Home / Resources / Blogs / Industry News / Precision Machined Shafts: Key Components for Improving Mechanical Performance

Precision Machined Shafts: Key Components for Improving Mechanical Performance

In modern machinery and industrial applications, precision, durability, and efficiency are critical to achieving long-term performance. Among the many components that contribute to mechanical systems, precision machined shafts stand out as essential parts that directly influence functionality and reliability. From automotive powertrains to aerospace systems, Jiangxi Hongdu precision shafts are designed to handle demanding loads, ensure smooth motion, and maintain stability under challenging operating conditions.

What Are Precision Machined Shafts

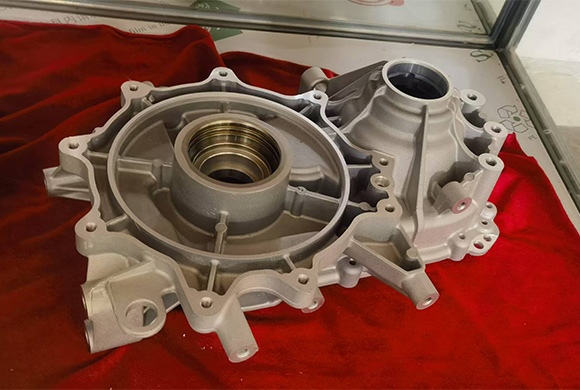

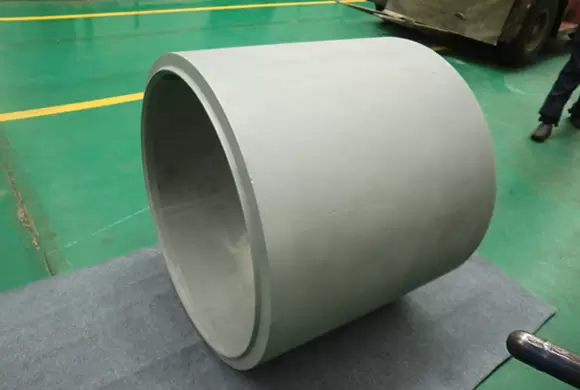

Precision machined shafts are high-quality cylindrical components manufactured through advanced machining processes such as CNC turning, grinding, and milling. These processes ensure tight dimensional tolerances, smooth finishes, and consistent geometry. Unlike standard shafts, precision shafts are specifically engineered to deliver superior alignment, rotational accuracy, and load-bearing capacity.

They are commonly produced from durable materials like stainless steel, carbon steel, alloy steel, and sometimes non-ferrous metals depending on the application requirements. Their ability to maintain accuracy and stability over extended use makes them indispensable in mechanical engineering.

Advantages of Precision Machined Shafts

1. Enhanced Dimensional Accuracy

One of the primary benefits of precision machined shafts is their ability to meet strict dimensional tolerances. This ensures consistent performance in assemblies where even the smallest deviation can affect functionality.

2. Superior Mechanical Strength

Made from high-quality metals and alloys, precision shafts offer exceptional tensile strength and resistance to wear. This durability allows them to withstand heavy loads, high rotational speeds, and challenging environmental conditions.

3. Improved Efficiency in Power Transmission

A precisely manufactured shaft ensures smooth rotation and alignment, reducing friction and minimizing energy loss. This results in higher efficiency and lower operating costs.

4. Extended Service Life

Precision machining reduces surface irregularities, which minimizes wear and tear. As a result, these shafts require less frequent replacement, lowering long-term maintenance costs.

5. Versatility in Applications

Precision machined shafts are highly customizable, with options for length, diameter, keyways, splines, threads, and surface treatments. This versatility makes them suitable for a wide range of industries.

Common Applications of Precision Machined Shafts

Automotive Industry – Used in engines, transmissions, and drive systems to ensure reliable power delivery.

Aerospace Engineering – Provide critical precision for aircraft systems where reliability and safety are paramount.

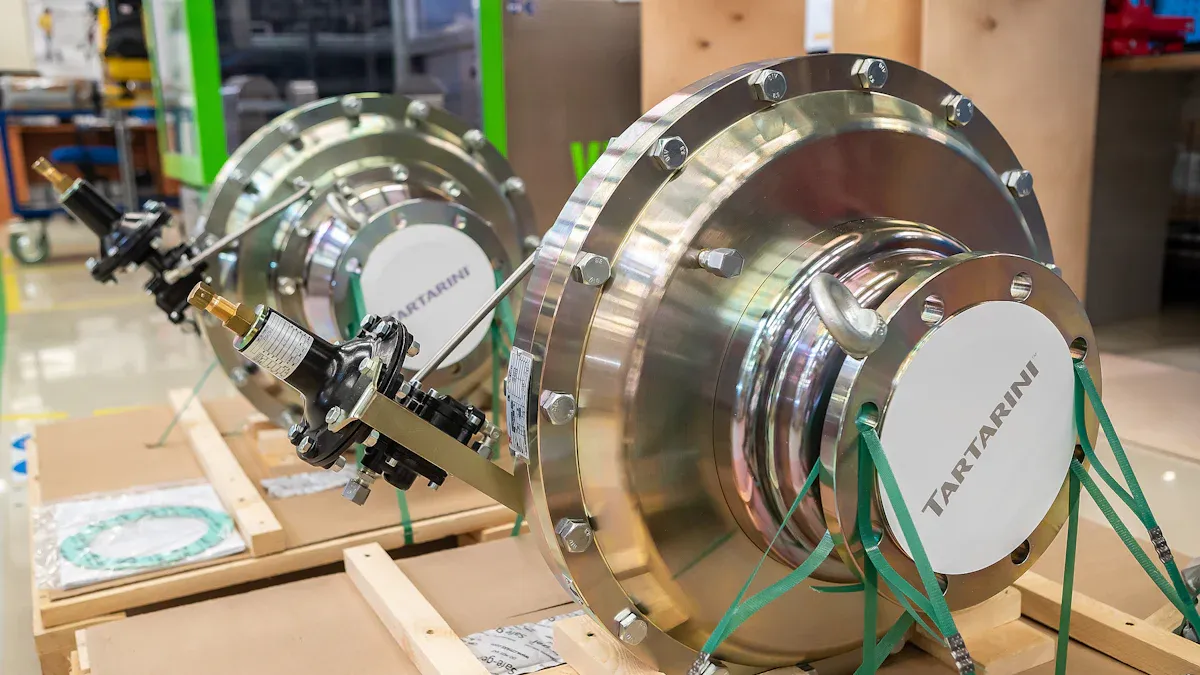

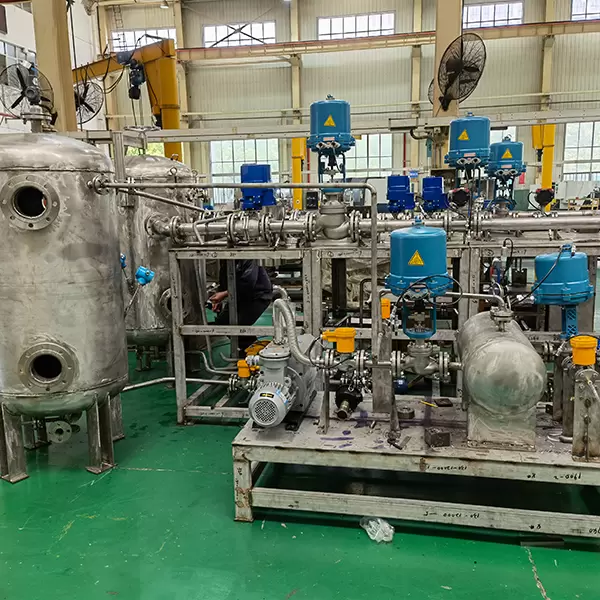

Industrial Machinery – Essential in pumps, compressors, conveyors, and heavy equipment requiring smooth motion.

Medical Equipment – Enable precision movement in devices such as imaging machines and robotic surgical tools.

Energy and Power Generation – Utilized in turbines, generators, and wind energy systems where stability is critical.

Factors to Consider When Selecting Precision Machined Shafts

Material Selection: Choose materials based on load requirements, operating environment, and corrosion resistance needs.

Dimensional Tolerances: Ensure the shaft meets the exact tolerances required for the application.

Surface Treatment: Options like heat treatment, plating, or coating can enhance wear resistance and extend service life.

Customization: Consider whether you need features such as splines, keyways, or threading.

Cost vs. Performance: Balance budget constraints with the required level of precision and durability.

Why Precision Machined Shafts Matter

In today’s competitive industrial landscape, small improvements in performance can lead to significant cost savings and efficiency gains. Precision machined shafts are not just components—they are performance enablers. By ensuring smooth operation, reliable load transfer, and longer service life, they contribute to the overall productivity and sustainability of mechanical systems.

Conclusion

Precision machined shafts play a vital role in enhancing the mechanical performance of modern equipment across diverse industries. With their superior strength, dimensional accuracy, and ability to improve efficiency, these shafts provide long-term value in demanding applications. Choosing the right material, tolerances, and machining process ensures optimal performance and reliability.

As industries continue to evolve toward higher efficiency and precision, the importance of precision machined shafts will only increase, making them a cornerstone of innovation in mechanical engineering.

For more product details, please see: Precision Machined Shafts – Jiangxi Hongdu Precision Machinery