Home / Resources / Blogs / Industry News / Industrial-Grade Stainless Steel Ring Forging – Strength, Durability, and Precision

Industrial-Grade Stainless Steel Ring Forging – Strength, Durability, and Precision

In modern industries, the demand for high-strength and reliable metal components has never been greater. From energy and power generation to heavy machinery, aerospace, and construction, every sector requires materials that deliver durability, performance, and precision. Among the most sought-after solutions is stainless steel ring forging, a process that combines advanced metallurgy with precision machining to produce components that withstand extreme conditions while maintaining dimensional accuracy.

What Is Stainless Steel Ring Forging

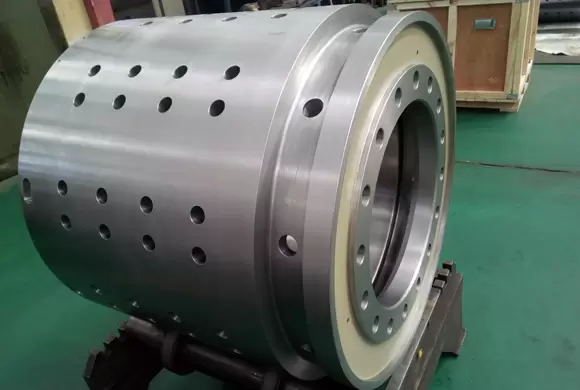

Stainless steel ring forging is a specialized manufacturing process that shapes stainless steel into seamless ring structures. Unlike casting, forging refines the internal grain structure of the metal, eliminating defects and significantly improving mechanical properties. Through controlled deformation at high temperatures, forged stainless steel rings achieve outstanding toughness, resistance to fatigue, and superior structural integrity.

When paired with precision machining, the forged rings are tailored to exact dimensions and surface finishes, ensuring they meet the strict requirements of industrial applications. This synergy between forging and machining ensures both strength and precision, making forged stainless steel rings an essential choice across industries.

Key Advantages of Stainless Steel Ring Forging

Unmatched Strength and Durability

Forging compresses and aligns the metal’s grain structure, resulting in higher tensile strength and resistance to impact compared to cast or welded alternatives. This ensures the rings can withstand heavy loads and extreme operating environments.

Superior Corrosion Resistance

Stainless steel is inherently resistant to corrosion, oxidation, and chemical attack. When forged, its resistance is further enhanced, making stainless steel ring forgings ideal for applications in marine, oil and gas, and chemical processing industries.

Dimensional Accuracy with Precision Machining

After forging, advanced CNC machining is applied to achieve strict tolerances and smooth finishes. This allows the rings to be integrated seamlessly into complex assemblies, reducing installation challenges.

Fatigue and Wear Resistance

Stainless steel ring forgings provide excellent resistance to cyclic stress and wear, which is crucial for components exposed to continuous motion or vibration.

Versatility in Size and Design

From small rings used in pumps and valves to large-scale forged rings for wind turbines or aerospace applications, the process supports a wide range of dimensions and customization.

Applications of Industrial-Grade Stainless Steel Ring Forging

The reliability of stainless steel forged rings makes them indispensable across industries:

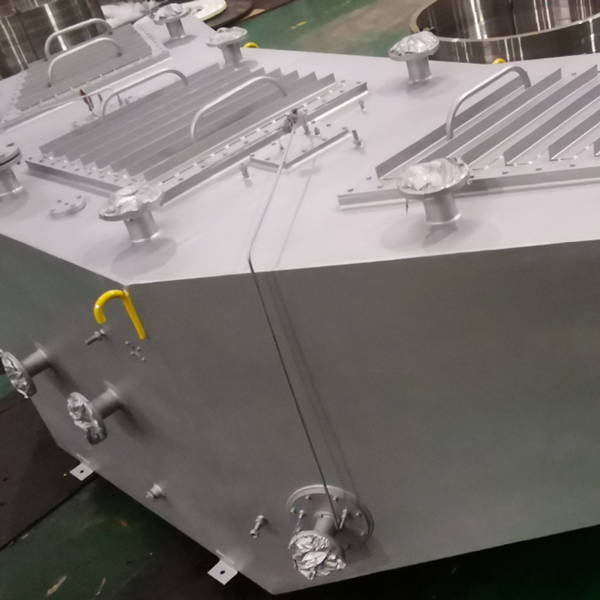

Energy and Power Generation: Used in turbines, generators, and nuclear reactors where high strength and corrosion resistance are critical.

Aerospace and Aviation: Precision-forged rings are essential in jet engines and landing gear systems, where performance under stress is non-negotiable.

Marine and Offshore Engineering: Forged stainless steel rings withstand the harshest saltwater environments, ensuring long service life in ships and oil rigs.

Automotive and Heavy Machinery: Rings are used in drive systems, gear assemblies, and high-load machinery, providing reliability and extended operational life.

Construction and Infrastructure: Forged stainless steel components support bridges, tunnels, and large-scale structural frameworks.

Precision Machining for Superior Performance

While forging establishes strength and resilience, precision machining transforms forged stainless steel rings into finished components ready for demanding applications. Using state-of-the-art CNC lathes, milling machines, and grinding systems, manufacturers achieve exact tolerances, optimal surface roughness, and customized geometries.

This combination ensures that every stainless steel ring not only meets but exceeds the required performance standards, enhancing efficiency and safety in end-use environments.

Why Choose Industrial-Grade Stainless Steel Ring Forging

Reliability: Forged stainless steel rings deliver consistent performance under extreme mechanical and environmental conditions.

Cost-Effectiveness: The extended lifespan of forged rings reduces replacement costs and downtime.

Sustainability: Stainless steel is fully recyclable, and forging produces less waste compared to other manufacturing methods.

Customization: Tailored solutions for specific industries and projects, ensuring every component fits perfectly into its application.

Conclusion

Industrial-grade stainless steel ring forging represents the perfect blend of strength, durability, and precision. By combining advanced forging technology with precision machining, manufacturers provide components that meet the strictest performance and safety requirements across diverse industries. Whether it’s aerospace engineering, offshore platforms, or heavy machinery, stainless steel forged rings ensure reliability and long-term value.

As industries continue to evolve and demand higher-performance materials, stainless steel ring forging will remain a cornerstone in the development of robust, efficient, and sustainable solutions.