Home / Resources / Blogs / Industry News / Material Selection and Performance Analysis of Casting Parts

Material Selection and Performance Analysis of Casting Parts

Casting is one of the most widely used manufacturing processes in the industrial world, playing a crucial role in automotive, aerospace, construction, energy, and machinery applications. The performance of casting parts is not determined only by design or production methods but also by the careful selection of materials. Each alloy or metal brings unique mechanical properties, durability, and resistance to specific working conditions. Understanding how to choose the right material and analyze its performance is essential for ensuring product reliability and longevity.

Importance of Material Selection in Casting

Material selection is the foundation of successful casting. A casting part must endure different stresses such as mechanical load, thermal expansion, corrosion, and wear depending on its application. The choice of material influences:

Strength and durability – The ability to withstand static or dynamic forces without deformation.

Heat resistance – Crucial for parts used in engines, turbines, and furnaces.

Corrosion resistance – Essential for marine, chemical, or outdoor environments.

Weight efficiency – Lighter materials may reduce energy consumption in transportation or machinery.

Cost-effectiveness – Selecting the right material ensures balance between performance and budget.

An improper choice can lead to premature failure, higher maintenance costs, and safety risks.

Common Materials Used in Casting Parts

1. Cast Iron

Cast iron is one of the oldest and most common casting materials. It offers:

Excellent wear resistance.

High compressive strength.

Good machinability.

Applications include engine blocks, pipes, pump housings, and construction equipment.

2. Carbon Steel

Carbon steel provides outstanding strength and toughness. Its characteristics are:

High mechanical performance.

Wide range of grades for different hardness levels.

Suitable for high-stress industrial parts.

It is often used in gears, shafts, and structural components.

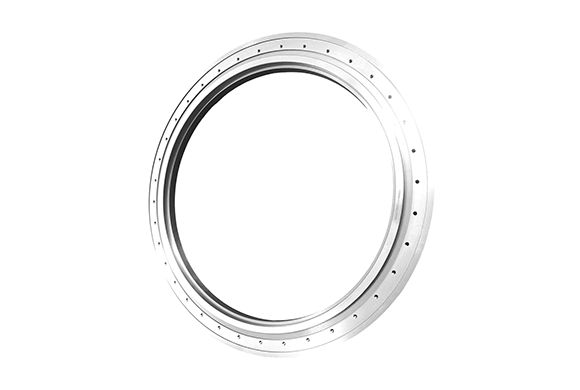

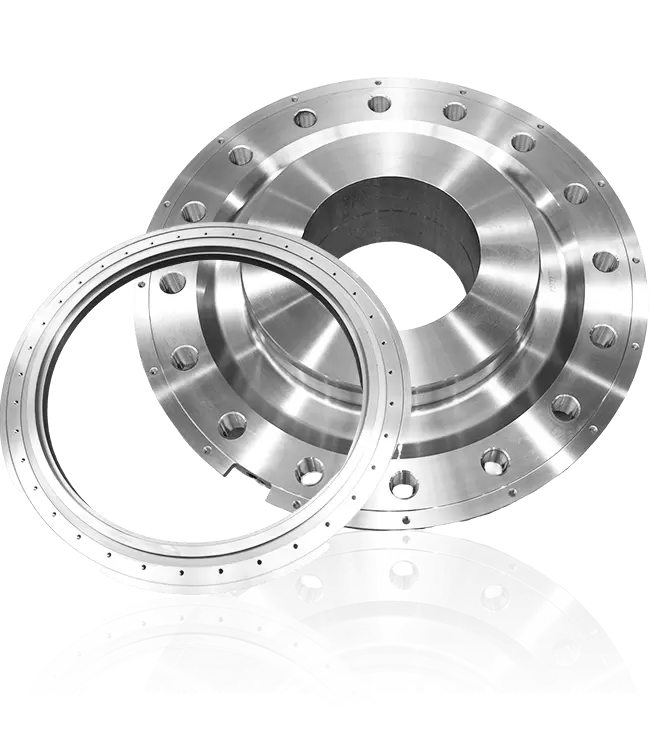

3. Stainless Steel

Stainless steel casting is valued for:

Superior corrosion resistance.

Excellent surface finish.

Good performance in extreme temperatures.

This makes it ideal for food processing equipment, medical devices, and marine components.

4. Aluminum Alloys

Aluminum is lightweight and versatile, offering:

Low density for weight-sensitive applications.

Good corrosion resistance.

Excellent thermal conductivity.

It is widely applied in automotive engine parts, aerospace structures, and consumer products.

5. Copper Alloys (Bronze & Brass)

Copper-based alloys are used for their:

High corrosion resistance in marine and chemical environments.

Good wear resistance.

Attractive appearance for architectural uses.

Common parts include valves, bearings, and decorative components.

6. Nickel-Based Alloys

For high-temperature applications, nickel alloys offer:

Superior heat and oxidation resistance.

High mechanical strength at elevated temperatures.

They are widely used in turbines, petrochemical equipment, and aerospace engines.

Performance Analysis of Casting Parts

Analyzing the performance of casting parts ensures they meet the required operational conditions. Several factors must be considered:

Mechanical Properties

Tensile strength, compressive strength, hardness, and fatigue resistance are tested to confirm durability under stress.

Thermal Performance

Heat resistance and thermal conductivity are crucial for high-temperature applications. Materials like stainless steel and nickel alloys excel here.

Corrosion Resistance

For parts exposed to moisture, chemicals, or saltwater, stainless steel and copper alloys provide long-lasting protection.

Wear Resistance

Abrasion resistance is vital in mining, construction, and heavy machinery applications. Cast iron and hardened steels are commonly chosen.

Weight-to-Strength Ratio

Lightweight materials like aluminum reduce fuel consumption in transportation without compromising strength.

Cost and Manufacturing Efficiency

The chosen material must balance performance with affordability. For example, cast iron is cost-effective, while stainless steel provides longer service life.

Applications of Casting Parts

Casting parts are found in nearly every industry:

Automotive – engine blocks, transmission housings, brake components.

Aerospace – turbine blades, structural brackets, fuel system parts.

Energy sector – pump casings, valves, power plant components.

Construction and mining – excavator parts, gears, and wear-resistant liners.

Marine – propellers, pump housings, and deck equipment.

Conclusion

The performance and longevity of casting parts heavily depend on material selection and thorough performance analysis. Choosing the right alloy ensures that parts withstand mechanical stress, resist environmental conditions, and deliver cost-effective solutions. From cast iron and steel to aluminum and advanced nickel alloys, each material brings unique benefits to suit specific industries.

By carefully evaluating material properties, operational requirements, and economic considerations, manufacturers can deliver casting parts that achieve superior strength, reliability, and efficiency in real-world applications.