Home / Resources / Blogs / Industry News / Forging the Future: How Aluminum Forgings Are Transforming Modern Manufacturing

Forging the Future: How Aluminum Forgings Are Transforming Modern Manufacturing

Aluminum forgings have become indispensable in modern manufacturing, offering a unique combination of high strength, lightweight properties, and excellent corrosion resistance. As industries demand components that maximize performance while minimizing weight, aluminum forgings have emerged as a key solution. Jiangxi Hongdu Precision Machinery stands at the forefront of this industry, providing precision-engineered aluminum forgings that meet stringent quality standards and diverse industrial requirements.

Understanding the Aluminum Forging Process

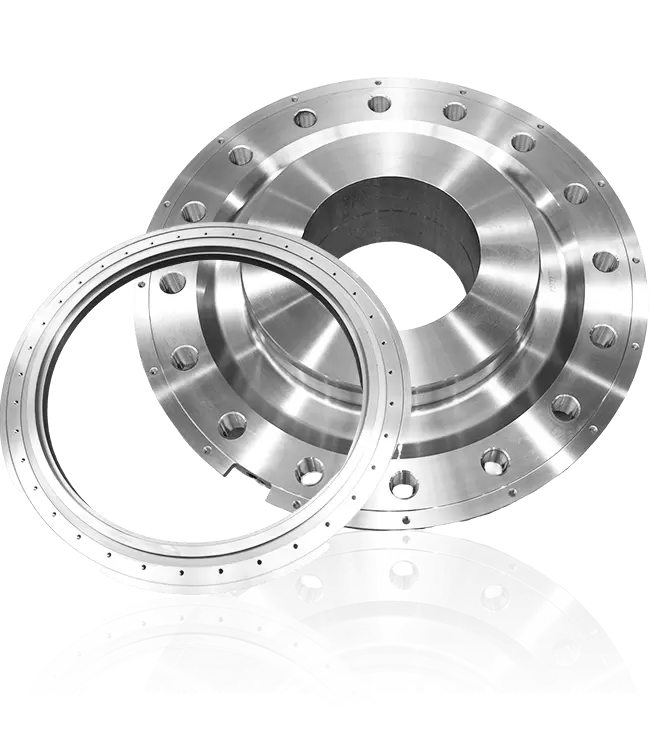

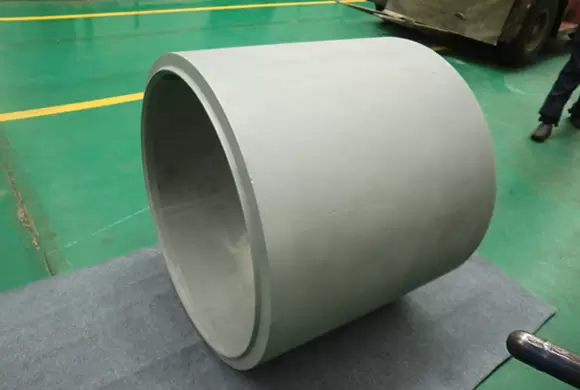

The process of creating aluminum forgings begins with the selection of high-grade aluminum alloys tailored to specific applications. The alloys are then subjected to precise heating, shaping, and cooling processes designed to optimize mechanical properties. Unlike casting, forging aligns the internal grain structure of the aluminum, enhancing strength, fatigue resistance, and durability. Modern techniques such as closed-die forging and precision CNC machining allow Jiangxi Hongdu Precision Machinery to produce complex components with exact tolerances, ensuring high reliability in demanding environments.

Key Advantages of Aluminum Forgings

Superior Strength-to-Weight Ratio: Aluminum forgings provide high structural integrity while remaining lightweight, essential for aerospace, automotive, and industrial applications.

Enhanced Durability: Forged aluminum demonstrates excellent fatigue resistance, reducing the likelihood of cracks or failure under repeated stress.

Corrosion Resistance: Aluminum’s natural oxide layer protects forged components from environmental degradation, extending service life.

Precision and Consistency: Advanced forging processes enable tight dimensional control, reducing the need for extensive post-processing and improving component repeatability.

Applications Across Multiple Industries

Aerospace: Aluminum forgings are critical for structural components, landing gear, and engine parts, where both strength and weight reduction are paramount.

Automotive: Lightweight forged aluminum parts contribute to fuel efficiency and emission reduction, used in chassis components, suspension systems, and engine mounts.

Industrial Machinery: Forged aluminum provides durability and precision for high-stress machinery parts, including gear housings, frames, and hydraulic components.

Electronics and Consumer Goods: Precision aluminum forgings serve in heat sinks, structural frames, and casings, delivering thermal efficiency and aesthetic appeal.

The Role of Jiangxi Hongdu Precision Machinery

Jiangxi Hongdu Precision Machinery excels in delivering high-quality aluminum forgings tailored to client specifications. With state-of-the-art facilities, stringent quality control, and a focus on research-driven innovation, the company ensures that each forging achieves optimal mechanical performance and longevity. Their expertise spans multiple sectors, making them a trusted partner for precision manufacturing solutions.

Future Trends in Aluminum Forgings

As industries evolve, the demand for lighter, stronger, and more durable components continues to rise. Advancements in alloy development, computer-aided forging simulations, and additive manufacturing integration are set to enhance the capabilities of aluminum forgings further. Companies like Jiangxi Hongdu Precision Machinery are positioned to lead this evolution by providing solutions that combine precision, efficiency, and sustainability.

Conclusion: Strategic Advantage Through Aluminum Forgings

In today’s competitive manufacturing landscape, aluminum forgings offer an unmatched balance of strength, weight savings, and reliability. Leveraging the expertise of Jiangxi Hongdu Precision Machinery ensures that businesses can access high-quality, precision-engineered components that drive performance, efficiency, and innovation across diverse industries. Investing in aluminum forgings is not merely a choice of material—it is a strategic decision to enhance product quality and maintain a competitive edge.