Home / Resources / Blogs / Industry News / Precision Engineered Non-Metallic Parts for High-Performance Machinery

Precision Engineered Non-Metallic Parts for High-Performance Machinery

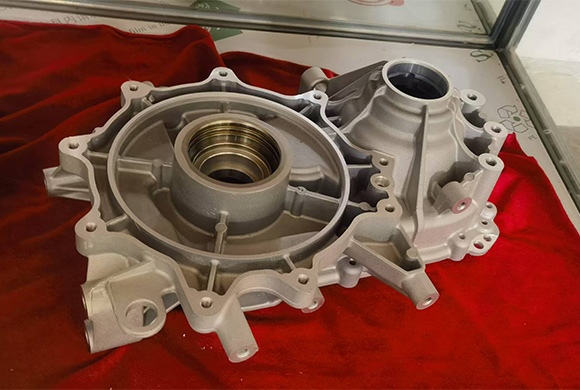

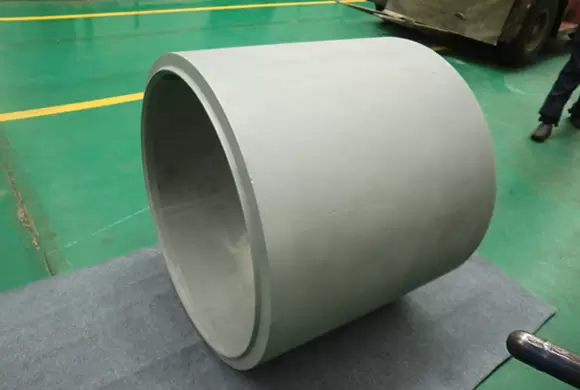

In the modern industrial and manufacturing sectors, machinery efficiency, reliability, and durability are critical factors that determine overall productivity. One essential component in achieving these goals is the use of precision engineered non-metallic parts. Unlike traditional metallic components, non-metallic parts offer unique advantages such as corrosion resistance, lightweight design, and reduced maintenance requirements, making them ideal for high-performance machinery across a variety of industries.

Why Choose Non-Metallic Parts?

Non-metallic parts are manufactured from advanced polymers, composites, ceramics, and other engineered materials to provide superior performance under demanding conditions. The growing adoption of these components is driven by several advantages:

Corrosion and Chemical Resistance – Non-metallic materials do not rust or corrode, making them suitable for harsh industrial environments.

Lightweight Design – Reduces the overall weight of machinery, improving energy efficiency and reducing operational costs.

Noise Reduction – Many non-metallic components absorb vibrations and reduce mechanical noise during operation.

Durability and Wear Resistance – Engineered non-metallic parts offer high strength and longevity, even under heavy loads.

Electrical Insulation – Certain non-metallic materials provide excellent insulating properties, enhancing machine safety.

By integrating these parts, manufacturers can significantly improve machine performance, lower maintenance costs, and extend operational life.

Key Features of Precision Engineered Non-Metallic Parts

1. High Precision and Accuracy

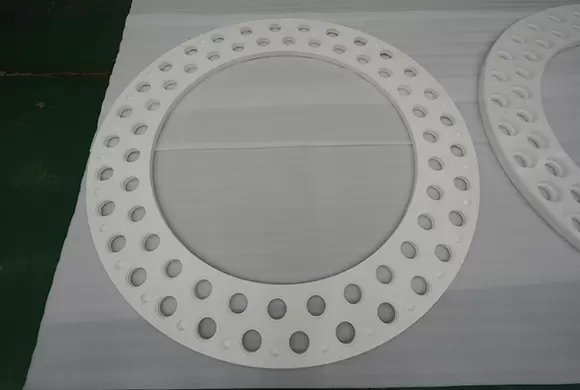

These parts are designed and manufactured with tight tolerances to ensure perfect fit and function within complex machinery. Advanced CNC machining, molding, and additive manufacturing techniques allow for consistent quality and precise dimensions.

2. Superior Material Selection

Precision engineered non-metallic parts are crafted from high-performance materials such as polyurethane, PTFE, PEEK, nylon, and fiberglass composites. Each material is chosen for its specific properties, ensuring optimal performance in applications ranging from automotive to aerospace.

3. Resistance to Wear and Tear

Non-metallic parts are often designed to reduce friction and withstand repetitive motion, which extends their service life compared to conventional metal components. This makes them particularly effective in gears, bearings, seals, and conveyor system parts.

4. Lightweight and Energy-Efficient

The reduced weight of non-metallic components contributes to lower energy consumption and improved overall machinery efficiency. This is especially beneficial for moving parts and high-speed machinery where reducing inertia and load is critical.

5. Environmentally Friendly Options

Many non-metallic materials can be produced with recycled content or through eco-conscious manufacturing processes, aligning with global sustainability initiatives and corporate social responsibility goals.

Applications of Non-Metallic Parts in High-Performance Machinery

The versatility of precision engineered non-metallic parts allows them to be utilized across a wide range of industries and applications:

Automotive Industry – Lightweight gears, bushings, seals, and insulation components for cars and trucks.

Industrial Machinery – Conveyor belts, rollers, and bearings that reduce wear and maintenance.

Aerospace – High-performance composite parts that withstand extreme temperatures and stresses.

Medical Equipment – Non-metallic components for sterilizable and corrosion-resistant medical devices.

Electronics and Electrical Systems – Insulators, spacers, and protective housings.

Food and Beverage Processing – FDA-approved materials for hygienic and corrosion-free machinery components.

By providing reliable performance under diverse operational conditions, these parts ensure minimal downtime and maximum productivity.

Conclusion

The adoption of precision engineered non-metallic parts for high-performance machinery provides an innovative solution to modern industrial challenges. Offering advantages such as corrosion resistance, lightweight design, durability, and reduced maintenance, these components enhance machinery efficiency, operational reliability, and long-term cost-effectiveness.

Whether in automotive, aerospace, industrial, or medical applications, non-metallic parts enable manufacturers to achieve higher productivity, improved safety, and sustainable operations. Investing in precision engineered non-metallic components ensures that high-performance machinery operates at peak efficiency while meeting the demands of today’s competitive industrial landscape.