Home / Resources / Blogs / Industry News / Precision Manufacturing: Key Technology to Improve the Quality of Mechanical Equipment Parts

Precision Manufacturing: Key Technology to Improve the Quality of Mechanical Equipment Parts

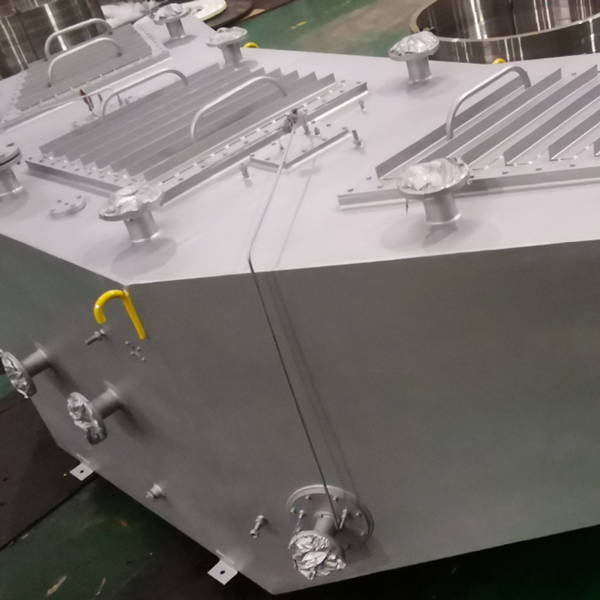

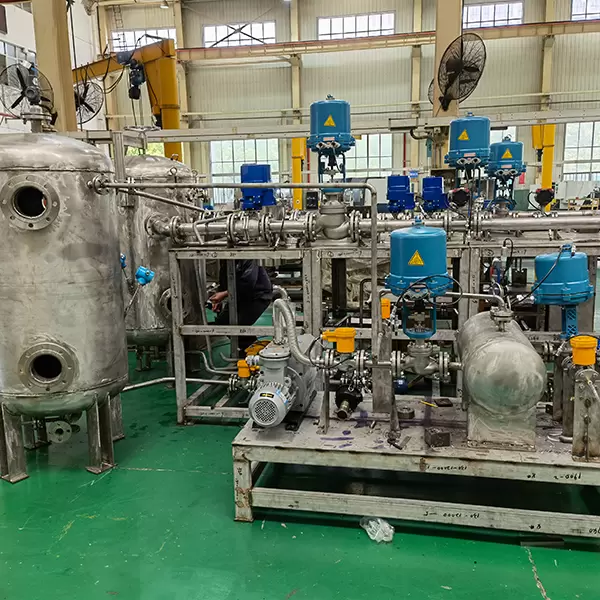

In today’s competitive industrial landscape, the quality and reliability of mechanical equipment parts are crucial to operational efficiency and product performance. Companies are increasingly investing in precision manufacturing technologies to meet high standards of accuracy, durability, and consistency.

Precision manufacturing enables the production of parts with tight tolerances, superior surface finish, and high repeatability. These qualities are essential across industries such as automotive, aerospace, electronics, energy, and heavy machinery, where even minor deviations can lead to performance issues or costly downtime.

What is Precision Manufacturing

Precision manufacturing refers to advanced production processes that ensure mechanical components are fabricated with extremely high accuracy and minimal deviation from design specifications. Unlike conventional manufacturing, which may have broader tolerances, precision manufacturing focuses on:

Tight dimensional accuracy

Consistent surface quality

Reliable material properties

High repeatability across batches

The goal is to create parts that meet exact design requirements, reduce errors, and enhance overall system performance.

Key Technologies in Precision Manufacturing

1. Computer Numerical Control (CNC) Machining

CNC machining allows manufacturers to produce parts with highly accurate dimensions using automated, computer-controlled tools. It reduces human error, improves consistency, and enables complex geometries that are difficult to achieve with traditional methods.

2. Additive Manufacturing (3D Printing)

Additive manufacturing technologies, such as selective laser sintering (SLS) and direct metal laser sintering (DMLS), create components layer by layer. This method provides high precision, rapid prototyping, and flexibility in design customization.

3. Precision Grinding and Polishing

Grinding and polishing techniques are essential for achieving smooth surface finishes and tight tolerances. These processes are widely used in gears, shafts, bearings, and other high-precision components.

4. Laser Cutting and Engraving

Laser technologies offer unmatched precision for cutting, shaping, or marking parts. They are especially valuable in industries requiring fine details, such as electronics or medical device manufacturing.

5. Coordinate Measuring Machines (CMM)

CMMs provide precise measurements of manufactured parts to ensure they meet design specifications. This quality control technology is essential for identifying deviations and maintaining consistent production standards.

6. Advanced Material Processing

Techniques like heat treatment, surface coating, and alloying enhance the durability, wear resistance, and performance of mechanical parts. These processes complement precision machining to produce high-quality components.

Advantages of Precision Manufacturing

Improved Component Performance

Parts manufactured with high precision operate smoothly and reliably, reducing the risk of breakdowns or operational inefficiencies.

Reduced Waste and Costs

Tighter tolerances mean fewer defective parts and less material waste, leading to cost savings in production and maintenance.

Enhanced Product Longevity

Precision components experience less wear and tear, extending the lifespan of mechanical systems and reducing downtime.

Ability to Manufacture Complex Designs

Advanced precision technologies allow the production of intricate parts that would be impossible with traditional methods.

Consistency Across Production Batches

High repeatability ensures that every part meets the same quality standards, which is critical for large-scale manufacturing.

Applications Across Industries

1. Automotive Industry

Precision-manufactured engine components, transmission parts, and suspension systems improve vehicle performance, fuel efficiency, and safety.

2. Aerospace and Aviation

Aircraft parts require extremely tight tolerances to ensure structural integrity and reliability in demanding environments.

3. Medical Equipment

Surgical instruments, implants, and diagnostic devices rely on precision manufacturing for accuracy, safety, and biocompatibility.

4. Energy and Power Generation

Turbines, generators, and industrial machinery require high-precision components to operate efficiently and withstand harsh conditions.

5. Electronics and Semiconductor Industry

Miniaturized components and circuit elements demand precise manufacturing to ensure functionality and reduce defects.

Challenges in Precision Manufacturing

Despite its advantages, precision manufacturing faces several challenges:

High Equipment Costs: Advanced machinery such as CNC machines and 3D printers require significant investment.

Skilled Workforce: Operating precision equipment demands trained professionals with specialized knowledge.

Material Limitations: Not all materials are suitable for extreme precision processes, requiring careful selection and preparation.

Quality Control Requirements: Maintaining tight tolerances necessitates rigorous inspection and monitoring systems.

Overcoming these challenges requires ongoing investment in technology, training, and quality assurance processes.

Conclusion

Precision manufacturing plays a pivotal role in enhancing the quality of mechanical equipment parts. By leveraging technologies such as CNC machining, additive manufacturing, precision grinding, and advanced material processing, industries can produce components with exceptional accuracy, durability, and consistency.

The advantages of precision manufacturing—including improved performance, reduced waste, extended component lifespan, and the ability to produce complex designs—make it essential for modern industrial applications. From automotive and aerospace to medical and electronics industries, adopting precision manufacturing technologies ensures that mechanical equipment meets the highest quality standards, improves operational efficiency, and maintains competitive advantage.

For more product details, please see: Mechanical Equipment Parts – Jiangxi Hongdu Preciosion Machinery