Home / Resources / Blogs / Industry News / Redefining Durability and Precision Through the Bearing Manufacturing Process

Redefining Durability and Precision Through the Bearing Manufacturing Process

In today’s world of advanced machinery and high-speed performance, bearings are the unsung heroes that keep industries moving efficiently. Every rotation, motion, and mechanical interaction depends on these small yet powerful components. The secret behind their long-lasting reliability and precision lies in one crucial factor — the bearing manufacturing process.

At Jiangxi Hongdu Precision Machinery, we have mastered the art and science of producing high-quality bearings that deliver exceptional performance across industries. By integrating advanced technology, strict quality control, and innovative design, we have elevated the bearing manufacturing process into a model of engineering excellence and durability.

1. Understanding the Bearing Manufacturing Process

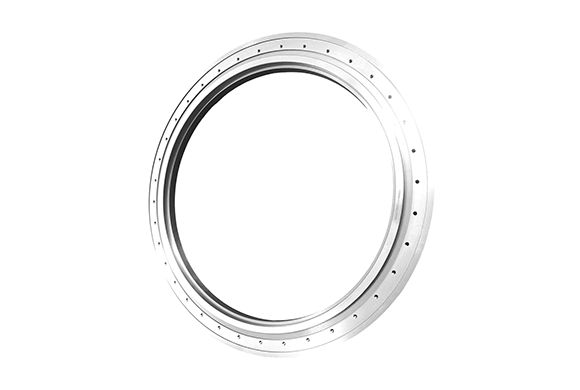

The bearing manufacturing process involves multiple stages — from material selection and forging to grinding, assembly, and quality inspection. Each step requires precision, consistency, and attention to microscopic details.

At Jiangxi Hongdu Precision Machinery, our process begins with selecting premium raw materials, typically high-carbon chromium steel or specialized alloys. These materials undergo stringent chemical and mechanical tests to ensure purity, hardness, and wear resistance. Once approved, the production journey begins:

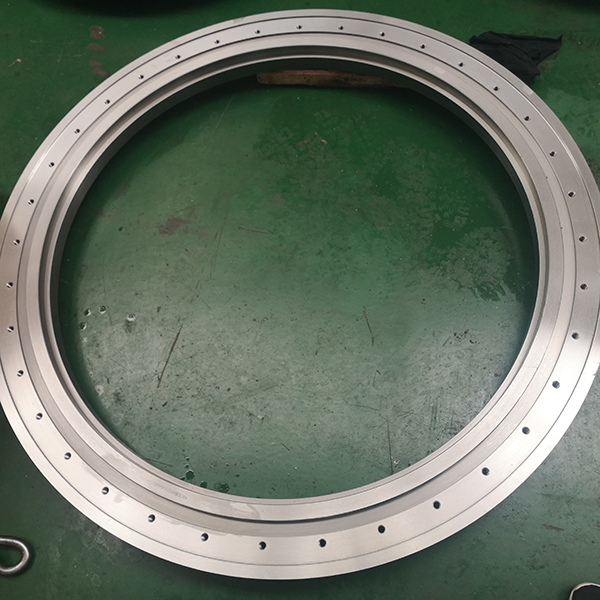

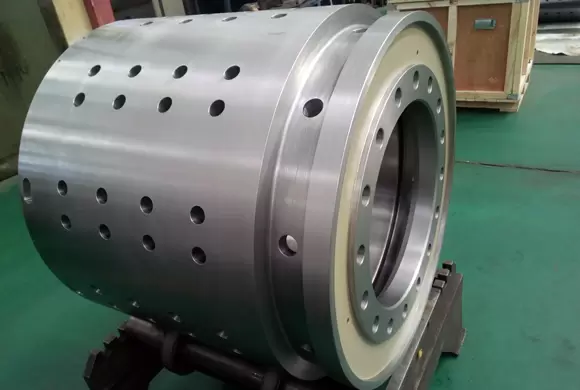

Forging and Turning: Raw steel bars are heated and forged into bearing blanks, then turned into rings with exact dimensional accuracy.

Heat Treatment: Rings undergo heat treatment to improve hardness and fatigue resistance, ensuring they withstand years of continuous operation.

Grinding and Superfinishing: Inner and outer rings are ground to microscopic tolerances, achieving mirror-like surfaces that minimize friction and noise.

Assembly: Balls or rollers are precisely positioned within the rings, and cages are added to maintain perfect spacing and movement.

Inspection and Testing: Every bearing is measured, tested, and validated under simulated working conditions before shipment.

This meticulous process guarantees that each bearing performs flawlessly under the most demanding applications.

2. The Role of Precision in Bearing Production

Precision is the heart of the bearing manufacturing process. Even the smallest deviation — a few microns — can significantly impact performance and longevity. That’s why Jiangxi Hongdu Precision Machinery employs CNC-controlled equipment, automated grinding systems, and laser measurement tools to ensure every dimension meets international standards such as ISO and ABEC ratings.

By maintaining tight control over tolerances, we ensure that our bearings deliver:

Low Friction Coefficients for efficient power transmission.

Consistent Load Distribution for extended lifespan.

Reduced Noise and Vibration for smoother operation.

Superior Rotational Accuracy for high-speed performance.

Every bearing that leaves our facility reflects our dedication to precision engineering and reliability.

3. Advanced Technology Behind Jiangxi Hongdu Bearings

At Jiangxi Hongdu Precision Machinery, innovation drives everything we do. We continuously invest in automation, robotics, and digital monitoring systems that enhance every phase of the bearing manufacturing process.

Automated Production Lines: Reduce human error and maintain uniform quality across large batches.

AI-Based Quality Control: Real-time sensors detect surface imperfections and dimensional deviations instantly.

Cleanroom Assembly Environments: Prevent contamination and extend bearing service life.

Environmentally Friendly Processes: We optimize heat treatment and lubrication systems to minimize energy use and waste.

These technological advancements not only improve manufacturing precision but also support sustainable production practices — aligning performance with environmental responsibility.

4. Quality Assurance: The Hallmark of Jiangxi Hongdu

For Jiangxi Hongdu Precision Machinery, quality isn’t an afterthought — it’s built into every stage of the bearing manufacturing process. Our in-house laboratories perform advanced testing such as:

Metallurgical Analysis to ensure material consistency.

Dynamic Load Testing to simulate real-world operating conditions.

Vibration and Noise Evaluation for quiet performance.

Dimensional Accuracy Checks using coordinate measuring machines (CMMs).

Each bearing must meet our strict internal standards before being approved for delivery. This commitment to excellence ensures our customers receive products that perform reliably in critical applications, from industrial machinery to automotive systems.

5. Applications of High-Quality Bearings

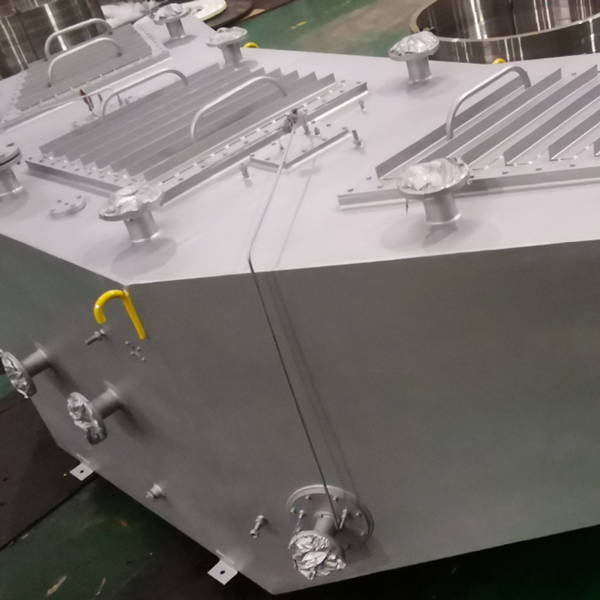

Thanks to our rigorous bearing manufacturing process, Jiangxi Hongdu bearings are trusted in industries where precision and durability are non-negotiable:

Automotive: Engine components, transmissions, and wheel hubs.

Aerospace: High-speed turbines and navigation systems.

Industrial Machinery: Pumps, motors, compressors, and conveyors.

Energy Sector: Wind turbines and power generation equipment.

Railway and Marine: Heavy-duty machinery requiring long service life and shock resistance.

Wherever motion exists, Jiangxi Hongdu bearings provide the support, stability, and reliability required for smooth, efficient operation.

Conclusion

The bearing manufacturing process is far more than a sequence of mechanical steps — it is a precise, high-tech operation that defines the quality and reliability of countless machines worldwide. At Jiangxi Hongdu Precision Machinery, we are proud to push the boundaries of engineering excellence, ensuring every bearing we produce embodies our core values of durability, precision, and performance.

Through continuous innovation and a commitment to quality, we are not only manufacturing bearings — we are shaping the future of motion technology.

If you demand superior performance, consistency, and reliability, choose Jiangxi Hongdu Precision Machinery — where every bearing tells a story of precision perfected.