Home / Resources / Blogs / Industry News / Application of Intelligent Manufacturing in the Processing of Mining Machinery Processing Parts

Application of Intelligent Manufacturing in the Processing of Mining Machinery Processing Parts

The mining industry relies heavily on high-performance equipment, and mining machinery processing parts play a vital role in ensuring reliability, efficiency, and safety. Traditional manufacturing processes often struggle to meet the modern demand for precision, speed, and customization. Intelligent manufacturing, integrating advanced automation, data analytics, and digital technologies, offers a revolutionary approach to producing mining machinery processing parts.

1. Introduction

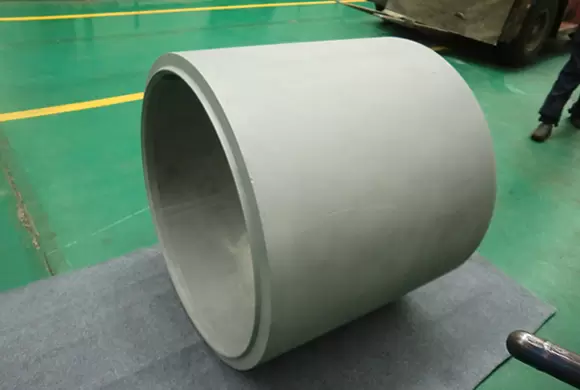

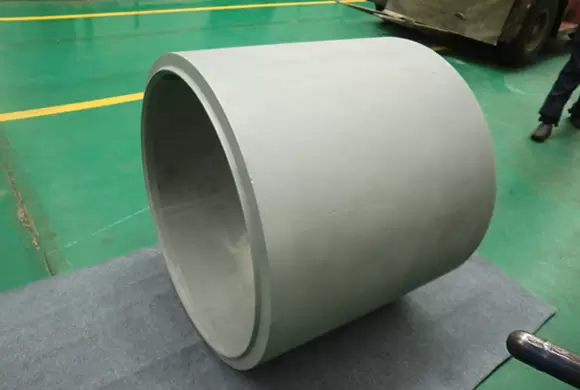

Mining machinery processing parts—such as gears, shafts, hydraulic components, wear-resistant liners, and drive elements—are the backbone of heavy-duty mining equipment. These components must endure extreme operating environments, including abrasive materials, high impact forces, and temperature fluctuations. Precision and durability are not optional; they are critical requirements.

In recent years, the rise of Intelligent Manufacturing has transformed the way mining machinery processing parts are designed, produced, and delivered. By incorporating advanced technologies like CNC machining, AI-based quality inspection, digital twin modeling, and IoT-enabled monitoring, manufacturers can significantly enhance production efficiency and product quality. This transformation is not only about automation but also about smarter, data-driven decision-making throughout the manufacturing process.

2. Key Technologies in Intelligent Manufacturing for Mining Machinery Parts

2.1 CNC Machining with Automation

Computer Numerical Control (CNC) machining ensures parts are manufactured with extreme precision, often within tolerances of micrometers. When integrated with robotic automation, CNC systems can operate around the clock, producing mining machinery processing parts consistently without human error. This combination boosts productivity while reducing downtime.

2.2 Digital Twin and Simulation

A digital twin is a virtual representation of a physical product or process. In the manufacturing of mining machinery processing parts, engineers use digital twins to simulate production workflows, optimize part designs, and predict potential failures before actual production begins. This reduces costly trial-and-error and accelerates time-to-market.

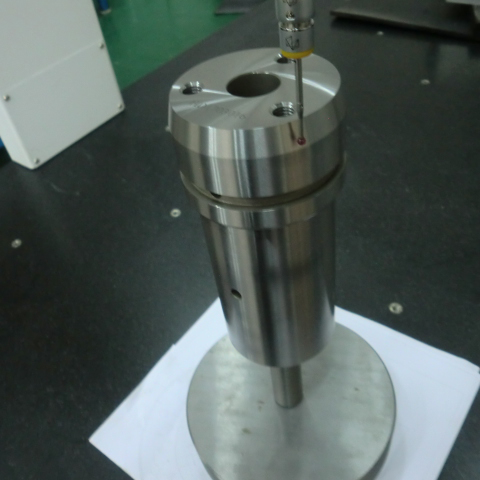

2.3 AI-Powered Quality Control

Artificial intelligence, combined with high-resolution imaging systems, enables real-time defect detection. Surface imperfections, dimensional deviations, and assembly misalignments can be identified instantly, ensuring that only parts meeting strict quality standards leave the production line.

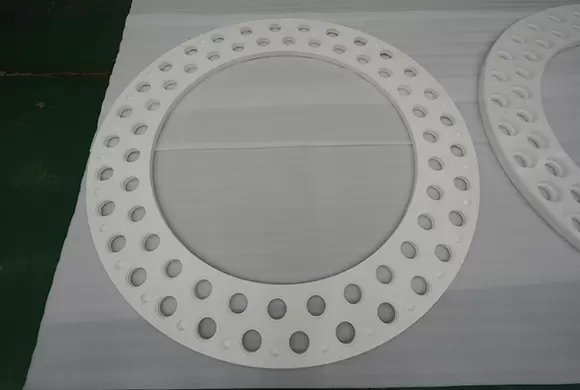

2.4 Additive Manufacturing for Custom Parts

Additive manufacturing (3D printing) allows for rapid prototyping and the creation of complex geometries that traditional machining cannot easily produce. For specialized mining machinery processing parts—such as lightweight brackets or optimized wear-resistant components—this technology provides unmatched flexibility.

2.5 IoT-Enabled Production Monitoring

The Internet of Things (IoT) allows machines, sensors, and systems to communicate in real time. In a smart factory setting, IoT devices track production metrics, monitor machine health, and predict maintenance needs, reducing unexpected equipment downtime.

3. Benefits of Intelligent Manufacturing in Mining Machinery Parts

Improved Precision and Consistency – Automated processes ensure each part meets exact design specifications, enhancing equipment reliability.

Shorter Lead Times – Real-time data analysis and automation reduce delays, enabling faster delivery to customers.

Cost Reduction – Optimized workflows minimize material waste, lower labor costs, and improve energy efficiency.

Enhanced Customization – Manufacturers can produce small batches of customized parts without sacrificing efficiency.

Sustainability – Intelligent manufacturing aligns with eco-friendly practices by reducing scrap material and optimizing resource usage.

4. Future Outlook

As mining operations become more automated and data-driven, the demand for high-quality mining machinery processing parts will continue to grow. Future developments in intelligent manufacturing—such as advanced robotics, machine learning optimization, and fully autonomous production lines—will further enhance manufacturing capabilities, enabling even greater precision, efficiency, and customization.

5. Conclusion

The integration of intelligent manufacturing in the processing of mining machinery parts is no longer a trend—it is a necessity for manufacturers aiming to compete in the modern industrial landscape. By embracing automation, digital technologies, and real-time data analytics, companies can produce mining machinery processing parts that meet the highest standards of precision, durability, and performance, while also reducing costs and lead times.

In an industry where downtime can cost millions, intelligent manufacturing offers the tools to ensure reliability, efficiency, and long-term success.