Home / Resources / Blogs / Industry News / Achieving Perfection in Every Component: The Role of Casting Machining Accuracy in Modern Manufacturing

Achieving Perfection in Every Component: The Role of Casting Machining Accuracy in Modern Manufacturing

In high-performance manufacturing, casting machining accuracy plays a decisive role in determining the functionality, efficiency, and lifespan of mechanical components. From automotive and aerospace to energy and industrial equipment, precision in casting is not just a technical parameter—it’s a benchmark of quality and innovation.

At Jiangxi Hongdu Precision Machinery, casting is more than shaping metal—it’s a pursuit of perfection. Through continuous investment in advanced technology and process optimization, the company has set new standards for casting machining accuracy that meet the demands of today’s global industries.

1. Understanding Casting Machining Accuracy

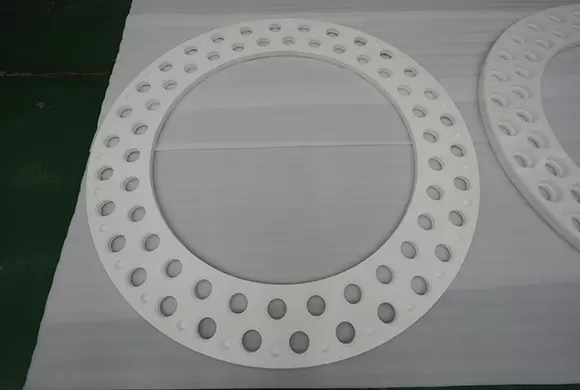

Casting machining accuracy refers to the degree to which a cast component’s actual dimensions, surface finish, and geometric tolerances align with its design specifications.

In manufacturing, this precision ensures that cast parts fit seamlessly into complex assemblies without additional machining or adjustment. It impacts performance, safety, and long-term reliability.

The key determinants of casting accuracy include:

Mold design and material stability

Thermal control during solidification

Shrinkage compensation calculations

Post-casting machining precision

Measurement and inspection technologies

Even minor deviations—measured in microns—can influence how components perform under high stress or dynamic conditions. Hence, achieving and maintaining tight tolerances is both a science and an art.

2. The Jiangxi Hongdu Advantage

As a leading manufacturer specializing in high-precision metal components, Jiangxi Hongdu Precision Machinery combines decades of foundry experience with cutting-edge machining technology to deliver castings that exceed industry expectations.

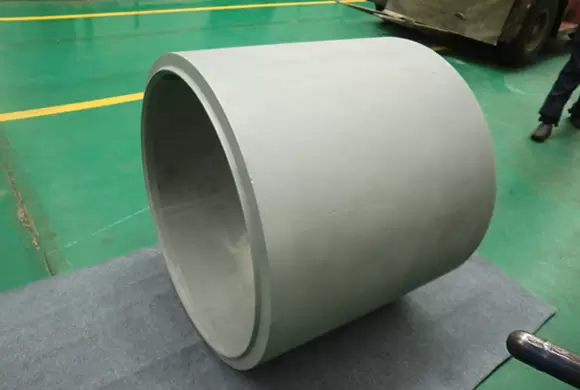

a. Advanced Casting Techniques

The company employs a range of modern casting methods, including:

Investment casting for complex geometries and fine finishes

Sand casting for large, durable components

Die casting for mass production with high dimensional consistency

Each process is carefully selected and optimized based on material properties, mechanical requirements, and customer specifications.

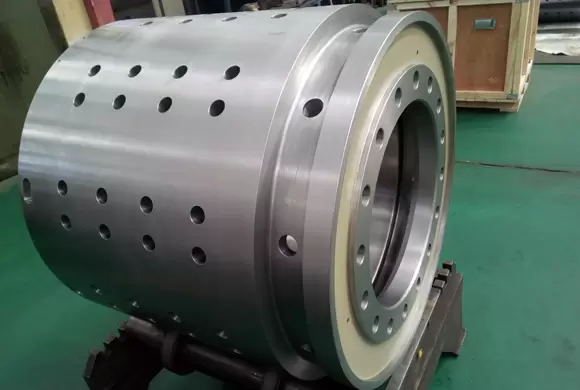

b. State-of-the-Art CNC Machining

After casting, components undergo precision CNC machining to achieve the final dimensional tolerances. Jiangxi Hongdu’s facilities are equipped with multi-axis machining centers capable of achieving sub-micron precision, ensuring every detail meets global standards.

c. Rigorous Quality Control

Quality assurance is at the core of Jiangxi Hongdu’s philosophy. Using CMM (Coordinate Measuring Machines), optical metrology, and surface roughness testing, the company verifies every stage of the process—mold creation, casting, machining, and final inspection. This meticulous approach guarantees consistent casting machining accuracy across all production batches.

3. Engineering Excellence Through Process Integration

One of Jiangxi Hongdu’s key strengths lies in its integrated casting and machining workflow. Unlike traditional production chains that separate foundry and machining operations, Hongdu unites both under one roof, allowing for:

Reduced dimensional deviations through controlled workflow continuity

Faster turnaround times without external logistics delays

Improved traceability and defect prevention

Enhanced design flexibility for prototype and batch production

This integration ensures that every part not only meets but anticipates the precision requirements of next-generation manufacturing.

4. Material Science: The Backbone of Accuracy

Achieving tight casting machining accuracy begins with selecting the right material and understanding its metallurgical behavior. Jiangxi Hongdu specializes in casting materials such as:

High-grade aluminum alloys for lightweight precision components

Stainless and carbon steels for high-strength structural applications

Ductile and gray iron for durability and vibration absorption

Nickel and copper-based alloys for corrosion resistance and heat tolerance

By controlling alloy composition, grain refinement, and cooling rates, Hongdu ensures predictable shrinkage patterns and consistent structural integrity—crucial to post-casting precision.

5. Applications: Precision Across Industries

Jiangxi Hongdu’s precision cast and machined parts are used in a wide spectrum of industrial sectors:

Automotive: Engine housings, transmission cases, and brake components

Aerospace: Turbine casings and structural brackets requiring high dimensional stability

Energy: Valve bodies, pump housings, and turbine components

Machinery: Hydraulic manifolds, bearings, and gearbox housings

For OEMs and B2B partners worldwide, Hongdu’s products represent a balance of accuracy, durability, and cost efficiency, backed by robust production capacity and consistent delivery timelines.

Conclusion

In today’s world of high-performance machinery, casting machining accuracy is not just a competitive advantage—it’s an industrial necessity.

Jiangxi Hongdu Precision Machinery stands at the forefront of this precision revolution, combining metallurgical expertise, advanced CNC machining, and integrated quality systems to deliver cast components that redefine accuracy and reliability.

Whether it’s for automotive, aerospace, or heavy industry applications, choosing Jiangxi Hongdu means choosing a partner committed to engineering excellence from concept to completion.