beginner | Chain, cooling, emissions |

Parallel Twin | Standard, Cruiser | Suspension, emissions |

V-Twin | Cruiser, Adventure | Torque, exhaust gas emissions test |

Flat Twin (Boxer) | Touring, Adventure | Stability, emissions |

Inline Four | Sport, Touring | High-rev, emissions |

Motorcycle inspection routines must adapt to environmental exposure. Chains, for example, require replacement every 20,000–30,000 kilometers, but harsh conditions accelerate wear. Regular cleaning, lubrication, and tightening extend the life of motorcycle components. Visible signs like rust, elongation, or slippage signal immediate replacement. For optimal performance, replace the entire drive train after two chain replacements. These maintenance principles apply to all motorcycle parts exposed to the elements.

A comprehensive periodic vehicle inspection includes emissions checks, exhaust gas emissions test, and routine inspection of all motorcycle components. Consistent vehicle inspection and timely maintenance prevent mechanical issues and ensure safe, reliable operation.

Evaluate Parts & Manufacturers

OEM vs. Aftermarket

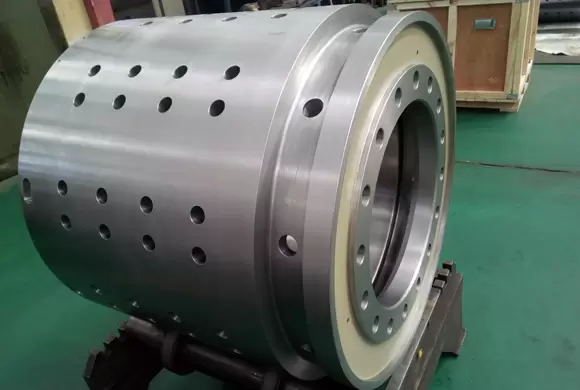

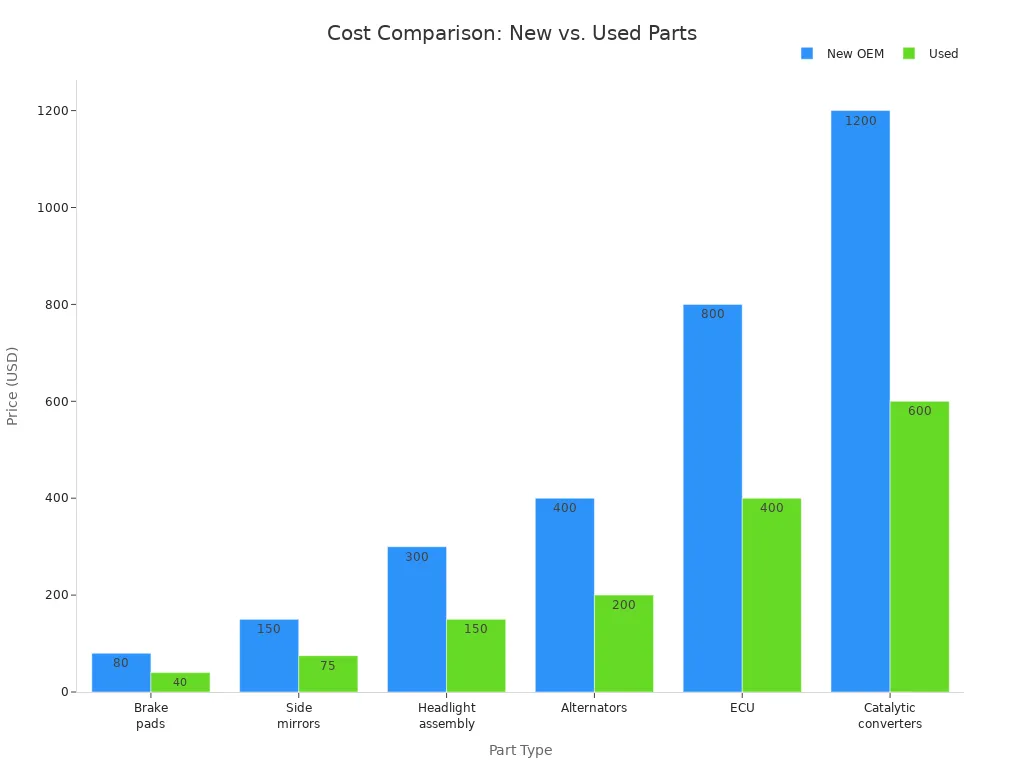

Automobile and motorcycle mechanical parts manufacturing presents buyers with several options. OEM (Original Equipment Manufacturer) parts offer the highest level of quality and reliability. These components meet strict safety standards and align perfectly with vehicle specifications. Most consumers prefer OEM for engine components, with 58% choosing them over aftermarket alternatives. Aftermarket parts, produced independently, provide cost savings but may vary in quality and reliability. Inspection of aftermarket products is essential to ensure compatibility and safety. Refurbished and rebuilt parts balance affordability and reliability, especially for older vehicles or temporary repairs. The table below compares quality, cost, and reliability across different part types:

Part Type / Condition | Quality Description | Cost Comparison (vs. New OEM) | Reliability Notes |

Like New | Minimal wear, functions almost like new | Close to new OEM price | High reliability, often from minor accident vehicles |

Slightly Used | Some use, excellent working condition | About 50% less than new OEM | Good balance of cost savings and reliability |

Used - Good Condition | Moderate wear, fully functional | Approximately 50% less than new OEM | Suitable for older vehicles or less critical use |

Used - Fair Condition | Noticeable wear, still functional | Significantly cheaper than new OEM | Best for budget or temporary repairs |

Reconditioned (Refurbished) | Professionally restored to good working condition | Around 50% less than new OEM | Offers best value combining affordability and reliability |

Inspection of each part for damage, wear, and compatibility remains critical. Professional installation, especially for complex components such as ECU or transmission, ensures safety and optimal performance. Using new seals and hardware during installation extends the lifespan of mechanical systems.

Trusted Brands

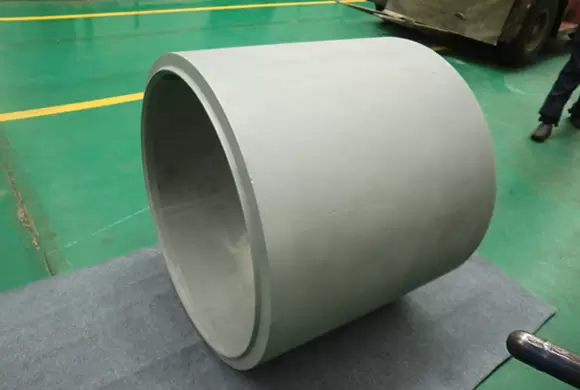

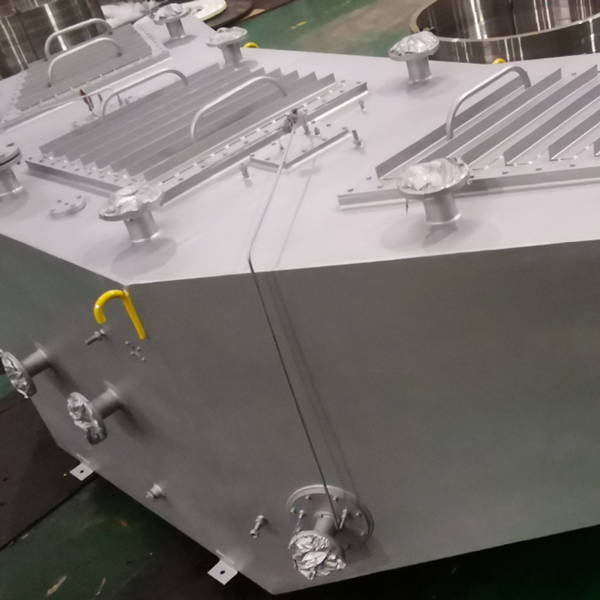

Selecting trusted brands in automobile and motorcycle mechanical parts manufacturing guarantees consistent quality and safety. Jiangxi Hongdu Precision Machinery Co., Ltd. stands out with its Automobile and Motorcycle Series. The company specializes in advanced CNC machining, producing mold parts and steel components with intricate designs. Their quick service, including 24-hour quotations, supports efficient project planning. Inspection of brand reputation, customer reviews, and warranty policies helps buyers make informed decisions. Trusted brands often provide better tuning options, durability, and alignment with vehicle requirements.

Note: Choosing reputable manufacturers reduces the risk of premature wear and supports road safety.

Quality & Compatibility

Quality and compatibility play a central role in automobile and motorcycle mechanical parts manufacturing. Inspection of certifications such as ISO 9001 and IATF 16949 confirms adherence to industry standards. Buyers should request material test reports and compliance documentation to verify raw material quality. Capability audits and sample testing further ensure production quality. High-quality materials, such as aluminum alloys, offer strength, flexibility, and corrosion resistance. These properties extend component life, improve fuel efficiency, and enhance passenger comfort. Inspection of brake pads, rotors, and tires for material quality prevents premature failure and supports safety. Alignment of parts with vehicle specifications ensures reliable installation and operation.

· Key certifications to consider:

· ISO 9001 (quality management)

· IATF 16949 (automotive industry standard)

· Material test reports

· Compliance documentation

· Material quality impacts:

· Poor-quality brake pads and rotors wear faster and reduce lifespan.

· Tires made from low-grade materials fail prematurely.

· Aluminum alloys provide corrosion resistance and vibration dampening.

· High-quality materials improve performance and extend service life.

Inspection of each component before installation supports safety and long-term reliability.

Motorcycle Suspension

Motorcycle suspension systems require careful evaluation during automobile and motorcycle mechanical parts manufacturing. Suspension components must fit the bike’s frame, mounting points, and geometry. Inspection of compatibility, travel length, and damping adjustability ensures optimal alignment and safety. Riders should match suspension travel to their riding style and terrain. Damping adjustability allows fine-tuning for rider weight and terrain demands. Trusted brands offer better performance, durability, and tuning options. The table below summarizes key factors for selecting motorcycle suspension:

Factor | Explanation |

Compatibility | Suspension components must fit the bike's frame design, mounting points, and geometry. |

Suspension Type | Choose between front, rear, or full suspension based on intended use and frame design. |

Suspension Travel | Match travel length (e.g., 100-170mm) to riding style and terrain demands. |

Damping Adjustability | Ability to fine-tune rebound, compression, and preload to suit rider weight and terrain. |

Rider Characteristics | Consider rider weight and riding style to select appropriate suspension stiffness and tuning. |

Terrain Type | Select suspension suited for terrain, e.g., more travel and damping for rough or steep trails. |

Budget and Value | Balance cost with performance needs and maintenance comfort. |

Maintenance Needs | Different suspension types require varying levels of upkeep; choose based on maintenance ability. |

Component Integration | Ensure suspension works well with brakes, drivetrain, and axle standards. |

Brand Reputation | Trusted brands often provide better performance, tuning options, and durability. |

Inspection of suspension systems, including brake and wheel alignment check, supports safety and enhances motorcycle handling. Proper alignment of suspension components with brakes and drivetrain ensures smooth operation and road safety. Regular inspection and maintenance of motorcycle suspension systems prevent damage and extend service life.

Compare & Buy

Price & Warranty

Buyers should compare prices, warranties, and return policies from trusted suppliers before purchasing any vehicle or motorcycle part. The average price range for high-quality mechanical parts varies based on type and material. For example, precision CNC machined parts for a motorcycle or car can cost between $0.05 and $1.80 per piece, while commonly sold auto parts range from $7.89 to $16.02. Premium options may reach $32.28. The table below summarizes these price ranges:

Price Range (USD) | Description | Notes |

$0.05 - $1.80 | Precision CNC machined parts | Price per piece, minimum order varies |

$7.89 - $16.02 | Popular auto and motorcycle parts | Weighted mean price $8.69 |

$24.15 - $32.28 | Premium and niche mechanical parts | Higher quality, less common |

Warranty coverage plays a vital role in protecting your investment and ensuring safety. Motorcycle extended warranties often cover engine, transmission, electrical, and suspension systems. Certified Pre-Owned vehicle options may include additional inspection and warranty layers. Buyers should evaluate coverage, costs, and ownership timelines to match their needs.

Where to Buy

Selecting the right platform for purchasing vehicle and motorcycle parts impacts both convenience and safety. Webike Japan stands out as a reputable online source, offering over 800,000 motorcycle items and a user-friendly system for matching parts to specific models. The platform provides exclusive deals, genuine OEM parts, and aftermarket components from premium brands. Local authorized retailers also offer a wide range of new and pre-owned vehicles and parts, professional installation, and comprehensive service departments. Friendly staff guide customers through the buying process, ensuring proper inspection and warranty coverage. Competitive pricing and financing options further support buyers seeking value and road safety.

Expert Advice

Expert advice remains essential for anyone buying a motorcycle or vehicle part, especially first-time buyers. Mechanics can identify issues that novices might miss during inspection. A thorough visual inspection should include checking for crash signs, tire condition, chain and sprocket wear, and leaks around seals. Reviewing maintenance records and vehicle history reports helps verify ownership and past repairs. Mechanical assessments, such as starting the motorcycle cold and listening for unusual engine sounds, ensure reliability. Testing all electronics, including lights and instruments, confirms proper function. Buyers should avoid common mistakes like skipping inspections, rushing decisions, or overlooking documentation. Consulting forums, mechanics, and experienced riders can provide valuable insights into motorcycle insurance, safety, and total cost of ownership. Careful evaluation and patience help buyers make informed decisions and maintain road safety.

A thorough inspection of every vehicle ensures safety and reliability. Regular inspection of motorcycle components prevents failures. Each vehicle benefits from detailed inspection routines. Motorcycle owners should prioritize inspection for optimal performance. Trusted manufacturers like Jiangxi Hongdu Precision Machinery Co., Ltd. support vehicle longevity. Inspection, value, and quality drive smart vehicle and motorcycle choices.

FAQ

What is the importance of regular vehicle periodic inspection?

Regular vehicle periodic inspection helps identify issues early. Inspection ensures the vehicle remains safe. Inspection also maintains performance. Vehicle periodic inspection supports long-term reliability. Inspection prevents unexpected breakdowns.

How often should a vehicle undergo inspection?

A vehicle should receive inspection every six months. Vehicle periodic inspection schedules may vary. Inspection frequency depends on vehicle age. Inspection also depends on usage. Vehicle periodic inspection ensures ongoing safety.

What areas does a typical vehicle periodic inspection cover?

Vehicle periodic inspection covers brakes, suspension, and lights. Inspection includes engine components. Inspection checks tires and emissions. Vehicle periodic inspection also reviews safety systems. Inspection ensures all vehicle systems function properly.

Tip: Always keep records of each vehicle periodic inspection. Inspection history helps track maintenance and supports resale value.