Home / Resources / Blogs / Industry News / Generator Rotor Series in 2025: What’s New and How It Works

Generator Rotor Series in 2025: What’s New and How It Works

Image Source: pexels

A generator rotor series refers to a set of precision-engineered components that drive energy conversion in electrical machines. Precision and innovation shape modern rotors, ensuring reliable performance. Jiangxi Hongdu Preciosion Machinery leads the field with advanced solutions and expert craftsmanship.

Key Takeaways

· Generator rotor series convert mechanical energy into electrical energy with high precision, ensuring reliable performance in electric machines.

· Recent innovations in rotor design have improved energy efficiency by over 20%, making them more effective for high-temperature applications.

· Industries like automotive, mining, and energy benefit from advanced generator rotor technologies, leading to reduced downtime and enhanced reliability.

Generator Rotor Series Basics

Key Components

A generator rotor series consists of several critical elements that work together to convert mechanical energy into electrical energy. The arrangement of these components directly affects the performance and reliability of electric machines.

· The staggered dual-rotor configuration increases torque output and reduces torque ripple, which is essential for stable operation.

· Rotors positioned at a 90-degree electrical offset allow the salient poles to interleave, suppressing torque ripple through peak shaving and valley filling.

· The peak-to-peak no-load torque drops by 86.36% compared to conventional dual-rotor assemblies, resulting in improved reliability.

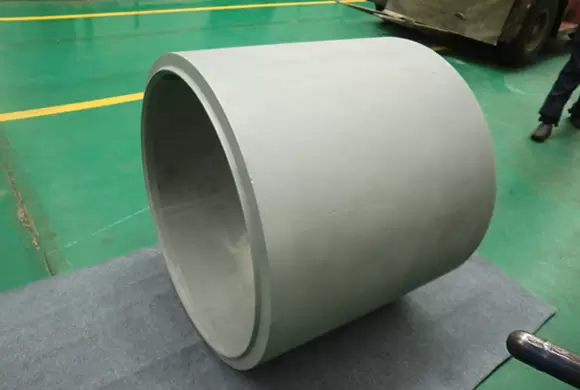

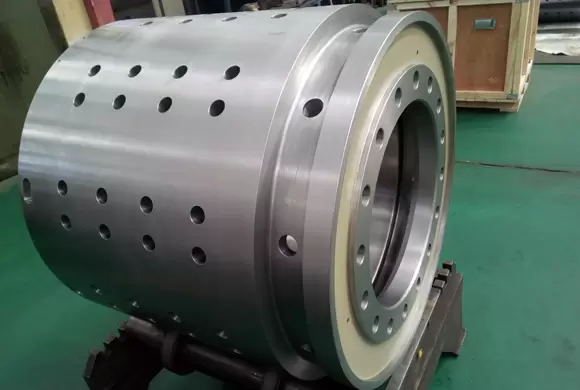

Jiangxi Hongdu Precision Machinery Co., Ltd. manufactures generator rotor series using an integral rotor design. The company uses high-quality carbon steel forging for each rotor, which ensures exceptional structural performance and durability.

Heat treatment plays a critical role in determining the mechanical properties, internal structure, and performance of forged components.

Each rotor meets strict precision requirements, with a minimum size tolerance of 0.025mm and a position tolerance of 0.03mm. The large size, often exceeding one ton, demonstrates the robust construction needed for heavy-duty machines.

How It Works

The generator rotor series operates as the heart of energy conversion in electric machines. The rotor synchronizes with the stator to produce electricity. The process follows the law of electromagnetic induction.

1. The handle of the generator is cranked, starting the conversion process.

2. A gear system transforms low-speed rotation into high-speed rotation, driving the rotor coil.

3. The rotor coil moves through the magnetic field created by the stator magnets, generating alternating current.

4. A diode array converts the alternating current into direct current.

5. A voltage regulator adjusts the current and voltage supply for electrical devices.

Approximately 60% of the mechanical energy becomes electrical energy, while the rest dissipates as heat. The output voltage depends on the strength of the magnetic field, the length of the wire, and the speed at which the coil cuts through the field. The rotor must synchronize with the stator to maintain consistent energy conversion and stable operation in machines.

2025 Innovations and Applications

New Technologies

Recent years have seen remarkable advancements in the design and manufacturing of generator rotor series. Engineers now focus on optimizing blade geometry, especially in regenerative flow turbines. This approach increases maximum power generation from 0.81 kW to 0.89 kW, a 9.42% improvement for high-temperature applications. Energy efficiency rises from 12.16% to 14.67%, marking a 20.64% gain. Exergy efficiency also improves, moving from 6.80% to 7.99%, a 17.45% increase. These gains result from precise engineering and advanced materials.

Jiangxi Hongdu Precision Machinery Co., Ltd. leads the industry by implementing integral rotor designs with high-quality carbon steel forging. Their manufacturing process achieves tight tolerances, which ensures consistent performance in demanding environments. The company’s expertise in producing large, robust rotors supports the needs of modern electric machines, including dc motors and series-wound motors.

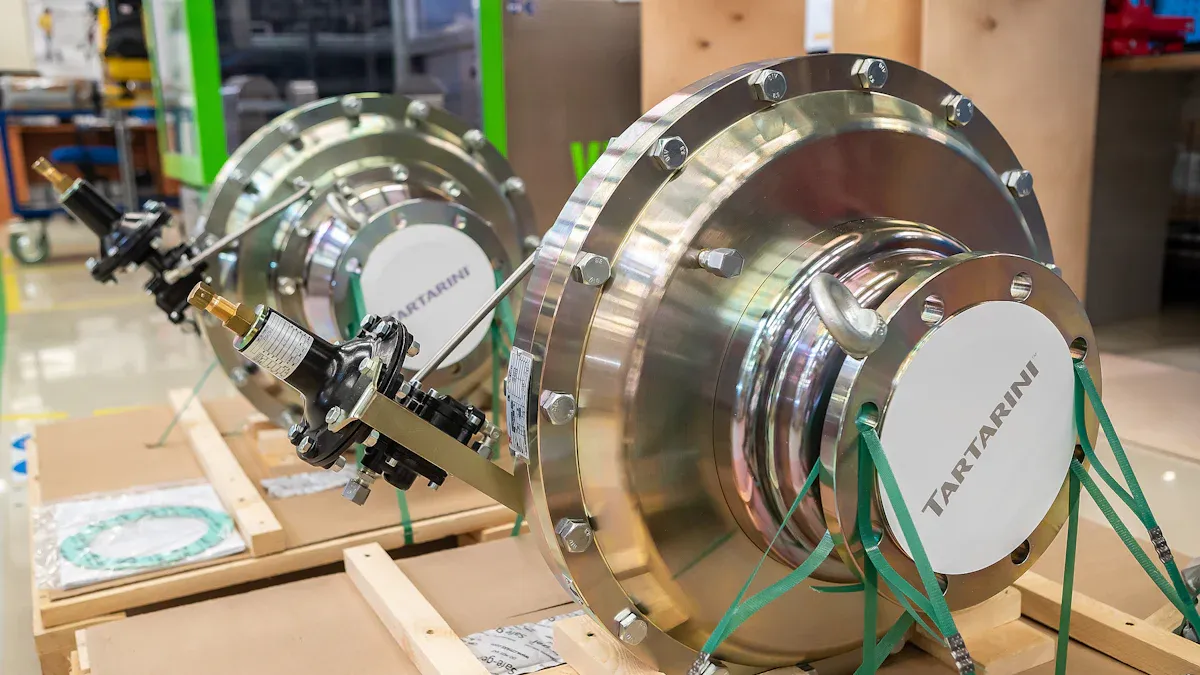

Innovations extend to hybrid generator designs. Triboelectric-electromagnetic hybrid generators now use vibration grading systems to collect energy from a wide range of frequencies and amplitudes. Bevel gear transmission systems with needle roller bearings convert mechanical vibration into rotational kinetic energy. This technology enables relative rotation between the magnet and the coil, doubling the efficiency compared to traditional single rotor structures. These systems also allow for the simultaneous collection of ocean wave and wind energy, expanding the possibilities for renewable power generation.

Performance and Efficiency

The latest generator rotor series deliver significant improvements in performance and reliability. Engineers use advanced monitoring techniques to ensure long-term stability. The following table summarizes key monitoring methods and their importance:

Monitoring Technique | Importance |

Temperature Monitoring | Indicates lubrication issues, misalignment, or wear through heat generation. |

Vibration Analysis | Detects mechanical problems like imbalance or bearing defects through frequency components. |

Electrical Parameter Monitoring | Identifies rotor issues and power quality problems through current and voltage analysis. |

Oil Analysis | Assesses lubricant condition and wear particles affecting equipment reliability. |

Process Parameter Monitoring | Provides context for operational efficiency and distinguishes between equipment and process issues. |

These monitoring strategies help maintain optimal operation in dc motors and generator rotor series. The integration of dynamic pitch control algorithms in aerodynamic modeling maximizes energy capture and ensures safety in changing wind conditions. Drivetrain mechanics simulate gearbox efficiency and rotational dynamics, reducing mechanical losses during speed conversion from turbine shafts to generator inputs. Electrical conversion focuses on permanent magnet synchronous generators (PMSG) and power electronics, simulating electromagnetic interactions, voltage regulation, and frequency control for grid compatibility. Grid connection modeling evaluates system interactions with the electrical network, including load balancing and power flow analysis to maintain grid stability.

Jiangxi Hongdu Precision Machinery Co., Ltd. sets industry standards by delivering generator rotor series with exceptional precision. Their products support high-performance dc motors and series-wound motors, which require reliable and efficient operation. The company’s commitment to quality ensures that each rotor meets strict size and position tolerances, contributing to the overall efficiency of electric machines.

Generator Rotor Series in Industry

Industries such as automotive, mining, and energy benefit from the latest generator rotor series. The robust construction and large size of these rotors make them suitable for heavy-duty applications. In the automotive sector, dc motors and series-wound motors rely on precise rotor engineering for consistent performance. Mining operations use generator rotor series to power large machinery, where reliability and efficiency are critical. The energy sector integrates these rotors into renewable systems, supporting wind and ocean energy projects.

Aspect of Integration | Description |

Aerodynamic Modeling | Incorporates dynamic pitch control algorithms to maximize energy capture and ensure safety across varying wind conditions. |

Drivetrain Mechanics | Simulates gearbox efficiency, rotational dynamics, and mechanical losses during speed conversion from turbine shafts to generator inputs. |

Electrical Conversion | Focuses on PMSG and power electronics, simulating electromagnetic interactions, voltage regulation, and frequency control necessary for grid compatibility. |

Grid Connection Modeling | Evaluates system interactions with the electrical network, including load balancing and power flow analysis to maintain grid stability. |

Industrial users recognize the value of adopting new generator rotor technologies. While initial costs and installation expenses can be significant, the long-term benefits include improved efficiency, reduced downtime, and enhanced reliability. Jiangxi Hongdu Precision Machinery Co., Ltd. continues to support these industries by providing advanced solutions tailored to their specific needs.

Note: The adoption of advanced generator rotor series supports the transition to more sustainable and efficient energy systems. Precision engineering remains essential for the future of dc motors and series-wound motors in all major industries.

Generator rotor series play a vital role in electric machines by converting energy with high precision. Recent innovations in 2025 boost both performance and reliability.

Jiangxi Hongdu Precision Machinery Co., Ltd. offers advanced solutions. Precision engineering remains essential for future progress in electric machine technology.

FAQ

What makes the Generator Rotor Series from Jiangxi Hongdu Precision Machinery Co., Ltd. unique?

The series uses integral rotors forged from carbon steel. Precision tolerances reach 0.025mm. Large units weigh over one ton, supporting heavy-duty industrial applications.

Which industries benefit most from advanced generator rotor series?

· Automotive

· Mining

· Energy

These sectors require reliable, efficient rotors for consistent machine performance and long-term durability.

How does precision engineering improve generator rotor performance?

Benefit | Description |

Efficiency | Precision reduces energy loss. |

Reliability | Tight tolerances prevent failures. |

Longevity | Robust design extends service life. |