Home / Resources / Blogs / Industry News / High-Precision Ring Forging for Superior Dimensional Accuracy

High-Precision Ring Forging for Superior Dimensional Accuracy

In the modern industrial landscape, precision and reliability are critical to achieving consistent performance across a wide range of applications. One of the most important processes that directly influences the quality of high-strength components is ring forging. As industries such as aerospace, automotive, energy, and heavy machinery continue to demand components with tight tolerances and outstanding mechanical properties, high-precision ring forging has become the cornerstone of advanced manufacturing.

What is Ring Forging?

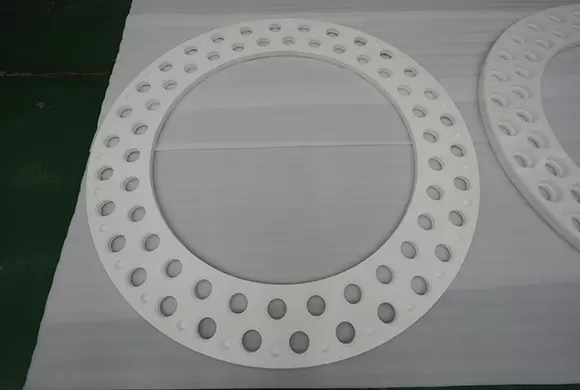

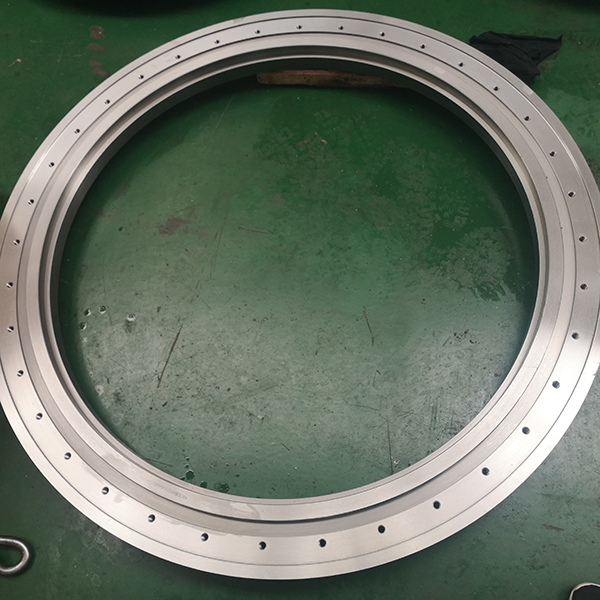

Ring forging is a specialized metalworking process used to produce seamless rolled rings with exceptional strength, durability, and accuracy. The process involves shaping a preform—typically a cylindrical piece of metal—into a ring by heating and applying compressive forces through forging presses and rolling machines.

Unlike other forming methods, forged rings deliver superior grain flow, reduced porosity, and improved fatigue resistance. These qualities make them indispensable for critical applications where structural integrity and dimensional precision are non-negotiable.

Importance of Dimensional Accuracy in Forged Rings

Dimensional accuracy is not just a technical specification—it is a performance guarantee. In industries like aerospace, power generation, and oil & gas, forged rings are often used in demanding environments where even minor dimensional deviations can compromise safety, efficiency, and operational reliability.

Key benefits of superior dimensional accuracy include:

Enhanced performance consistency – Precise dimensions ensure that forged rings fit perfectly into assemblies without extensive post-machining.

Reduced material waste – Less machining and fewer reworks lower costs and increase manufacturing efficiency.

Improved component lifespan – Proper dimensional control reduces stress concentrations and premature wear.

Compliance with global standards – Industries that operate under strict regulations, such as aerospace and defense, require forged components with certified dimensional tolerances.

Advancements in High-Precision Ring Forging

Modern forging facilities have integrated advanced technology to achieve tighter tolerances and higher accuracy in ring forging. Some of the key innovations include:

Computer-Aided Design (CAD) and Simulation

Virtual simulations allow manufacturers to model forging processes, predict material behavior, and optimize die design before production begins.

CNC-Controlled Rolling Mills

Computer numerical control ensures uniform deformation, maintaining precise wall thickness, diameter, and height throughout the forging process.

Automated Temperature Control

Precise heating and controlled cooling improve metallurgical properties while minimizing dimensional distortions.

Non-Destructive Testing (NDT) Techniques

Ultrasonic testing, magnetic particle inspection, and other NDT methods verify accuracy without compromising the integrity of the forged ring.

Robotic Handling and Monitoring Systems

Automation reduces human error, ensuring repeatability and consistency across large-scale production.

Applications of High-Precision Forged Rings

Because of their unmatched strength and dimensional control, forged rings are widely used in industries where safety, durability, and performance are critical:

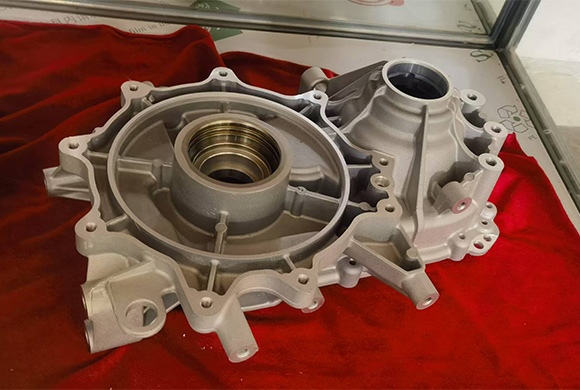

Aerospace Industry – Jet engines, landing gears, and turbine components demand rings with exceptional fatigue resistance and dimensional accuracy.

Automotive Industry – High-performance vehicles require forged rings for gear systems, bearings, and drive assemblies.

Energy Sector – Nuclear power plants and wind turbines use forged rings in generators, flanges, and critical structural parts.

Oil & Gas Industry – High-pressure pipelines, valves, and offshore drilling equipment rely on precision-forged rings for reliability.

Heavy Machinery – Industrial presses, construction equipment, and mining machinery utilize forged rings for strength and endurance.

Why Choose High-Precision Ring Forging?

High-precision ring forging is not just about manufacturing—it is about delivering performance. Companies that invest in this technology benefit from:

Unmatched strength-to-weight ratio – Forged rings maintain structural integrity without excessive weight.

Consistency across production – Every ring produced meets the same dimensional and quality standards.

Lower lifecycle costs – Reduced wear, fewer replacements, and minimal reworks cut long-term expenses.

Customizability – Forging allows for tailored designs, including varying diameters, wall thicknesses, and material grades.

Conclusion

High-precision ring forging for superior dimensional accuracy is more than a manufacturing process—it is the backbone of modern industry. From aerospace engines to power generation systems, forged rings deliver the reliability, safety, and performance required in the world’s most demanding applications. With continuous innovation in forging technology, manufacturers are setting new standards for accuracy, efficiency, and sustainability.

By choosing precision ring forging, industries not only secure top-quality components but also gain a competitive edge in today’s performance-driven marketplace.