Home / Resources / Blogs / Industry News / Advanced Aluminum Casting Process for High-Quality Metal Components

Advanced Aluminum Casting Process for High-Quality Metal Components

In today’s modern manufacturing industry, aluminum has become one of the most widely used metals due to its lightweight properties, excellent strength-to-weight ratio, corrosion resistance, and recyclability. From automotive and aerospace to construction and consumer electronics, aluminum plays a crucial role in creating durable yet lightweight components.

At the heart of this transformation lies the aluminum casting process, a sophisticated manufacturing technique that enables the production of high-precision and high-quality metal components. With continuous advancements in technology, the casting process has evolved to deliver better accuracy, surface finish, and performance efficiency.

What Is the Aluminum Casting Process?

The aluminum casting process is a method of shaping molten aluminum into desired forms by pouring it into a mold. Once the aluminum cools and solidifies, the mold is removed, resulting in a strong, lightweight component ready for further finishing or assembly.

This process is preferred across industries because it allows manufacturers to create complex geometries, thin walls, and intricate details that are otherwise difficult to achieve with traditional machining.

Types of Aluminum Casting Processes

There are several methods of aluminum casting, each with specific advantages depending on the application:

1. Die Casting

Involves injecting molten aluminum into steel molds under high pressure.

Produces highly accurate parts with smooth surfaces.

Ideal for mass production of automotive, electronic, and industrial components.

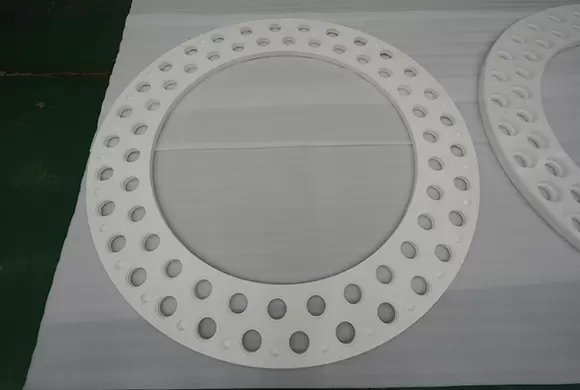

2. Sand Casting

Uses sand molds that can be easily formed and reshaped.

Offers flexibility in producing large and complex components.

Commonly used in aerospace, marine, and heavy machinery applications.

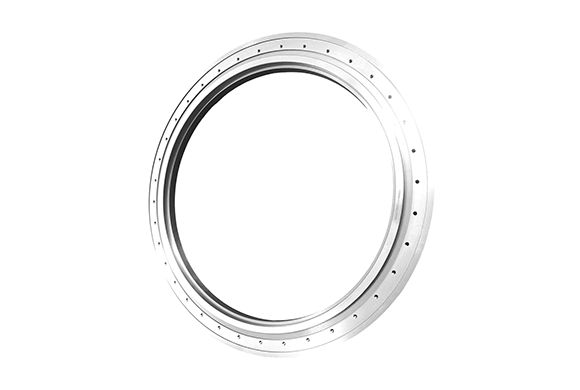

3. Gravity Casting

Molten aluminum is poured into a mold without applying external pressure.

Provides strong and durable components with excellent dimensional accuracy.

Suitable for medium production runs.

4. Investment Casting

Also known as precision casting, it involves creating a wax model coated with ceramic material to form a mold.

Produces components with extremely fine details and tight tolerances.

Used in aerospace, defense, and medical industries.

Advantages of the Advanced Aluminum Casting Process

The evolution of advanced aluminum casting techniques brings significant benefits to modern manufacturing:

High Dimensional Accuracy – Advanced molds and automated casting systems ensure consistent precision.

Lightweight Strength – Aluminum components maintain structural integrity while reducing overall weight.

Cost Efficiency – High-volume production and recyclability of aluminum lower long-term manufacturing costs.

Corrosion Resistance – Cast aluminum resists oxidation and harsh environmental conditions.

Versatility – The process supports a wide range of component sizes, from small parts to large industrial structures.

Eco-Friendly – Aluminum is 100% recyclable, making it an environmentally sustainable choice.

Applications of Aluminum Casting in Industries

Because of its performance and flexibility, the aluminum casting process is used across diverse sectors:

Automotive Industry – Engine blocks, transmission housings, and structural components.

Aerospace Sector – Lightweight yet strong turbine blades, brackets, and airframe parts.

Construction – Window frames, panels, and support structures requiring durability.

Consumer Electronics – Heat sinks, casings, and precision housings for electronic devices.

Marine Industry – Corrosion-resistant propellers and ship components.

Industrial Machinery – Heavy-duty parts with high wear resistance.

Technological Innovations in Aluminum Casting

Modern manufacturing has introduced several innovations to enhance the casting process:

Computer-Aided Design (CAD) and Simulation – Helps in designing molds and predicting casting performance before production.

Automated Casting Systems – Ensure precision, repeatability, and reduced human error.

Vacuum Die Casting – Minimizes porosity in cast parts, leading to superior mechanical properties.

3D Printing of Molds – Accelerates prototyping and reduces lead times in mold production.

Heat Treatment Enhancements – Improve strength, hardness, and wear resistance of aluminum castings.

Why Choose Advanced Aluminum Casting for High-Quality Metal Components?

Businesses across the globe prefer advanced aluminum casting because it combines design flexibility, mechanical performance, and cost-effectiveness. Whether for large-scale industrial production or small specialized components, the process ensures high quality, consistency, and adaptability.

Manufacturers seeking to remain competitive in today’s demanding markets must rely on efficient and reliable casting technologies that deliver superior results while minimizing material waste and energy consumption. Advanced aluminum casting meets these requirements, making it the preferred choice for industries focused on innovation and sustainability.

Conclusion

The advanced aluminum casting process is reshaping the way industries design and manufacture high-quality components. With its ability to produce precise, durable, lightweight, and corrosion-resistant parts, aluminum casting has become indispensable in sectors such as automotive, aerospace, construction, and electronics.

As technology continues to evolve, the integration of automation, digital design, and sustainable practices will further enhance the efficiency, consistency, and environmental benefits of the aluminum casting process.

For businesses aiming to improve performance and reduce costs while supporting eco-friendly manufacturing, investing in advanced aluminum casting solutions is a forward-looking choice.