Home / Resources / Blogs / Industry News / Optimization of Large Tube Part Design for Enhanced Service Life in Heavy-Duty Mining Operations

Optimization of Large Tube Part Design for Enhanced Service Life in Heavy-Duty Mining Operations

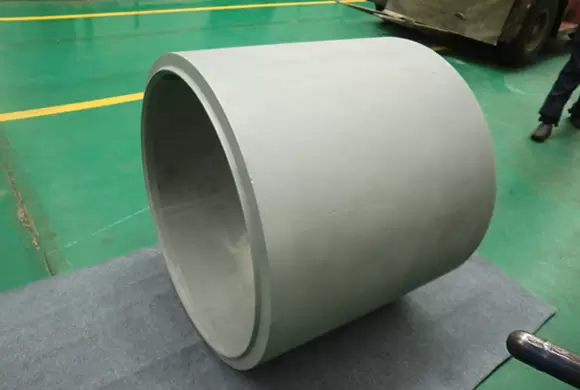

In the mining industry, equipment durability and operational reliability are critical to productivity and cost efficiency. One of the most essential components in heavy-duty mining machinery is the large tube part. These structural elements play a crucial role in supporting heavy loads, withstanding extreme working conditions, and ensuring the stability of the equipment.

Our advanced approach to designing and manufacturing mining machinery large tube parts focuses on maximizing service life, improving strength, and minimizing deformation through precise engineering and innovative production techniques.

Material Selection: Carbon Steel Plate for Superior Strength

The foundation of any high-performance large tube part lies in its material. We utilize high-quality carbon steel plate to ensure excellent strength, wear resistance, and structural integrity.

Key benefits of carbon steel plate in mining machinery large tube parts include:

High Load-Bearing Capacity – Capable of supporting heavy dynamic loads in demanding mining environments.

Excellent Weldability – Ensuring strong, uniform joints during fabrication.

Enhanced Toughness – Minimizing the risk of cracking or failure under stress.

The carbon steel plates we use can be coiled to a maximum thickness of 300 mm, making them ideal for manufacturing oversized tube parts that can handle extreme mechanical forces.

Precision Manufacturing with Thick Coiled Plates

Producing large tube parts from plates up to 300 mm thick presents unique challenges in forming and fabrication. Our manufacturing process leverages advanced rolling, welding, and machining techniques to achieve precise dimensions and uniform wall thickness.

By using state-of-the-art coiling equipment, we can create large-diameter tubes with perfect roundness, which is crucial for minimizing stress concentrations and ensuring smooth operation under heavy loads.

Heat Treatment for Deformation Control

Large tube parts in mining machinery are exposed to significant thermal and mechanical stresses during operation. Without proper treatment, these stresses can lead to warping, dimensional changes, or premature wear.

Our controlled heat treatment process offers the following advantages:

Stress Relief – Eliminates residual stresses from forming and welding.

Dimensional Stability – Effectively controls deformation even under heavy operating loads.

Improved Microstructure – Enhances hardness and strength for extended service life.

This ensures that every large tube part maintains its precise geometry and performance standards throughout its operational lifespan.

Optimized Structural Design

The design phase is critical to the performance of mining machinery large tube parts. Our engineering team employs advanced simulation tools to optimize wall thickness, reinforcement placement, and geometry for maximum load distribution.

We analyze key factors such as:

Load Path Efficiency – Reducing stress concentrations at critical points.

Vibration Resistance – Improving fatigue performance under repetitive loading.

Weight Optimization – Balancing strength with manageable component weight for easier installation.

Through design optimization, we extend the service life of each component while minimizing maintenance requirements.

Applications in Heavy-Duty Mining Operations

Our large tube parts are widely used in various types of mining machinery, including:

Excavators and Shovels – Structural arms and boom supports.

Conveyor Systems – Heavy-duty rollers and support frames.

Drilling Equipment – Rotating and stationary structural tubes.

Haul Trucks and Loaders – Frame reinforcements and pivot joints.

In each application, the mining machinery large tube part must deliver exceptional performance under harsh conditions such as high impact forces, abrasive materials, and extreme temperatures.

Quality Control and Testing

To ensure every large tube part meets strict performance requirements, we implement rigorous quality control procedures:

Ultrasonic Testing (UT) – To detect any internal flaws in thick plates.

Dimensional Inspection – Ensuring exact tolerances are maintained.

Mechanical Testing – Verifying strength, hardness, and impact resistance.

Only components that pass all tests are shipped to our clients, guaranteeing reliable performance in the field.

Conclusion

The optimization of mining machinery large tube part design is not just about making components stronger—it’s about improving efficiency, reducing downtime, and maximizing return on investment for mining operations.

By combining carbon steel plate materials, plate thickness up to 300 mm, precision coiling, and heat treatment for deformation control, we deliver large tube parts that stand up to the toughest conditions and extend the operational life of mining equipment.