Home / Resources / Blogs / Industry News / Exploration of Advanced Manufacturing Processes and Technologies for Generator Rotor

Exploration of Advanced Manufacturing Processes and Technologies for Generator Rotor

In the realm of power generation, the generator rotor plays a pivotal role, converting mechanical energy into electrical energy with utmost efficiency and reliability. With the continuous advancement in technology and the increasing demand for clean and efficient energy, the design and manufacturing of generator rotors have become more complex and demanding.

Design Overview and Challenges

Generator rotors are intricate components, characterized by their large size, significant weight, and intricate geometry. Key Design Features and Challenges:

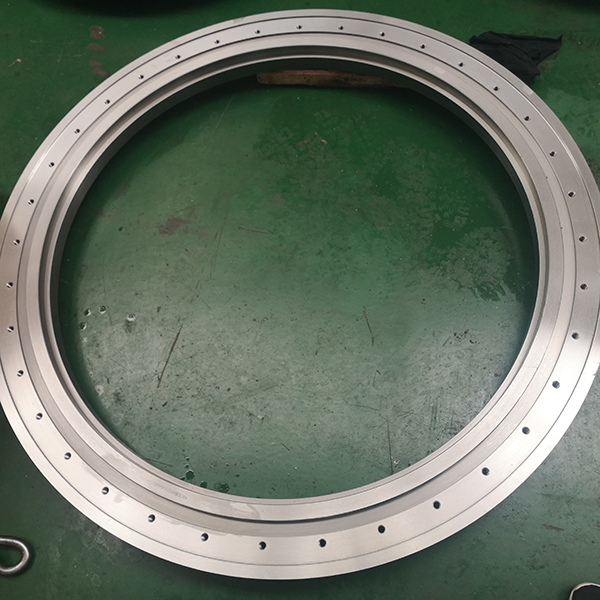

Large Part Size and Weight: Typically, a generator rotor part weighs over one ton, necessitating robust manufacturing equipment and handling procedures.

Precision Requirements: The minimum size tolerance required is 0.025mm, with a position tolerance of 0.03mm. Meeting these extremely high precision standards is crucial for ensuring the rotor's operational efficiency and longevity.

Complexity in Manufacturing: Due to the part's size and precision demands, processing difficulty is significant. Traditional manufacturing methods often struggle to achieve the required accuracy and surface finish.

Advanced Manufacturing Processes

To address these challenges, several advanced manufacturing processes and technologies have been developed and implemented.

1. Precision Machining

Precision machining is fundamental in the fabrication of generator rotors. Utilizing state-of-the-art Computer Numerical Control (CNC) machines, manufacturers can achieve the tight tolerances demanded by modern rotor designs. Techniques such as high-speed milling and five-axis machining enable intricate features to be milled with exceptional accuracy and surface quality.

Five-Axis Machining: This technology allows for complex shapes to be machined in a single setup, reducing handling and setup errors, and thereby enhancing precision.

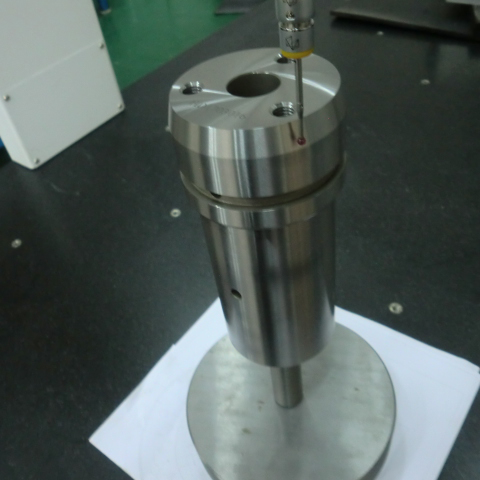

In-Process Measurement: Integration of in-process measurement systems ensures that each stage of machining meets the specified tolerances, minimizing the need for post-machining corrections.

2. Additive Manufacturing (3D Printing)

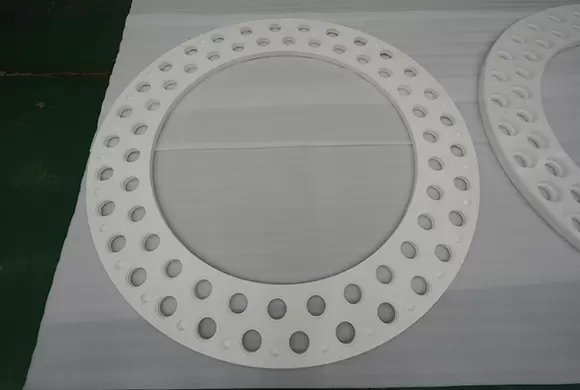

Additive manufacturing, particularly metal 3D printing, offers unique advantages for generator rotor production. By building up layers of material to form the desired shape, AM can produce intricate internal cooling channels and other complex features that are difficult or impossible to achieve with traditional methods.

Complex Geometry: AM enables the creation of intricate cooling passages within the rotor, optimizing thermal management and enhancing efficiency.

Material Efficiency: Reduced material waste and the ability to use high-performance alloys contribute to lighter, stronger rotors.

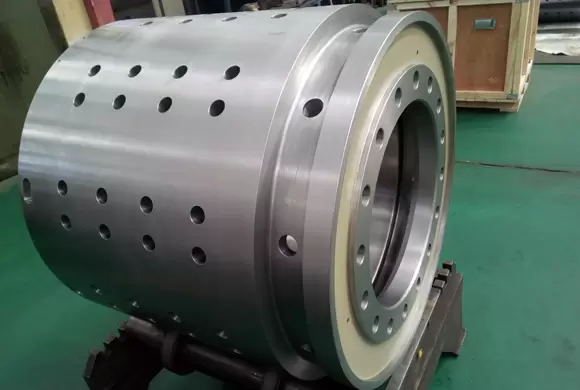

3. Electron Beam Welding (EBW)

Electron beam welding is a critical process in rotor manufacturing, particularly for joining large sections. EBW provides a high-energy, focused beam of electrons that melts the material at the joint, resulting in narrow, deep welds with minimal heat-affected zones.

High Precision: EBW ensures precise control over the welding process, minimizing distortion and maintaining tight tolerances.

Defect-Free Welds: The process produces welds with very low porosity and crack sensitivity, enhancing the rotor's structural integrity.

Enhancements in Structural Performance and Assembly Efficiency

The adoption of these advanced manufacturing processes has led to significant improvements in generator rotor design and production.

Improved Structural Performance

Through the use of high-performance materials and precise manufacturing techniques, the overall structural performance of generator rotors has been enhanced. Features such as optimized cooling channels and stress-relief designs contribute to improved thermal efficiency and mechanical strength.

Reduced Assembly Time

Advanced manufacturing processes, particularly additive manufacturing and precision machining, have streamlined the rotor assembly process. Components that were previously assembled using multiple pieces and fasteners can now be manufactured as a single integral part, greatly saving assembly time and reducing the potential for assembly errors.

Integral Design: Additive manufacturing allows for the creation of complex geometries as a single piece, eliminating the need for multiple assemblies.

Automated Assembly Lines: Integration of automation and robotics in assembly lines further reduces manual handling and enhances productivity.

Meeting Precision Requirements

The combination of precision machining, in-process measurement, and advanced welding techniques ensures that generator rotors meet the stringent precision requirements. The minimum size tolerance of 0.025mm and position tolerance of 0.03mm are consistently achieved, guaranteeing the rotor's operational efficiency and reliability.

Conclusion

The exploration of advanced manufacturing processes and technologies for generator rotors has resulted in significant advancements in design, production efficiency, and structural performance. By leveraging precision machining, additive manufacturing, and electron beam welding, manufacturers can produce rotors that meet the most demanding specifications while reducing assembly time and costs. As the energy sector continues to evolve, these advanced manufacturing techniques will play a crucial role in developing more efficient, reliable, and sustainable generator rotors.