Home / Resources / Blogs / Industry News / Advanced Axis Component Processing Solutions for High-Accuracy Manufacturing

Advanced Axis Component Processing Solutions for High-Accuracy Manufacturing

In the era of intelligent manufacturing and precision engineering, axis component processing stands as one of the most critical stages in modern industrial production. Whether in aerospace, automotive, robotics, or heavy equipment manufacturing, the demand for high-precision axis components continues to grow rapidly. These components form the mechanical backbone of countless motion systems, where even the slightest deviation can affect the overall performance and reliability of the final product.

As an experienced manufacturer in precision machining, Jiangxi Hongdu Precision Machinery specializes in providing advanced axis component processing solutions designed to achieve exceptional dimensional accuracy, smooth surface finishes, and outstanding durability.

Precision Engineering at the Core of Axis Component Processing

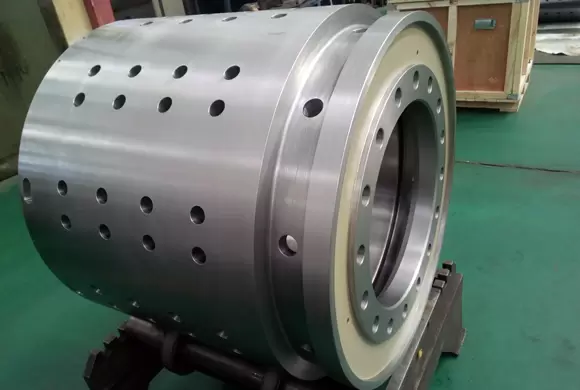

Axis components are vital in transmitting torque, bearing loads, and maintaining alignment in rotating mechanical systems. The processing of these parts involves multi-axis machining, advanced CNC technology, and strict quality control to ensure consistent precision across every production stage.

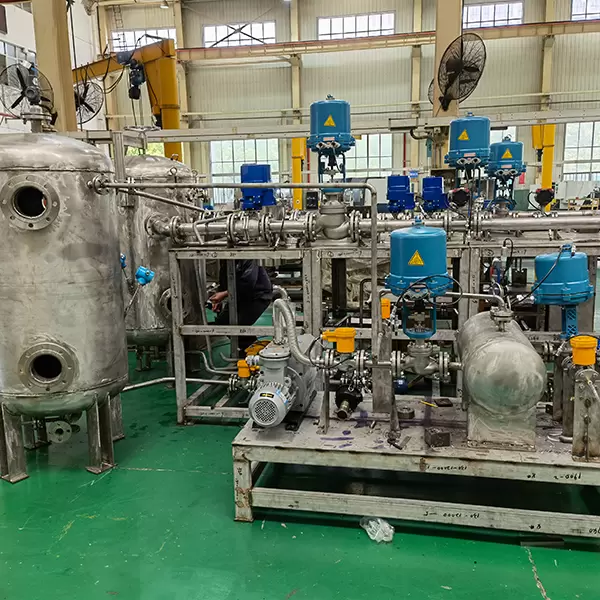

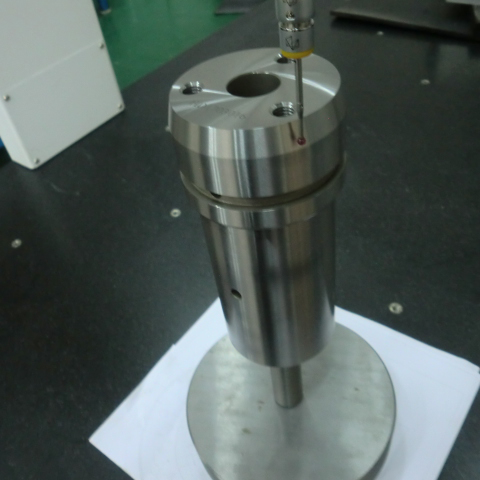

At Jiangxi Hongdu Precision Machinery, every process—from raw material selection to final inspection—is carefully monitored to ensure superior product quality. The company utilizes multi-axis CNC machining centers, high-precision grinding machines, and automated measuring equipment to achieve tolerances within microns. This level of precision guarantees the smooth operation and long-term stability of machinery across industries.

Advanced Technology for Complex Geometries

As products evolve toward miniaturization and complexity, axis component processing has also advanced significantly. Jiangxi Hongdu Precision Machinery has adopted a combination of five-axis machining technology, CNC turning-milling integration, and automated process simulation to meet the diverse requirements of different industries.

This enables the company to manufacture both standard and custom axis components, including:

Drive shafts and motor spindles

Transmission and steering system axes

Robotic joint shafts

High-speed precision rotors

Heavy-duty industrial axis assemblies

Through digitalized process control and intelligent programming, Jiangxi Hongdu ensures optimal cutting paths, reduced tool wear, and improved material utilization—leading to enhanced productivity and cost efficiency.

Quality Assurance and Consistency You Can Trust

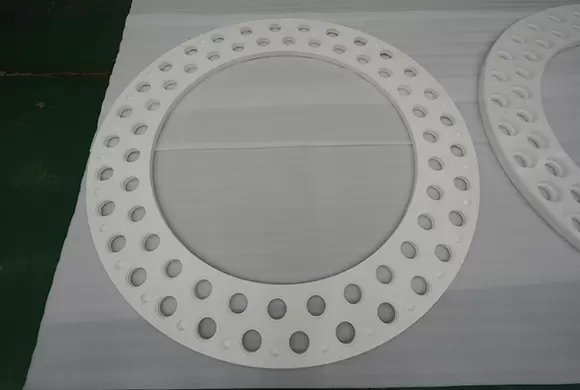

In axis component processing, quality consistency is as important as precision. Jiangxi Hongdu Precision Machinery follows quality management system, integrating advanced metrology and inspection techniques throughout production. Each part undergoes:

Dimensional measurement using coordinate measuring machines (CMM)

Surface roughness and hardness testing

Concentricity and roundness evaluation

Dynamic balance verification for rotating components

These meticulous quality controls ensure that every axis component leaving the factory meets strict international standards and performs flawlessly in its intended application.

Customized Axis Component Processing for Industry-Specific Needs

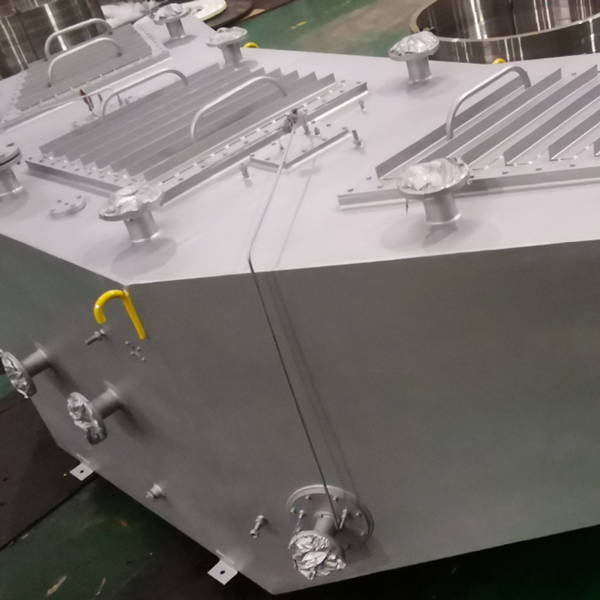

Different industries require different levels of precision and mechanical performance. Jiangxi Hongdu Precision Machinery provides customized processing services based on clients’ drawings, material requirements, and operational conditions. Whether the project demands stainless steel, aluminum, titanium, or alloy materials, Hongdu’s engineering team optimizes machining parameters to balance strength, weight, and cost.

Additionally, the company offers surface finishing solutions such as plating, anodizing, and heat treatment to further enhance wear resistance and corrosion protection, ensuring the components perform reliably even under extreme conditions.

Driving Manufacturing Excellence with Jiangxi Hongdu Precision Machinery

With years of expertise in axis component manufacturing, Jiangxi Hongdu Precision Machinery continues to push the boundaries of precision engineering. By combining advanced processing technologies with a strong commitment to quality, the company has earned the trust of partners worldwide.

Whether for high-speed automation systems, aerospace actuators, or industrial machinery, Jiangxi Hongdu provides tailored machining solutions that help customers achieve higher performance and longer product lifecycles.

Through continuous innovation and process optimization, Jiangxi Hongdu Precision Machinery stands as a reliable partner for manufacturers seeking precision, durability, and efficiency in every axis component.

Conclusion

In modern manufacturing, axis component processing is more than just machining—it is the foundation of reliability and accuracy in mechanical systems. Jiangxi Hongdu Precision Machinery continues to lead the industry with its advanced equipment, skilled workforce, and unwavering dedication to quality excellence.

By delivering high-performance, custom-engineered axis components, Hongdu empowers manufacturers to achieve new levels of efficiency and precision in production.