Home / Resources / Blogs / Industry News / Precision Ignition: How Elevates Performance with High-Quality Car Distributor Parts

Precision Ignition: How Elevates Performance with High-Quality Car Distributor Parts

In the world of automotive engineering, precision and reliability are non-negotiable. Every component of a vehicle’s ignition system plays a critical role in ensuring smooth engine performance, optimal combustion, and long-term durability. Among these components, car distributor parts stand as one of the most vital assemblies for maintaining precise ignition timing and stable power delivery.

As automotive technology advances, so does the need for components that combine mechanical accuracy with material excellence. Jiangxi Hongdu Precision Machinery, a trusted name in automotive manufacturing, has established itself as a leading supplier of high-performance car distributor parts engineered to meet the exacting standards of modern vehicles. Through innovation, rigorous quality control, and advanced manufacturing, the company delivers parts that ensure engines fire with flawless precision every time.

Understanding the Role of Car Distributor Parts

A car distributor is the central component of a vehicle’s ignition system (in traditional gasoline engines). Its job is to distribute high-voltage current from the ignition coil to the spark plugs in the correct firing order and timing sequence. This process ensures that the air-fuel mixture inside each cylinder ignites at the optimal moment for efficient combustion.

The car distributor parts that make up this system include:

Distributor Cap: Houses terminals that connect to spark plug wires and protect internal components from contaminants.

Distributor Shaft: Connects to the engine’s camshaft to synchronize spark timing with engine cycles.

Breaker Points or Ignition Module: Controls the timing of the current interruption in traditional and electronic ignition systems.

Vacuum and Mechanical Advance Mechanisms: Adjust ignition timing dynamically based on engine load and speed.

Each part must be manufactured to tight tolerances, as even minute deviations can result in misfiring, poor fuel economy, or power loss.

Engineering Precision from Jiangxi Hongdu Precision Machinery

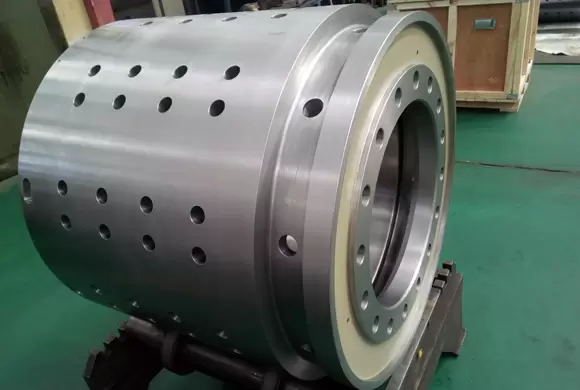

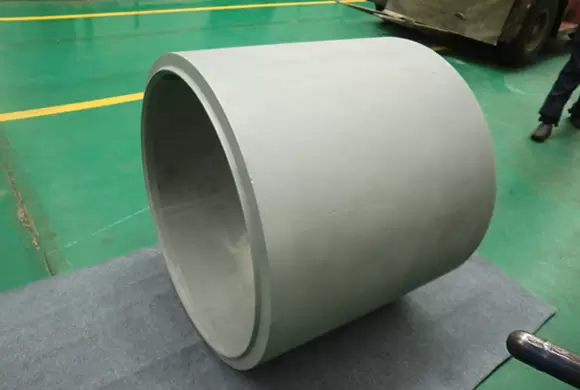

What sets Jiangxi Hongdu Precision Machinery apart is its unwavering dedication to dimensional accuracy, material performance, and reliability under extreme conditions. Every car distributor component produced by the company undergoes a series of precision machining, surface treatment, and testing procedures to ensure long-term operational stability.

1. Advanced Materials for Enhanced Durability

The performance of distributor components depends heavily on material selection. Jiangxi Hongdu uses heat-resistant polymers, high-grade aluminum alloys, and treated steel to ensure the distributor cap, rotor, and shaft withstand high temperatures, vibration, and corrosive environments.

2. Micron-Level Machining Precision

Using CNC machining centers and automated assembly systems, the company achieves micron-level accuracy in part dimensions. This ensures that each rotor and shaft aligns perfectly with the ignition system’s geometry, reducing wear and guaranteeing stable performance.

3. Strict Quality Control and Testing

Every batch of car distributor parts undergoes dynamic balance testing, electrical conductivity verification, and high-temperature endurance assessments. By simulating real-world engine conditions, Jiangxi Hongdu ensures its components deliver consistent ignition performance across thousands of operating hours.

Why High-Quality Car Distributor Parts Matter

In the era of advanced automotive engines, ignition precision directly affects engine performance, emissions, and fuel economy. Using substandard distributor components can cause serious operational issues such as:

Irregular Ignition Timing: Leading to engine knocking or misfires.

Reduced Fuel Efficiency: Due to incomplete combustion.

Starting Difficulties: Especially in cold or humid environments.

Shortened Engine Life: Caused by prolonged detonation or poor combustion control.

By contrast, high-quality distributor parts—such as those produced by Jiangxi Hongdu Precision Machinery—ensure:

Accurate and consistent spark timing for optimal power output.

Extended component life through superior materials and craftsmanship.

Enhanced ignition efficiency, contributing to lower emissions.

Improved reliability under variable load and speed conditions.

These advantages make Jiangxi Hongdu’s products the preferred choice for both OEMs and high-performance aftermarket applications.

Conclusion

The performance of an engine begins with ignition—and ignition depends on precision. Jiangxi Hongdu Precision Machinery has built its reputation on delivering high-quality car distributor parts that embody durability, accuracy, and innovation.

Through state-of-the-art manufacturing, stringent quality control, and a deep understanding of ignition dynamics, Jiangxi Hongdu helps ensure engines perform efficiently, reliably, and cleanly. Whether supporting OEM production lines or serving the aftermarket, the company continues to set new benchmarks in the field of automotive precision engineering.