Home / Resources / Blogs / Industry News / Industrial Machine Parts: Ensuring Efficiency and Durability in Modern Manufacturing

Industrial Machine Parts: Ensuring Efficiency and Durability in Modern Manufacturing

In the fast-paced world of modern manufacturing, efficiency, reliability, and precision are paramount. Every component of a production line plays a critical role in achieving these goals, and industrial machine parts form the backbone of operational performance. From heavy machinery to precision tools, high-quality machine parts ensure smooth operations, minimize downtime, and maintain product quality.

Understanding the importance of these components is essential for manufacturers aiming to enhance productivity, reduce maintenance costs, and extend the lifespan of their equipment.

What Are Industrial Machine Parts

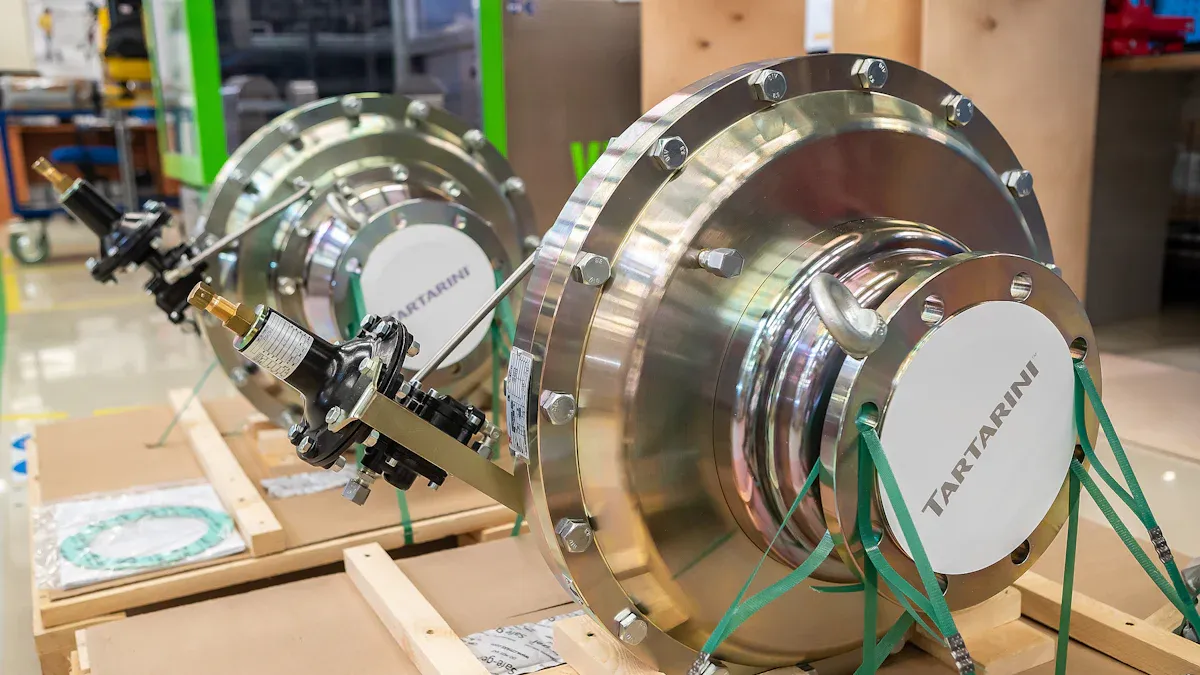

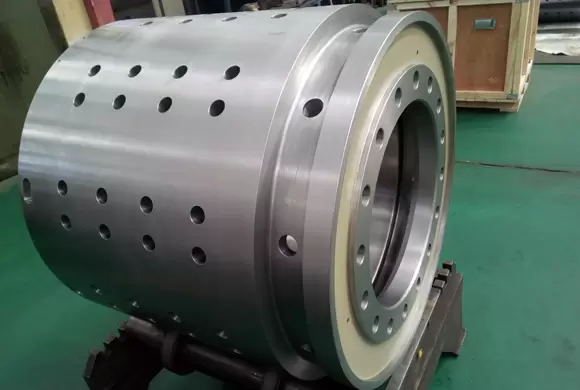

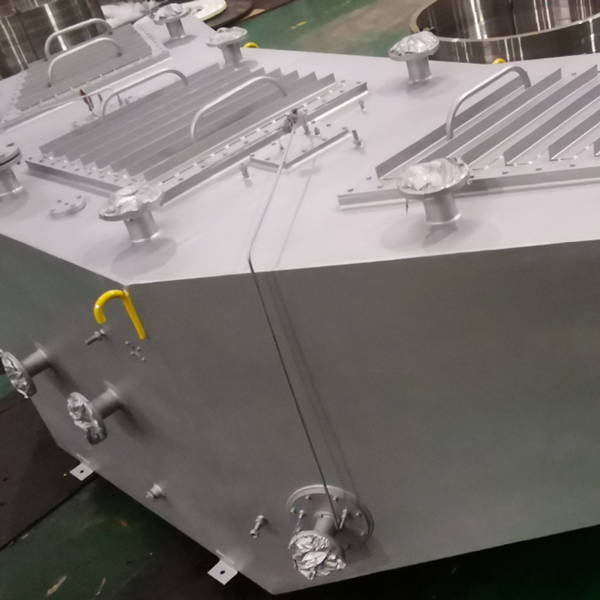

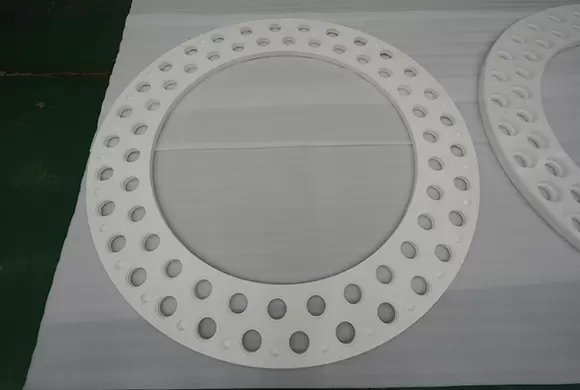

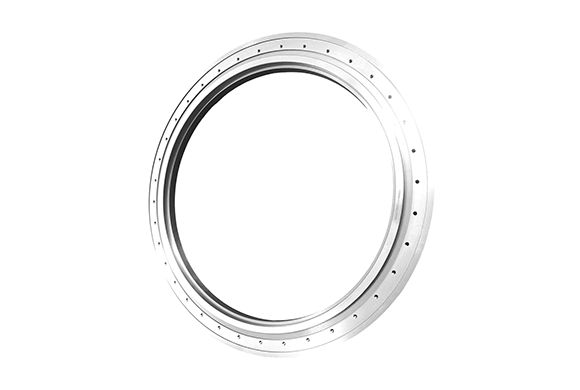

Industrial machine parts encompass a wide range of components used in manufacturing equipment, including gears, bearings, shafts, couplings, pulleys, and more. These parts can be made from various materials such as steel, aluminum, or composite alloys, depending on their function and required durability.

Machine parts are designed to withstand high stress, friction, and repetitive motion while maintaining precision. Proper selection, installation, and maintenance of these components are crucial for ensuring machinery operates at peak efficiency.

Key Features of High-Quality Industrial Machine Parts

Durability – Industrial machine parts are engineered to handle rigorous operating conditions and heavy loads without premature wear.

Precision Engineering – Accurate manufacturing tolerances ensure components fit perfectly, reducing vibration, noise, and energy loss.

Material Strength – Using robust materials like high-grade steel or reinforced alloys increases resistance to corrosion, fatigue, and impact.

Versatility – Components are designed to fit a variety of machines, allowing manufacturers to standardize parts across multiple production lines.

Ease of Maintenance – Modular designs and high-quality finishes make inspection, replacement, and maintenance straightforward, minimizing downtime.

Applications Across Industries

Industrial machine parts are essential across multiple sectors, including:

Automotive Manufacturing: Ensures engines, transmissions, and assembly lines operate efficiently and reliably.

Food and Beverage Processing: Maintains hygiene and precision in machinery used for mixing, packaging, and processing.

Textile and Apparel Production: Supports high-speed machinery, including looms, cutters, and printers.

Mining and Construction: Heavy-duty parts withstand extreme stress in earthmoving equipment, crushers, and conveyors.

Electronics and Precision Manufacturing: Critical components guarantee accuracy in assembly lines and testing equipment.

Benefits of Using High-Quality Industrial Machine Parts

Enhanced Efficiency – Smooth operation reduces energy consumption and increases output, ensuring production deadlines are met.

Reduced Downtime – Durable, reliable parts lower the risk of unexpected breakdowns, saving time and costs.

Improved Safety – Well-engineered components reduce mechanical failures that could lead to workplace accidents.

Extended Machinery Lifespan – Quality parts reduce wear and tear on entire machines, prolonging operational life.

Cost Savings – Investing in premium components decreases maintenance expenses and replacement frequency.

Choosing the Right Industrial Machine Parts

Selecting the right parts requires consideration of several factors:

Compatibility – Parts must match machine specifications for size, torque, and load capacity.

Material Properties – Consider corrosion resistance, heat tolerance, and fatigue strength based on application.

Supplier Reliability – Partnering with trusted manufacturers ensures consistent quality and availability.

Maintenance Requirements – Opt for parts that are easy to inspect and replace to minimize production downtime.

Conclusion

Industrial machine parts are the foundation of modern manufacturing efficiency and durability. Investing in high-quality components ensures smooth operations, reduces maintenance costs, and extends the life of machinery. From automotive assembly lines to heavy-duty mining equipment, reliable machine parts enable manufacturers to meet production targets safely and cost-effectively.

By prioritizing precision-engineered, durable, and compatible components, businesses can achieve higher productivity, lower operational risks, and maintain competitive advantages in today’s industrial landscape.

For more product details, please see: Industrial Machine Parts – Jiangxi Hongdu Preciosion Machinery