Home / Resources / Blogs / Industry News / Precision Engine Flywheel Machined Components for Reliable Power Transmission

Precision Engine Flywheel Machined Components for Reliable Power Transmission

Engine performance, efficiency, and reliability depend heavily on the quality of the components used in power transmission systems. Among these, Jiangxi Hongdu Preciosion Machinery's engine flywheel machined components play a critical role in ensuring smooth torque delivery, reducing vibration, and maintaining engine balance. Designed for precision and durability, these machined parts are essential for modern automotive, industrial, and heavy-duty engine applications.

What Are Engine Flywheel Machined Components?

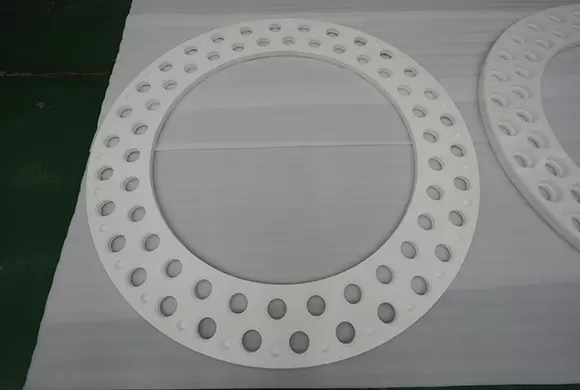

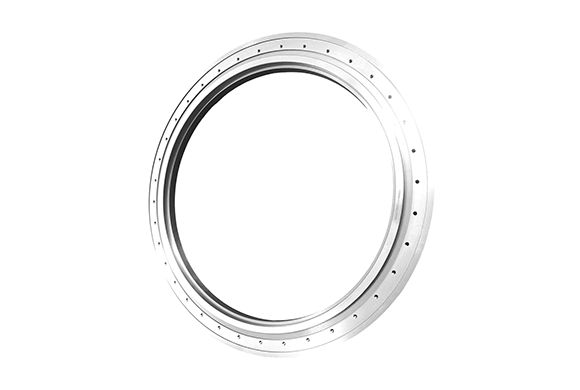

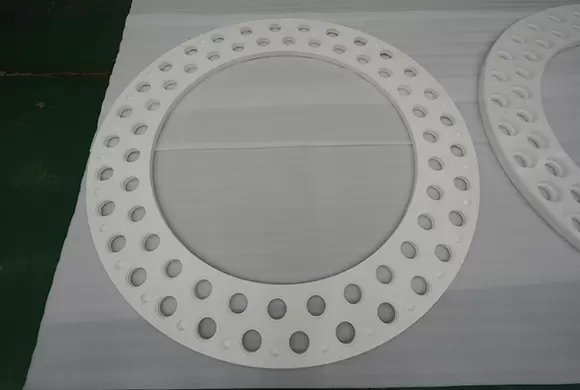

Flywheels are rotating mechanical devices that store and release rotational energy to maintain consistent engine operation. Machined flywheel components are produced using high-precision CNC machining processes, ensuring tight tolerances, balanced mass distribution, and superior surface finishes. These components typically include the flywheel itself, hub assemblies, mounting rings, and associated machined interfaces that connect the flywheel to the crankshaft and clutch system.

Key Advantages of Precision Machined Flywheel Components

1. High Accuracy and Tight Tolerances

Precision machining guarantees that every flywheel component meets exact design specifications. This reduces mechanical stress on the engine, minimizes wear, and ensures smooth engagement with other drivetrain components.

2. Enhanced Engine Balance

Properly machined flywheels reduce vibration and harmonic imbalance. This not only improves engine efficiency but also prolongs the life of bearings, gears, and other critical components.

3. Superior Material Performance

High-quality materials, including forged steel, alloy steel, and aluminum alloys, are commonly used in machined flywheel production. These materials provide high strength-to-weight ratios, excellent fatigue resistance, and reliable heat dissipation.

4. Improved Torque Transmission

The precise surface finish and dimensional accuracy of machined flywheels allow for efficient torque transfer from the engine to the drivetrain. This is particularly important in high-performance engines where power delivery must be consistent and responsive.

5. Longevity and Durability

Precision machined components experience less stress concentration and wear over time. This leads to longer service life and reduced maintenance costs, making them ideal for industrial engines, commercial vehicles, and high-demand automotive applications.

Applications of Engine Flywheel Machined Components

Machined flywheel components are versatile and widely used across different sectors:

Automotive Industry: Passenger cars, sports cars, and high-performance vehicles rely on precisely machined flywheels for smooth operation and reliable power transmission.

Commercial Vehicles: Trucks, buses, and construction machinery benefit from durable flywheel assemblies that withstand heavy loads and frequent start-stop cycles.

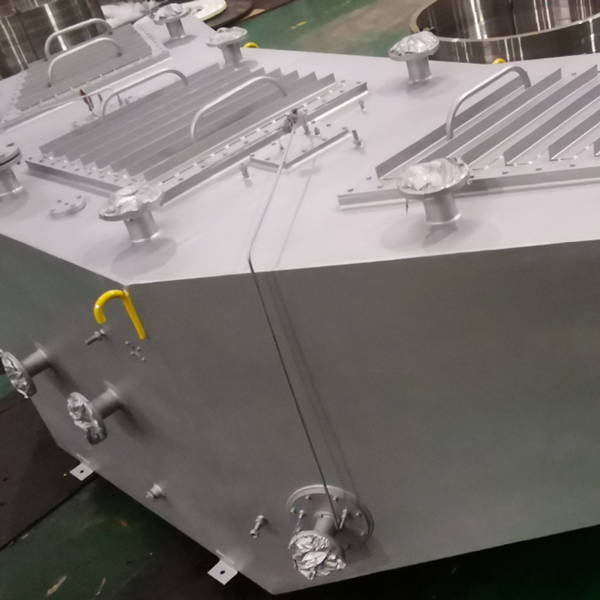

Industrial Engines: Diesel engines, generators, and marine engines require machined flywheels for stable torque output and minimized vibrations.

Aftermarket and OEM Solutions: Machined flywheel components are supplied to engine manufacturers as well as replacement part markets to ensure consistent performance standards.

Why Choose CNC Machined Flywheel Components?

CNC machining offers several advantages over traditional manufacturing methods:

Consistent Precision: Computer-controlled machining maintains uniform tolerances across multiple production runs.

Customizable Designs: Machined components can be tailored to meet specific engine configurations and performance requirements.

Reduced Lead Time: Automated processes increase production efficiency without compromising quality.

Quality Assurance: Each component can undergo rigorous inspection and testing to ensure it meets industry standards.

Conclusion

Precision engine flywheel machined components are indispensable for reliable power transmission in modern engines. From enhancing torque efficiency and engine balance to ensuring long-term durability, these components provide significant performance and maintenance advantages. Whether for automotive, industrial, or heavy-duty applications, investing in high-quality machined flywheel assemblies ensures your engines operate at peak efficiency with minimal vibration and wear.