Home / Resources / Blogs / Industry News / Durable and Accurate Custom Machined Shaft Parts for Complex Equipment

Durable and Accurate Custom Machined Shaft Parts for Complex Equipment

In modern industrial and mechanical applications, precision and reliability are critical for optimal performance. Shafts serve as fundamental components in a wide range of machinery, from automotive engines to industrial gear systems. Custom machining of shaft parts ensures that these essential components meet exact specifications, withstand demanding operating conditions, and deliver long-lasting performance. By combining advanced manufacturing technologies with rigorous quality control, manufacturers can produce durable, accurate, and tailored shaft components suitable for complex equipment.

What is Custom Machining of Shaft Parts

Custom machining of shaft parts involves producing shafts according to specific dimensions, tolerances, and functional requirements. Unlike standard off-the-shelf components, custom machined shafts are designed to meet the unique needs of individual machines or assemblies. This process typically utilizes advanced CNC turning, milling, grinding, and heat treatment techniques to achieve high precision, superior surface finish, and structural integrity.

Custom machining is particularly essential in industries where even minor deviations in shaft dimensions can result in operational inefficiencies, premature wear, or equipment failure.

Key Features of Custom Machined Shaft Parts

Precision Engineering

Utilizing computer-controlled machining tools ensures that every shaft part meets exact tolerances. Precision engineering minimizes vibration, enhances rotational stability, and improves overall equipment efficiency.

High Durability

Custom shafts are typically manufactured from high-grade materials such as stainless steel, alloy steel, or heat-treated metals, providing superior resistance to wear, fatigue, and corrosion. This ensures reliable performance in demanding industrial environments.

Tailored Design

Custom machining allows for flexible designs, including complex geometries, specific diameter variations, keyways, splines, threads, or surface finishes. Tailored shafts can be engineered to integrate seamlessly with other machine components.

Surface Finish and Coatings

Advanced machining techniques deliver smooth surface finishes, reducing friction and wear during operation. Additional surface treatments or coatings, such as nitriding or electroplating, enhance durability and corrosion resistance.

Compatibility with Complex Equipment

Custom machined shafts are engineered to fit specific machines, ranging from high-speed motors and pumps to industrial gearboxes and robotics. This compatibility ensures optimal performance and longevity of the overall system.

Applications of Custom Machined Shaft Parts

Automotive Industry: Precision shafts for engines, transmissions, and drive systems.

Aerospace: High-strength shafts for turbines, actuators, and control mechanisms.

Industrial Machinery: Shafts for gearboxes, pumps, conveyor systems, and CNC machines.

Robotics and Automation: Custom shafts for precision motion control and robotic arms.

Marine and Energy: Shafts for propulsion systems, turbines, and power generation equipment.

Advantages of Choosing Custom Machined Shaft Parts

Enhanced Performance

Precisely machined shafts reduce mechanical losses, improve rotational efficiency, and support smooth operation in complex machinery.

Reduced Downtime

High-quality, durable shafts decrease the frequency of replacements or repairs, minimizing equipment downtime and maintenance costs.

Cost-Effectiveness

Although custom machining may involve higher initial investment than standard parts, the long-term benefits include lower operational costs, longer service life, and enhanced system reliability.

Flexibility for Unique Requirements

Custom machining allows for design modifications to meet specialized applications, material requirements, or operational conditions that standard shafts cannot accommodate.

Compliance with Industry Standards

Manufacturers ensure that custom machined shafts meet relevant international standards for mechanical performance, safety, and material quality, which is crucial in regulated industries.

Manufacturing Process of Custom Machined Shaft Parts

Material Selection – Choosing the appropriate metal or alloy based on load, wear resistance, and environmental conditions.

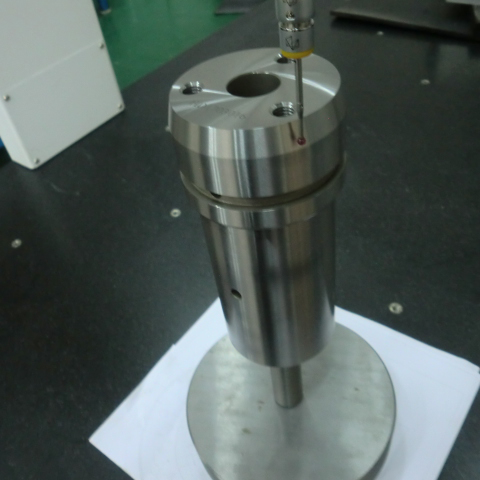

CNC Machining – Precision turning, milling, and grinding to achieve exact dimensions and tolerances.

Heat Treatment – Enhancing hardness, strength, and fatigue resistance.

Surface Finishing – Polishing, coating, or plating to improve wear and corrosion resistance.

Quality Inspection – Using advanced measuring systems to verify dimensions, concentricity, and surface quality.

This combination of careful material selection, precision machining, and thorough quality control ensures that custom shafts deliver optimal performance under demanding conditions.

Conclusion

Durable and Accurate Custom Machined Shaft Parts for Complex Equipment are essential for maintaining high-performance, reliable, and efficient machinery. By leveraging advanced CNC machining, high-quality materials, and rigorous quality control, manufacturers can produce shafts that meet the exact requirements of modern industrial, automotive, aerospace, and specialized equipment applications.

Investing in custom machined shaft parts not only enhances operational efficiency but also extends equipment life, reduces maintenance costs, and ensures safe and reliable performance. For industries seeking precision and durability, custom machining provides a tailored solution that standard components simply cannot match.