Home / Resources / Blogs / Industry News / From Strength to Longevity: The Benefits of Stainless Steel Ring Forged Parts

From Strength to Longevity: The Benefits of Stainless Steel Ring Forged Parts

In modern industrial applications, the demand for components that combine durability, precision, and performance has never been higher. Stainless steel ring forged parts have emerged as critical elements in machinery, automotive, and engineering industries due to their exceptional mechanical properties and long service life. Jiangxi Hongdu Precision Machinery, a leading manufacturer of high-quality forged components, specializes in producing stainless steel ring forged parts that meet rigorous industrial standards and provide reliable performance across diverse applications.

1. Understanding Stainless Steel Ring Forged Parts

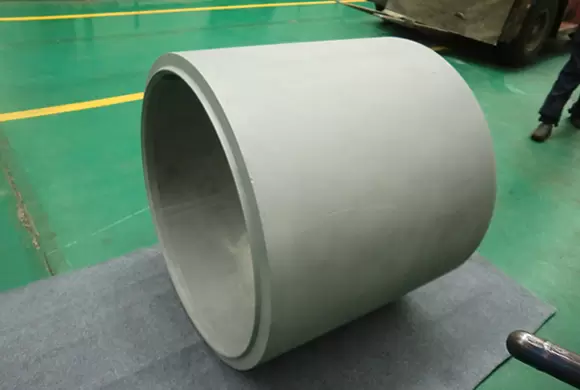

aStainless steel ring forged parts are components manufactured through a forging process that shapes stainless steel into circular forms with superior strength and uniform structure. Unlike cast or machined parts, forged rings exhibit a refined grain structure, which enhances their mechanical properties and resistance to fatigue, impact, and wear.

Key features of Jiangxi Hongdu’s stainless steel ring forged parts include:

High Mechanical Strength: Optimized for heavy-duty and high-stress applications.

Uniform Grain Structure: Improves durability and resistance to cracking under pressure.

Precision Dimensions: Manufactured with tight tolerances to ensure perfect fit in assemblies.

Corrosion Resistance: Stainless steel material prevents rust and chemical degradation.

These attributes make stainless steel ring forged parts ideal for applications demanding both precision and durability.

2. Advantages of Stainless Steel Ring Forged Parts

a. Enhanced Strength and Reliability

Forging improves the internal structure of stainless steel, resulting in higher tensile strength, fatigue resistance, and impact tolerance. This ensures that Jiangxi Hongdu’s forged rings can endure extreme mechanical stress without deforming, making them suitable for critical components in machinery and automotive assemblies.

b. Longevity and Reduced Maintenance

Stainless steel’s inherent corrosion resistance, combined with the superior toughness of forged parts, leads to extended service life. Components maintain structural integrity over time, reducing downtime and maintenance costs in industrial operations.

c. High-Precision Fit for Complex Assemblies

Jiangxi Hongdu utilizes advanced forging and machining technologies to achieve precise dimensions. This ensures that each stainless steel ring forged part integrates seamlessly into complex mechanical systems, contributing to optimal performance and operational efficiency.

d. Resistance to Harsh Environments

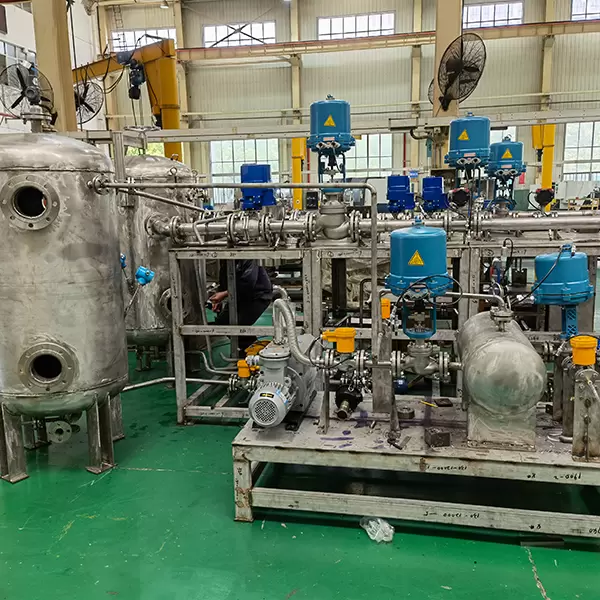

From chemical processing plants to marine and automotive applications, stainless steel ring forged parts perform reliably in environments characterized by high temperatures, corrosive substances, and mechanical stress.

3. Applications Across Industries

The versatility of stainless steel ring forged parts makes them indispensable in various sectors:

Automotive Industry: Gears, bearings, and axle components that require high strength and precision.

Heavy Machinery: Components in construction and mining equipment exposed to high load and impact.

Energy Sector: Parts for turbines, pumps, and valves in power generation and oil & gas industries.

Aerospace Engineering: Critical structural and mechanical elements requiring fatigue resistance and precision.

Jiangxi Hongdu Precision Machinery tailors its production to meet the specific requirements of these industries, ensuring that each forged ring delivers consistent quality and performance.

4. Technological Innovations by Jiangxi Hongdu

Jiangxi Hongdu integrates advanced technologies in the manufacturing of stainless steel ring forged parts:

Controlled Forging Process: Optimizes grain flow for maximum mechanical strength.

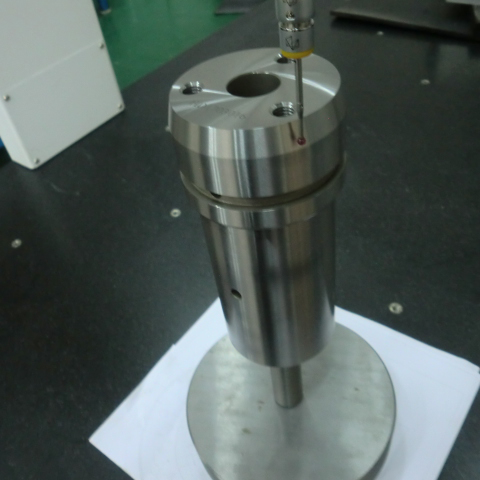

Precision CNC Machining: Ensures tight tolerances and accurate dimensions.

Advanced Heat Treatment: Enhances hardness, toughness, and corrosion resistance.

Quality Assurance Testing: Includes ultrasonic, magnetic particle, and dimensional inspections to guarantee reliability.

These innovations ensure that Jiangxi Hongdu’s forged rings maintain high performance under demanding operational conditions.

5. Benefits of Partnering with Jiangxi Hongdu

Expertise in Precision Forging: Decades of experience in producing high-performance components.

Customizable Solutions: Ability to tailor forged parts to specific design and material requirements.

Global Standards Compliance: Products meet ISO and other international quality standards.

Reliable Supply Chain: Consistent delivery and technical support for industrial clients worldwide.

Choosing Jiangxi Hongdu’s stainless steel ring forged parts ensures reliable, durable, and high-performance components that support operational efficiency and long-term equipment life.

Conclusion

Stainless steel ring forged parts are essential for industries requiring strength, precision, and longevity in their components. By leveraging the superior mechanical properties of forged stainless steel, Jiangxi Hongdu Precision Machinery provides parts that withstand extreme conditions, reduce maintenance costs, and optimize operational performance. Investing in high-quality forged components is a strategic choice that enhances machinery reliability and ensures long-term success in demanding industrial applications.