Home / Resources / Blogs / Industry News / Precision in Motion: How Custom Parts for Mechanical Equipment Drive Industrial Excellence

Precision in Motion: How Custom Parts for Mechanical Equipment Drive Industrial Excellence

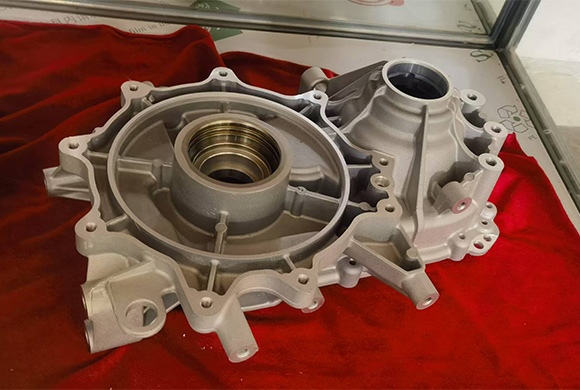

In the age of automation and advanced manufacturing, precision is the foundation of reliability and performance. Every piece of machinery, whether in aerospace, automotive, energy, or heavy industry, relies on meticulously designed and fabricated components that ensure smooth, efficient, and long-lasting operation. Custom parts for mechanical equipment play a crucial role in achieving these standards—tailored to meet unique technical requirements, operating conditions, and performance goals.

Jiangxi Hongdu Precision Machinery, a leader in mechanical component design and manufacturing, has been at the forefront of this customization revolution. With advanced engineering capabilities and a deep understanding of material science and process optimization, Jiangxi Hongdu provides bespoke solutions that power everything from industrial automation systems to high-precision motion equipment.

Why Custom Parts Matter in Mechanical Engineering

Every mechanical system is only as strong as its weakest component. Standardized or off-the-shelf parts, while convenient, often fail to meet the specific operational demands of modern equipment—particularly in sectors that demand extreme precision, efficiency, or environmental resistance.

Custom mechanical parts offer several critical advantages:

Enhanced Performance:

Tailored components optimize power transmission, reduce friction, and ensure alignment across assemblies. This precision leads to better mechanical efficiency, reduced wear, and lower maintenance costs.

Design Flexibility:

Engineers can design custom parts that integrate seamlessly into existing systems, accommodating unique dimensions, tolerances, and material requirements that standard parts simply cannot offer.

Improved Reliability and Lifespan:

Custom-engineered components are built with specific environmental and load conditions in mind, improving resistance to stress, corrosion, and fatigue—key factors for long-term reliability.

Cost Efficiency Over Time:

While the initial investment in custom manufacturing may be higher, the resulting reduction in downtime, replacements, and maintenance often leads to lower total cost of ownership.

The Engineering Behind Custom Parts

Developing custom parts for mechanical equipment is a sophisticated process that merges design innovation, computational simulation, and precision manufacturing.

At Jiangxi Hongdu Precision Machinery, this process involves several key stages:

Concept and Design Phase:

Engineers collaborate with clients to understand specific mechanical and operational requirements. 3D CAD modeling and finite element analysis (FEA) are used to predict performance and optimize geometry before fabrication.

Material Selection:

Depending on the application—be it high torque, heat resistance, or corrosive environments—materials are selected from a wide range, including carbon steel, stainless steel, titanium, and engineered alloys.

Precision Machining and Fabrication:

Utilizing CNC machining, laser cutting, and high-tolerance grinding, Hongdu ensures each part achieves micron-level accuracy. Advanced surface treatments such as anodizing, nitriding, or PVD coating further enhance durability.

Quality Control and Testing:

Every custom part undergoes rigorous inspection using coordinate measuring machines (CMM), ultrasonic testing, and fatigue analysis to ensure it meets exacting performance and safety standards.

Applications Across Industries

Custom mechanical parts are integral to a wide range of industries, each with distinct performance demands:

Aerospace & Defense: High-strength, lightweight components for engines, landing gears, and flight control systems.

Automotive Manufacturing: Precision gears, shafts, and housings for drivetrains and hybrid power systems.

Energy & Power Generation: Turbine blades, valve assemblies, and custom seals designed to withstand extreme temperatures and pressures.

Industrial Automation: Actuator components, linear motion systems, and robotics parts that require precise repeatability and alignment.

Medical Equipment: Surgical devices and diagnostic machinery rely on exact tolerances to ensure accuracy and patient safety.

Through innovation and precision, Jiangxi Hongdu Precision Machinery continues to deliver reliable solutions that push the boundaries of mechanical performance in all these fields.

Why Choose Jiangxi Hongdu Precision Machinery

With decades of experience, Jiangxi Hongdu Precision Machinery has earned a reputation for technical excellence and customer-focused engineering. The company’s strengths include:

Advanced Production Facilities: Equipped with high-precision CNC systems and multi-axis machining centers.

Experienced Engineering Team: Specialists in mechanical design, material science, and process optimization.

Comprehensive Quality Assurance: ISO-certified processes that guarantee performance consistency.

Global Partnerships: Serving clients across diverse industries worldwide with rapid delivery and responsive support.

When it comes to custom parts for mechanical equipment, Jiangxi Hongdu stands as a trusted partner for industries seeking precision, durability, and engineering innovation.

Conclusion: Tailored Engineering for a Smarter Future

The future of mechanical engineering lies in customization and precision. As automation and advanced systems demand greater accuracy and reliability, the role of custom parts for mechanical equipment becomes increasingly critical.

Jiangxi Hongdu Precision Machinery continues to shape this future through its unwavering commitment to innovation, quality, and precision craftsmanship—ensuring that every component it delivers performs flawlessly under the toughest industrial conditions.

For more product details, please see: Custom Parts for Mechanical Equipment – Jiangxi Hongdu Preciosion Machinery