Home / Resources / Blogs / Industry News / Application and Advantages of Customized Machining of Mechanical Equipment Parts

Application and Advantages of Customized Machining of Mechanical Equipment Parts

In today’s fast-paced industrial environment, precision, durability, and efficiency are the foundation of reliable machinery. Mechanical equipment across industries such as manufacturing, automotive, energy, construction, and aerospace depends heavily on well-crafted components to function optimally. Customized machining of mechanical equipment parts has become an indispensable solution, enabling businesses to achieve superior performance, tailored designs, and long-term cost savings.

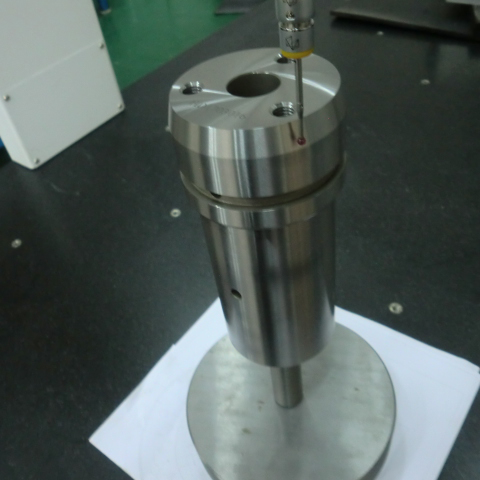

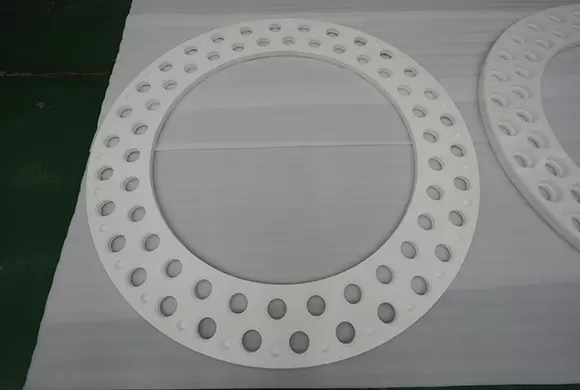

Unlike standard, mass-produced parts, customized machining focuses on producing components that match exact specifications, tolerances, and application requirements. Through advanced CNC machining, milling, turning, and surface finishing technologies, manufacturers are able to deliver parts that meet stringent industry standards while addressing unique customer needs.

What Is Customized Machining of Mechanical Equipment Parts

Customized machining refers to the process of manufacturing equipment parts according to specific customer requirements rather than generic mass production. Using modern CNC (Computer Numerical Control) machines, raw materials such as steel, aluminum, titanium, brass, and high-performance alloys are precisely shaped into components with tight tolerances and complex geometries.

Key capabilities of customized machining include:

High-precision dimensional control for complex parts.

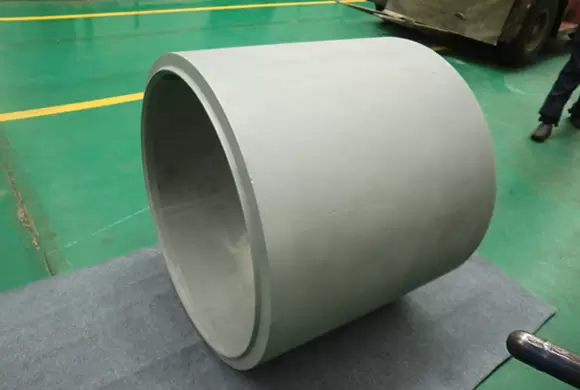

Flexibility in material selection based on strength, corrosion resistance, or weight requirements.

Integration of advanced processes like drilling, milling, grinding, and surface finishing.

Production scalability from prototypes to small or large batches.

This level of flexibility ensures that every component aligns perfectly with the mechanical system in which it will be used.

Applications of Customized Machining in Mechanical Equipment

Customized machining plays a critical role across numerous industries that demand accuracy and performance. Common applications include:

Manufacturing Industry

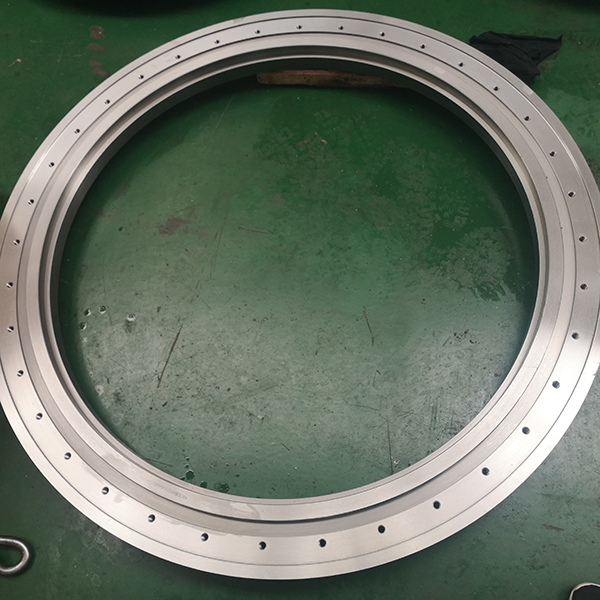

Precision-machined gears, bearings, and housings for production machinery ensure seamless operation and reduced downtime.

Automotive and Transportation

Engine components, transmission parts, and structural elements are custom-machined to enhance vehicle performance, efficiency, and safety.

Aerospace and Defense

High-strength, lightweight, and precision-machined parts are essential for aircraft engines, landing gear, and navigation systems.

Energy Sector

Turbine blades, pumps, and valve components require customized machining to handle extreme pressures, temperatures, and environmental conditions.

Construction and Heavy Equipment

Excavators, loaders, and cranes rely on robust custom-machined joints, brackets, and shafts to handle heavy-duty workloads.

Medical Equipment

Customized machining ensures precision in surgical instruments, implants, and diagnostic devices, where accuracy is critical.

From prototypes to fully integrated industrial systems, customized machining enhances both reliability and functionality.

Advantages of Customized Machining of Mechanical Equipment Parts

1. Precision and Accuracy

Customized machining guarantees tight tolerances and exact dimensions. This ensures compatibility with existing systems and smooth operation even in complex assemblies.

2. Enhanced Equipment Performance

Well-machined components improve overall equipment efficiency, reduce wear and tear, and minimize the risk of mechanical failures.

3. Flexibility in Design

Unlike standard parts, custom machining enables unique geometries, complex shapes, and tailored surface finishes to meet specific project requirements.

4. Material Optimization

Different industries require specific material properties, such as corrosion resistance in marine applications or high strength in aerospace. Customized machining offers the flexibility to select the best material for each component.

5. Cost-Effectiveness in the Long Run

Although custom machining may require higher upfront investment compared to standard parts, the long-term savings from reduced maintenance, improved efficiency, and extended equipment lifespan outweigh the costs.

6. Rapid Prototyping and Innovation

Custom machining supports product development by allowing quick prototyping and testing, enabling faster innovation and adaptation to market demands.

The Role of Advanced CNC Machining in Custom Manufacturing

The success of customized machining is driven by advanced CNC technologies, which allow automation, repeatability, and precision. Modern CNC machines can operate continuously with minimal error, ensuring consistency even in large-scale production.

Benefits of CNC in custom machining include:

High repeatability – Every part is identical to the design specifications.

Shorter lead times – Faster turnaround compared to traditional manual machining.

Complex geometry capability – Ability to produce intricate parts that are impossible with conventional methods.

Reduced waste – Optimized programming minimizes material loss and improves cost-efficiency.

Conclusion

The application and advantages of customized machining of mechanical equipment parts highlight its critical role in modern industries. By enabling precise manufacturing, flexible design, and tailored solutions, custom machining not only improves equipment reliability but also contributes to cost savings and long-term efficiency.

From aerospace to automotive, energy to construction, customized machining ensures that businesses can achieve optimal performance with components designed specifically for their needs. As industries continue to evolve, the demand for customized machining solutions will only grow, making it an essential part of innovation and sustainable manufacturing.