Home / Resources / Blogs / Industry News / Precision in Motion: How Hongdu Elevates the Processing of Mechanical Equipment Components

Precision in Motion: How Hongdu Elevates the Processing of Mechanical Equipment Components

The processing of mechanical equipment components is the cornerstone of today’s manufacturing world. Every machine, from industrial turbines to precision medical devices, relies on accurately processed components to perform at peak efficiency. The precision, consistency, and durability of these parts determine the overall reliability and service life of the equipment.

As industrial standards continue to evolve, manufacturers face the challenge of achieving greater precision while improving efficiency and sustainability. Hongdu, a leading name in precision mechanical component processing, has set itself apart through advanced engineering, intelligent manufacturing systems, and a relentless pursuit of quality.

Precision Engineering: The Core of Component Processing

At its heart, the processing of mechanical equipment components requires a fusion of advanced technology and deep engineering expertise. Hongdu understands that precision is not simply about tight tolerances—it’s about achieving perfect harmony between design intent and production execution.

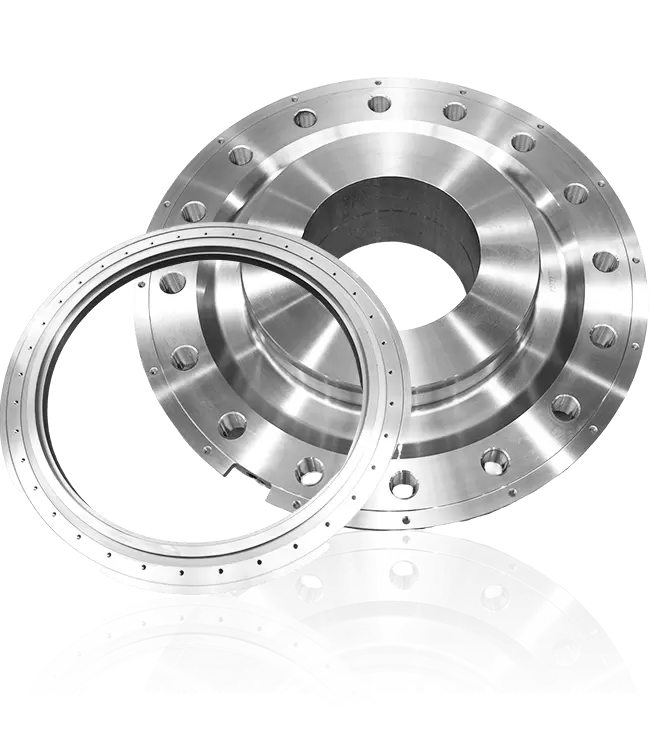

The company employs cutting-edge CNC machining, grinding, EDM (Electrical Discharge Machining), and laser processing technologies to achieve sub-micron accuracy. Each component is meticulously monitored using coordinate measuring machines (CMMs) and optical inspection systems to ensure exact dimensional compliance.

This precision guarantees smooth mechanical motion, reduces vibration, minimizes wear, and enhances the energy efficiency of industrial systems. For Hongdu, every micron matters.

Advanced Materials and Surface Treatments

The performance of mechanical equipment depends not only on dimensional accuracy but also on the material’s properties and surface integrity. Hongdu’s strength lies in its ability to process high-performance alloys, titanium, stainless steel, and aluminum composites used in demanding applications.

To extend durability and resistance to harsh conditions, Hongdu integrates advanced heat treatment, nitriding, and PVD coating techniques. These processes improve surface hardness, corrosion resistance, and fatigue strength—ensuring that each part maintains its performance under extreme mechanical loads or high temperatures.

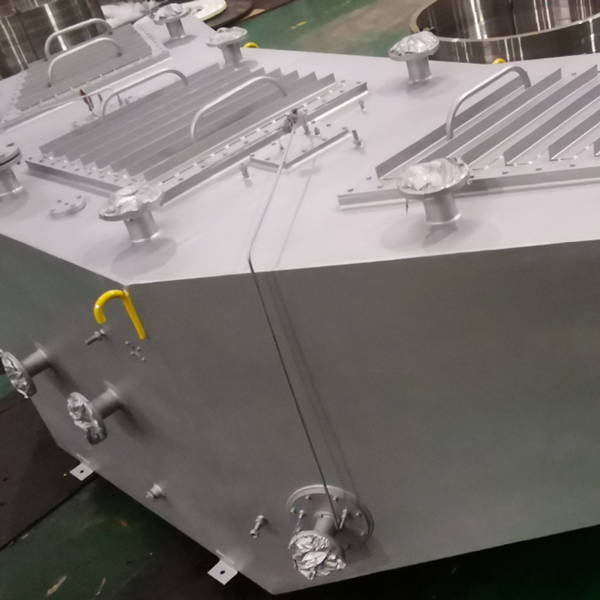

Whether used in automotive transmissions, industrial compressors, or energy equipment, Hongdu’s processed components deliver stability, longevity, and consistent mechanical behavior.

Intelligent Manufacturing and Digital Integration

In the age of Industry 4.0, the processing of mechanical equipment components has entered a new era of digital transformation. Hongdu integrates CAD/CAM systems, digital twins, and IoT-based production monitoring to create an intelligent and data-driven manufacturing environment.

Before production even begins, digital simulation allows engineers to optimize machining paths, predict tool wear, and improve cycle efficiency. During manufacturing, real-time monitoring systems track every variable—cutting force, temperature, and vibration—to maintain precision.

This digital integration not only enhances production accuracy but also reduces downtime, waste, and costs, giving Hongdu’s customers a clear competitive edge.

Customization and Complex Geometry Machining

As machinery becomes more specialized, so does the need for customized component processing. Hongdu provides tailored solutions that meet unique design specifications, from high-speed spindles and precision shafts to complex housing components.

Through five-axis machining and multi-tasking centers, Hongdu can produce intricate geometries that traditional machining methods cannot achieve. The company’s engineering team collaborates closely with clients, ensuring that every component is optimized for its functional and structural requirements.

This customization capability allows manufacturers to innovate faster, improve system integration, and reduce assembly complexity—all while maintaining uncompromising precision.

Quality Control and Process Validation

Each part undergoes statistical process control (SPC), non-destructive testing (NDT), and metallurgical analysis to guarantee full traceability and compliance. Instead of inspecting quality after production, Hongdu builds quality into the process itself—ensuring that every cut, every tolerance, and every finish meets the highest engineering standards.

This commitment to validation and repeatability gives customers confidence that Hongdu’s components will perform reliably over long operational lifetimes.

Sustainability and Green Manufacturing

In modern industry, sustainability has become inseparable from innovation. Hongdu embraces eco-efficient machining, recyclable lubricants, and closed-loop coolant systems to minimize environmental impact during the processing of mechanical equipment components.

The company also invests in energy-efficient CNC systems and additive-subtractive hybrid manufacturing, enabling reduced material waste and carbon emissions. By combining precision engineering with sustainable practices, Hongdu demonstrates that advanced manufacturing and environmental responsibility can coexist harmoniously.

Conclusion

The processing of mechanical equipment components defines the standard of excellence in modern machinery. As industries demand higher accuracy, lighter structures, and longer service life, Hongdu continues to lead through innovation, technical mastery, and a deep understanding of materials and motion.

From concept to final assembly, Hongdu transforms raw metal into precision-engineered performance. Each component reflects not just a product—but a promise of reliability, precision, and lasting mechanical strength.

Hongdu remains a trusted global partner for companies seeking excellence in the processing of mechanical equipment components, driving the next generation of industrial efficiency and innovation.