Home / Resources / Blogs / Industry News / A Complete Guide to ASM Series Customized Processing in China

A Complete Guide to ASM Series Customized Processing in China

There is strong demand for ASM series customized processing in China, with the ASM Series standing out for its precision-engineered, load-bearing welding assembly components. Jiangxi Hongdu Precision Machinery specializes in delivering advanced equipment and quality service, ensuring you receive custom solutions tailored to your industrial requirements. Trust Jiangxi Hongdu Precision Machinery for ASM Series products that meet the highest standards in ASM series customized processing in China.

Key Takeaways

· Choose ASM Series components customized to your exact needs by selecting the right product type, material grade, and features for strength and durability.

· Follow a clear process from consultation to delivery with Jiangxi Hongdu Precision Machinery to ensure quality, timely production, and responsive support.

· Communicate clearly, approve samples early, and request regular updates to avoid mistakes and guarantee your ASM Series components meet high standards.

Customization Options

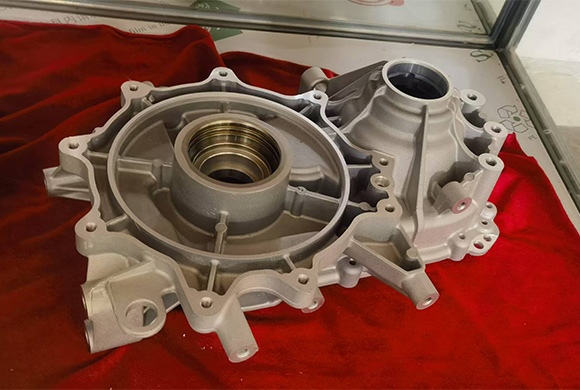

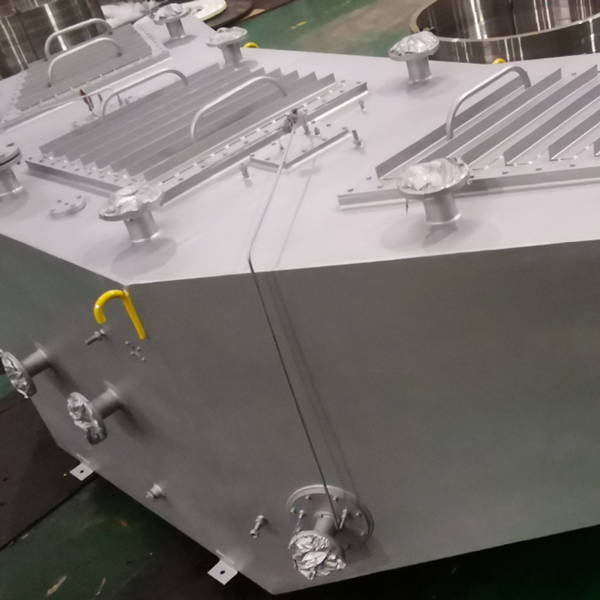

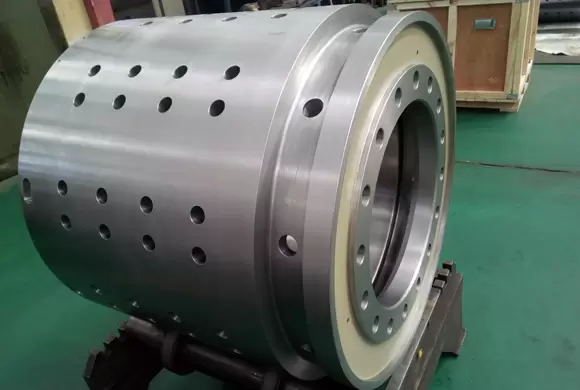

Jiangxi Hongdu Precision Machinery Co., Ltd. offers the ASM Series as structural load-bearing welding assembly components. You can select from a wide range of product types, each designed for demanding industrial environments. The ASM Series supports applications where strength and durability matter most.

Product Types

You have access to several ASM Series product types. These include brackets, frames, supports, and custom assemblies. Each type serves a specific function in heavy machinery, construction, or manufacturing. You can request products tailored to your project’s load requirements and installation needs.

Custom Features

Customization plays a key role in ASM series customized processing in China. You can choose features such as:

· Size and dimensions

· Material grade

· Functional enhancements

· Branding and labeling

· Hardware or software integration

· Interface compatibility

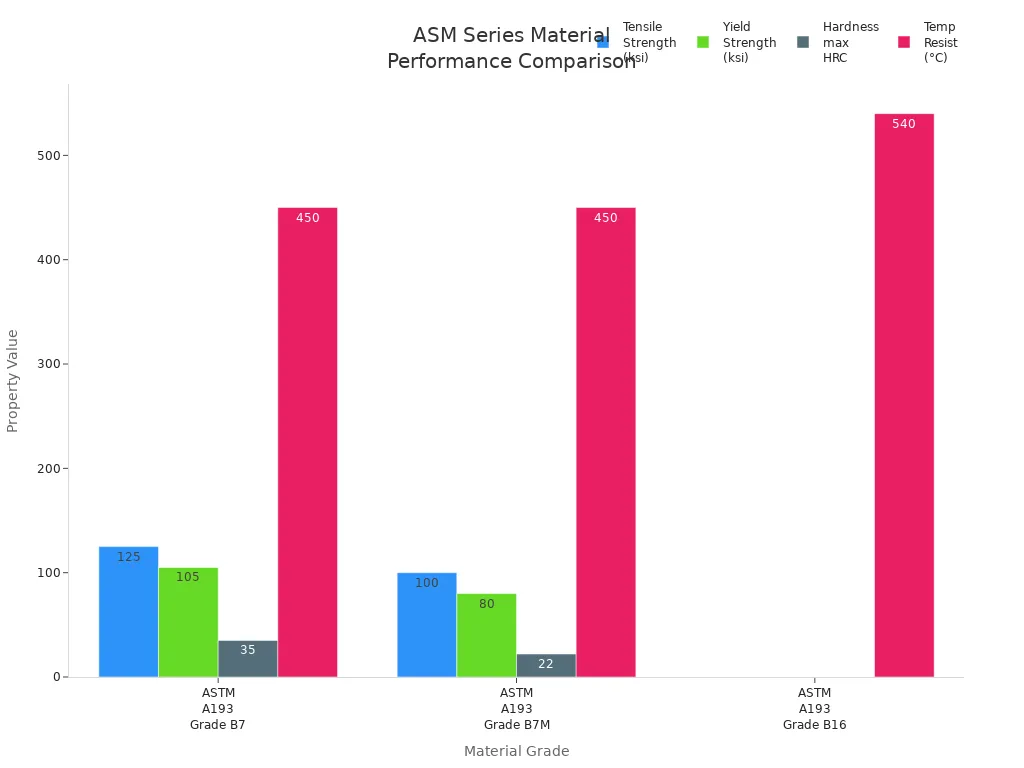

Material selection affects both performance and cost. The table below compares common material grades used in ASM Series components:

Material Grade | Composition & Key Features | Mechanical Properties | Temperature Resistance | Cost & Application Impact |

ASTM A193 Grade B7 | Chromium-molybdenum steel; balanced strength | Tensile ~125 ksi; Yield ~105 ksi; Hardness max 35 HRC | Up to ~450°C (840°F) | Cost-effective for high-pressure, high-temp use |

ASTM A193 Grade B7M | Modified for sour service; NACE MR0175 compliant | Tensile ~100 ksi; Yield ~80 ksi; Hardness max 22 HRC | Similar temp range; optimized for sour environments | Higher compliance costs; prevents sulfide stress cracking |

ASTM A193 Grade B16 | Chromium-molybdenum-vanadium steel; enhanced creep resistance | Higher strength and creep resistance | Up to ~540°C (1000°F) | Higher material costs; chosen for elevated temp applications |

You can see how material choice influences mechanical properties and cost. This helps you select the best option for your industry, especially if you need high structural integrity and durability.

ASM Series Customized Processing in China

When you choose ASM series customized processing in China, you follow a clear and structured process. Each step ensures that your requirements are met with precision and efficiency. Jiangxi Hongdu Precision Machinery Co., Ltd. guides you through every stage, using advanced equipment and strict quality control.

Consultation & Requirements

You start by sharing your project needs with the manufacturer. During this consultation, you describe your application, load requirements, and any special features you want. The team at Jiangxi Hongdu Precision Machinery Co., Ltd. listens carefully and asks questions to clarify your expectations. You define technical parameters, such as dimensions, material grades, and performance standards. This step sets the foundation for a successful project.

Tip: Clear communication at this stage helps prevent misunderstandings later. Prepare detailed drawings or specifications if possible.

Design & Prototyping

After you outline your requirements, the design team creates detailed drawings and 3D models. You review these designs and suggest changes if needed. Once you approve the design, the manufacturer produces a prototype. This prototype lets you check the fit, function, and quality before full production begins. Jiangxi Hongdu Precision Machinery Co., Ltd. uses advanced CAD software and precision machining tools to ensure accuracy.

Quotation & Order

With the design finalized, you receive a detailed quotation. This document lists material costs, processing fees, and estimated delivery times. You can compare options and make informed decisions. Once you confirm the order, the manufacturer schedules your project for production. Typically, you receive a quotation within 3 to 5 days after submitting your requirements.

Production & Quality

Production begins after you approve the order. Skilled technicians use advanced welding and assembly equipment to create your ASM Series components. Jiangxi Hongdu Precision Machinery Co., Ltd. follows strict quality control procedures at every stage. They test each part for strength, durability, and dimensional accuracy. You can request regular progress updates and even visit the facility if you want to see the process firsthand.

Note: Defining quality standards with your manufacturer ensures that the final product meets your expectations.

Delivery & Support

Once production finishes, the manufacturer prepares your order for shipment. The typical timeline for ASM series customized processing in China looks like this:

1. Receiving your request: 1 to 3 days

2. Product design and quotation: 3 to 5 days

3. Production: 14 to 30 days

You receive tracking information and estimated delivery dates. After delivery, Jiangxi Hongdu Precision Machinery Co., Ltd. offers responsive after-sales support. You can contact their team for technical assistance or to resolve any issues quickly.

By following this step-by-step process, you ensure that your ASM Series components meet your exact needs. The combination of advanced technology, clear communication, and strong quality control makes ASM series customized processing in China a reliable choice for demanding industrial applications.

Key Considerations

Manufacturer Selection

You should always choose a manufacturer with proven experience in ASM series customized processing in China. Jiangxi Hongdu Precision Machinery Co., Ltd. stands out with over 20 years of dedicated manufacturing for overseas customers. Their expertise covers complex welding assembly and structural load-bearing parts. The company uses advanced processing and testing equipment and holds qualification certificates. You benefit from their global customer service and strong track record in delivering customized solutions.

Communication

Clear communication ensures your project runs smoothly. You need to provide detailed drawings, specifications, and expectations from the start. Regular updates help you track progress and address any issues early. Good documentation prevents misunderstandings and keeps everyone on the same page. You can use email, phone, or online meetings to stay connected with your manufacturer.

Tip: Always confirm important details in writing to avoid confusion later.

Lead Time & MOQ

Understanding lead times and minimum order quantities (MOQ) helps you plan your project better. Ask your manufacturer for a clear production timeline before you place an order. Lead times can vary based on design complexity and material availability. Check the MOQ to ensure it matches your needs. Planning ahead reduces delays and helps you meet your deadlines.

Quality Assurance

Quality assurance protects your investment. Look for manufacturers who follow strict quality control processes and hold relevant certifications. Jiangxi Hongdu Precision Machinery Co., Ltd. meets international standards and uses advanced testing equipment. You can request inspection reports and test results for your ASM Series components. Reliable quality assurance gives you confidence in the final product.

Quality & Efficiency Tips

Sample Approval

You should always start with sample approval before moving to full production. Request a prototype or sample of your ASM Series component. This step lets you check the fit, finish, and function in real-world conditions. If you spot any issues, you can ask for adjustments early. Sample approval helps you avoid costly mistakes and ensures the final product matches your requirements.

Tip: Use the sample to test compatibility with your existing systems or machinery.

Progress Updates

Stay informed throughout the manufacturing process by requesting regular progress updates. Ask your manufacturer for photos, videos, or written reports at key stages. These updates help you track the timeline and catch any potential delays. Open communication also builds trust and keeps your project on schedule.

· Request updates after each major milestone, such as material procurement, assembly, and quality checks.

· Use these updates to clarify any questions or concerns right away.

Final Inspection

Before accepting delivery, conduct a final inspection of your ASM Series components. Review the quality reports and test results provided by the manufacturer. If possible, visit the facility or use video calls to inspect the products yourself. Final inspection ensures that every part meets your technical standards and performance needs.

Leveraging technical support and after-sales service can further improve long-term quality. Advanced support teams use real-time monitoring and AI-driven systems to detect defects, analyze root causes, and make precise corrections. This approach keeps your equipment running smoothly and adapts to changes in your production environment. Strong after-sales service also streamlines warranty claims and provides ongoing training, helping you maintain high standards over time.

You can achieve reliable results by following each step, from consultation to final inspection. Jiangxi Hongdu Precision Machinery Co., Ltd. delivers precision, quality, and responsive service. Reach out for a consultation to discuss your project needs. Take the next step to ensure your components meet your exact requirements.

FAQ

What industries use ASM Series customized components?

You find ASM Series components in construction, heavy machinery, energy, and manufacturing. These industries need strong, reliable load-bearing assemblies for safe operation.

Tip: Always check your industry’s standards before ordering ASM Series components.

How do you start a customization order with Jiangxi Hongdu Precision Machinery?

You send your requirements and drawings to the company. Their team reviews your needs and guides you through design, quotation, and production steps.

Can you request specific material grades for ASM Series components?

Yes, you choose from several material grades. The manufacturer helps you select the best option for your application and budget.

Material Grade | Common Use |

B7 | General load-bearing |

B7M | Sour environments |

B16 | High temperature |