Home / Resources / Blogs / Industry News / Application of Intelligent Technology in Die Precision Machining

Application of Intelligent Technology in Die Precision Machining

In the modern manufacturing landscape, precision machining plays a crucial role in producing high-quality components for various industries, including automotive, aerospace, and electronics. The advent of intelligent technology has revolutionized die precision machining, enhancing efficiency, accuracy, and overall productivity.

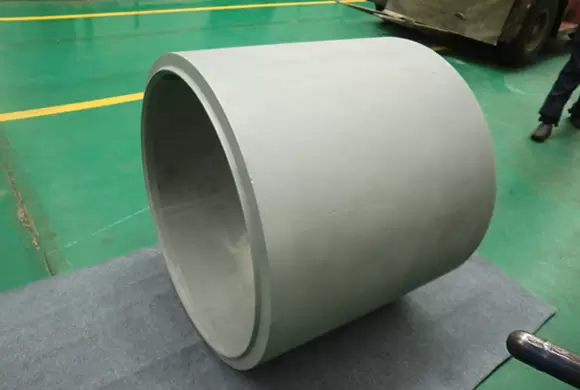

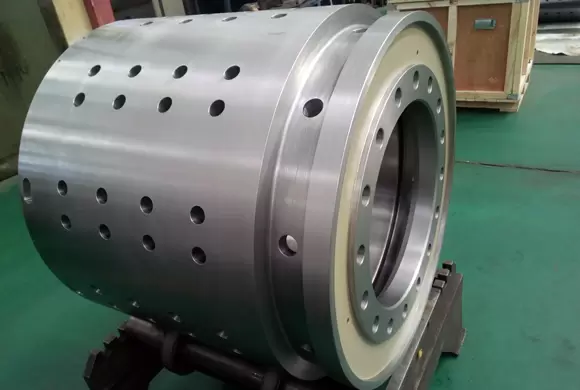

Understanding Die Precision Machining

Die precision machining involves the manufacturing of dies and molds that are used to shape materials into desired forms. This process requires high levels of accuracy and precision, as even the slightest deviation can lead to significant defects in the final product. Traditional machining methods often rely on manual input and experience, which can introduce variability and inefficiencies.

The Role of Intelligent Technology

Intelligent technology encompasses a range of advanced tools and systems, including artificial intelligence (AI), machine learning, the Internet of Things (IoT), and automation. These technologies are increasingly being integrated into die precision machining processes to enhance performance and reduce human error.

1. Automation in Machining Processes

Automation plays a pivotal role in die precision machining by streamlining operations and minimizing human intervention. Automated machines equipped with intelligent systems can perform complex tasks with high precision and speed. For instance, CNC (Computer Numerical Control) machines can be programmed to execute intricate designs, ensuring consistent quality across multiple production runs.

2. Predictive Maintenance

One of the significant advantages of intelligent technology is its ability to predict equipment failures before they occur. By utilizing IoT sensors and data analytics, manufacturers can monitor the condition of their machines in real-time. This predictive maintenance approach reduces downtime and maintenance costs, allowing for uninterrupted production and improved overall efficiency.

3. Enhanced Quality Control

Quality control is paramount in die precision machining. Intelligent technology enables manufacturers to implement advanced quality assurance systems that utilize AI algorithms to analyze data from the machining process. These systems can detect anomalies and deviations from specified tolerances, allowing for immediate corrective actions. As a result, the overall quality of the produced dies is significantly improved.

Benefits of Intelligent Technology in Die Precision Machining

The integration of intelligent technology in die precision machining offers numerous benefits:

1. Increased Efficiency

Intelligent systems can optimize machining processes by analyzing data and adjusting parameters in real-time. This leads to reduced cycle times and increased throughput, allowing manufacturers to meet growing demand without compromising quality.

2. Cost Reduction

By minimizing waste, reducing rework, and optimizing resource utilization, intelligent technology can significantly lower production costs. Predictive maintenance also contributes to cost savings by preventing unexpected breakdowns and extending the lifespan of machinery.

3. Improved Precision

The use of advanced algorithms and automation ensures that machining processes are executed with a high degree of accuracy. This precision is critical in industries where tolerances are tight, and even minor deviations can result in substantial financial losses.

Challenges in Implementing Intelligent Technology

Despite the numerous advantages, the implementation of intelligent technology in die precision machining is not without challenges:

1. High Initial Investment

The integration of intelligent systems often requires significant upfront investment in technology and training. Smaller manufacturers may find it challenging to allocate the necessary resources, which can hinder their ability to compete in the market.

2. Skill Gap

The adoption of intelligent technology necessitates a workforce skilled in operating and maintaining advanced machinery and software. There is often a skill gap in the labor market, making it difficult for manufacturers to find qualified personnel.

3. Data Security Concerns

As manufacturing processes become increasingly connected through IoT devices, data security becomes a critical concern. Manufacturers must implement robust cybersecurity measures to protect sensitive information and prevent potential breaches.

Future Prospects

The future of die precision machining is undoubtedly intertwined with the continued advancement of intelligent technology. As AI and machine learning algorithms become more sophisticated, we can expect even greater levels of automation and efficiency. Additionally, the development of collaborative robots (cobots) that can work alongside human operators will further enhance productivity and safety in machining environments.

Conclusion

The application of intelligent technology in die precision machining is transforming the manufacturing landscape. By leveraging automation, predictive maintenance, and enhanced quality control, manufacturers can achieve unprecedented levels of efficiency and precision. While challenges remain, the benefits of adopting intelligent technology far outweigh the drawbacks. As the industry continues to evolve, embracing these advancements will be essential for staying competitive in a rapidly changing market.